Hard carbon negative electrode material

A negative electrode material and hard carbon technology, applied in the field of new energy, can solve the problems of little improvement in important performance such as safety and life, poor comprehensive performance of lithium batteries, and short life, so as to enhance the electronic interaction rate, improve battery performance, The effect of improving discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

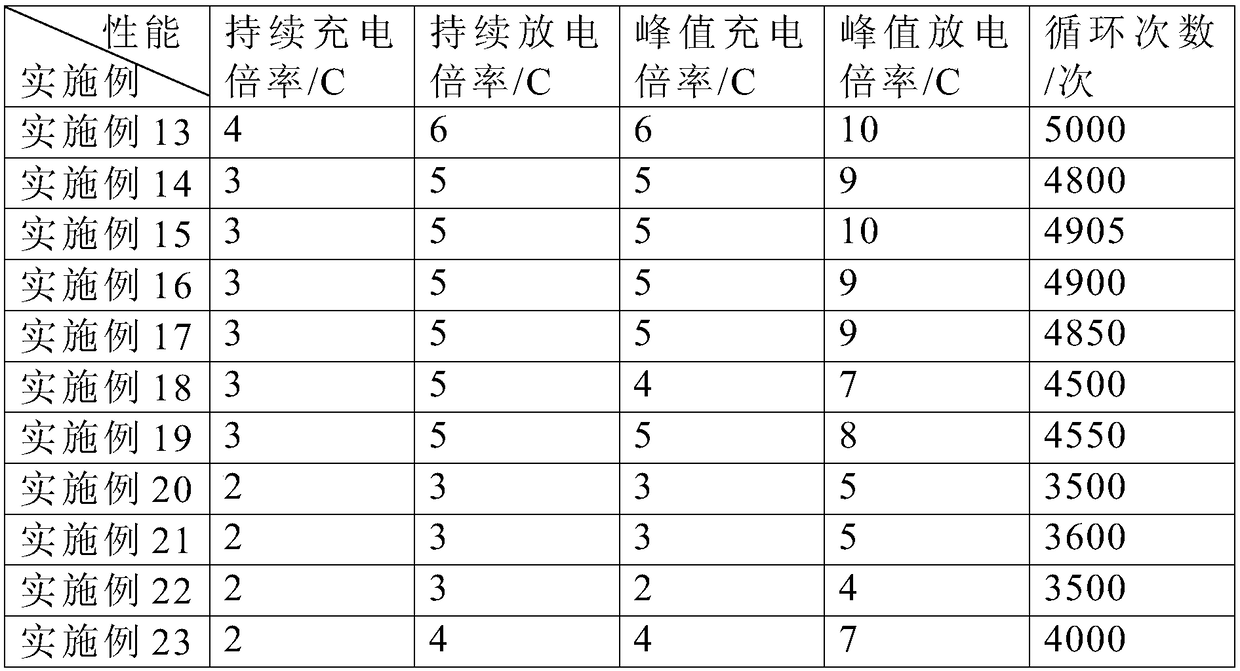

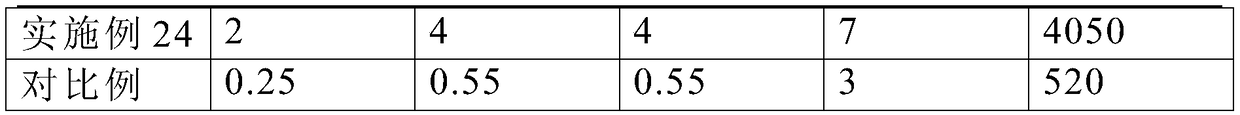

Examples

Embodiment 1

[0033] Pretreatment: Weigh raw materials according to the above-mentioned negative electrode material, including the following components in parts by weight: 50 parts of vanadium pentoxide, 10 parts of carbon source, 3 parts of boron powder, 3 parts of filler, wherein the carbon source is rhamnose, A mixture of lactose and maltose, the filler is a mixture of tin nitride, silicon nitride and silver chloride, the carbon source is dissolved in water, put into container 1, and vanadium pentoxide is put into container 2;

[0034] Oil-water mixing heat: add 25ml of deionized water to containers 1 and 2 respectively, then add 8 drops of mixed oil of peanut oil, linseed oil and castor oil, put containers 1 and 2 in a closed device, heat to 110°C and keep warm 45s, then pour the solution in container 1 into container 2, add boron powder, continue to heat up to 250°C and keep warm for 1.3h, cool naturally after the reaction is complete, filter and vacuum dry at 90°C for 9h to obtain a se...

Embodiment 2

[0037] Pretreatment: Weigh raw materials according to the above-mentioned negative electrode material, including the following components in parts by weight: 45 parts of vanadium pentoxide, 9 parts of carbon source, 2 parts of boron powder, 1 part of filler, wherein the carbon source is maltose, and the filler For tin nitride, the carbon source is dissolved in water, packed in container 1, and vanadium pentoxide is packed in container 2;

[0038] Oil-water mixing heat: add 25ml of deionized water to containers 1 and 2 respectively, then add 8 drops of mixed oil of peanut oil, linseed oil and castor oil, put containers 1 and 2 in a closed device, heat to 110°C and keep warm 45s, then pour the solution in container 1 into container 2, add boron powder, continue to heat up to 250°C and keep warm for 1.3h, cool naturally after the reaction is complete, filter and vacuum dry at 90°C for 9h to obtain a semi-finished negative electrode material;

[0039]Post-processing: Deposit tin n...

Embodiment 3

[0041] Pretreatment: Weigh raw materials according to the above-mentioned negative electrode material, including the following components in parts by weight: 55 parts of vanadium pentoxide, 11 parts of carbon source, 4 parts of boron powder, and 5 parts of filler, wherein the carbon source is lactose, and the filler For silicon nitride, the carbon source is dissolved in water, packed in container 1, and vanadium pentoxide is packed in container 2;

[0042] Oil-water mixing heat: add 25ml of deionized water to containers 1 and 2 respectively, then add 8 drops of mixed oil of peanut oil, linseed oil and castor oil, put containers 1 and 2 in a closed device, heat to 110°C and keep warm 45s, then pour the solution in container 1 into container 2, add boron powder, continue to heat up to 250°C and keep warm for 1.3h, cool naturally after the reaction is complete, filter and vacuum dry at 90°C for 9h to obtain a semi-finished negative electrode material;

[0043] Post-processing: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com