Preparation method of gellan gum with high gel strength, high viscosity and high acyl groups

A Gellan Gum, High Gel Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

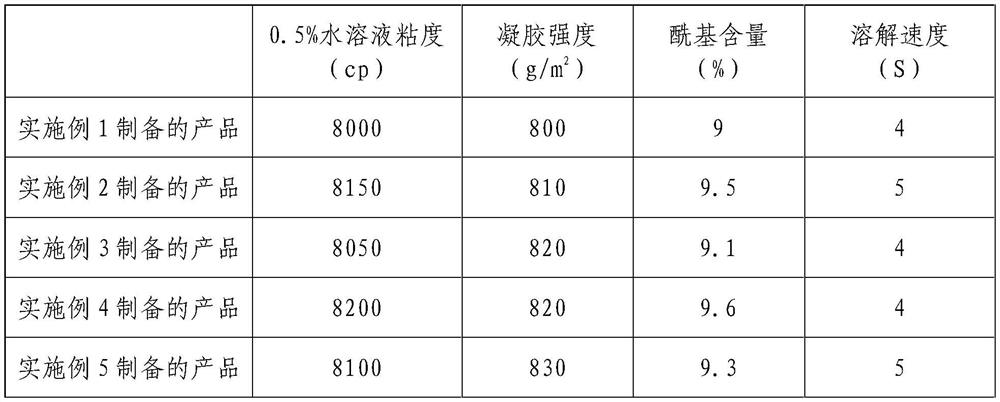

Image

Examples

Embodiment 1

[0055] The preparation method of gellan gum with high gel strength, high viscosity and high acyl group comprises the following process steps:

[0056] A. Inoculate Sphingomonas sp. CGMCC No. 14238 according to the inoculation amount of 10%-20% to a high carbon-nitrogen ratio containing carbon source, nitrogen source and essential nutrients after sterilization in fermentation medium;

[0057] B, adjust the pH=7.0 of the fermentation medium, carry out aeration fermentation under the condition that the temperature is 35°C and the ventilation volume is 0.3vvm;

[0058] C, ferment for 20-30 hours and add sterile water and oxygen-carrying agent;

[0059] D. When the viscosity of the culture medium no longer increases or the fermentation period is less than or equal to 50 hours, the fermentation ends;

[0060] E. After the fermentation, the fermented liquid is post-extracted to prepare gellan gum with high gel strength, high viscosity and high acyl group.

[0061] In the middle st...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is:

[0070] B, adjust the pH=7.5 of fermentation medium, carry out aeration fermentation under the condition that temperature is 37 ℃, and ventilation volume is 0.8vvm;

[0071] Fermentation medium in steps A, B is made up of the raw material of following mass percentage:

[0072] Glucose or maltose 4%; soybean protein isolate 0.3%; sodium nitrate 0.2%; calcium carbonate 0.15%; potassium dihydrogen phosphate 0.25%; silicone defoamer 0.15%; the balance is sterile water.

[0073] In step C, the process condition of filling sterile water and oxygen-carrying agent is:

[0074] For 20-30 hours of fermentation, sterile water accounting for 5% of the volume of the fermentation broth and an oxygen-carrying agent accounting for 0.6% of the volume of the fermentation broth are added, and the oxygen-carrying agent is selected from Tween 20.

[0075] The fermentation broth after the fermentation in step D is adjusted to pH=...

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] B, adjust the pH=7.2 of fermentation medium, carry out aeration fermentation under the condition that temperature is 36 ℃, and ventilation volume is 0.5vvm;

[0079] Fermentation medium in steps A, B is made up of the raw material of following mass percentage:

[0080] Glucose or maltose 3.5%; soybean protein isolate 0.2%; sodium nitrate 0.15%; calcium carbonate 0.12%; potassium dihydrogen phosphate 0.2%;

[0081] In step C, the process condition of filling sterile water and oxygen-carrying agent is:

[0082] For 20-30 hours of fermentation, sterile water accounting for 4% of the volume of the fermentation broth and an oxygen-carrying agent accounting for 0.5% of the volume of the fermentation broth are added, and the oxygen-carrying agent is selected from the combination of hydrogen peroxide and Tween 20.

[0083] The fermentation broth after the fermentation in step D is adjusted to pH=5.0-6.0 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com