Minced shrimp block and green cucumber white bean jelly and preparation method thereof

A technology for white jelly powder and cucumber, which is applied in the directions of food science, food ingredients as taste improvers, food ingredients as taste improvers, etc., can solve the problems of reducing the nutritional value of finished products, low nutritional value of white jelly powder, and reducing the nutritional value of food. , to achieve the effect of refreshing and not greasy taste, delaying aging, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

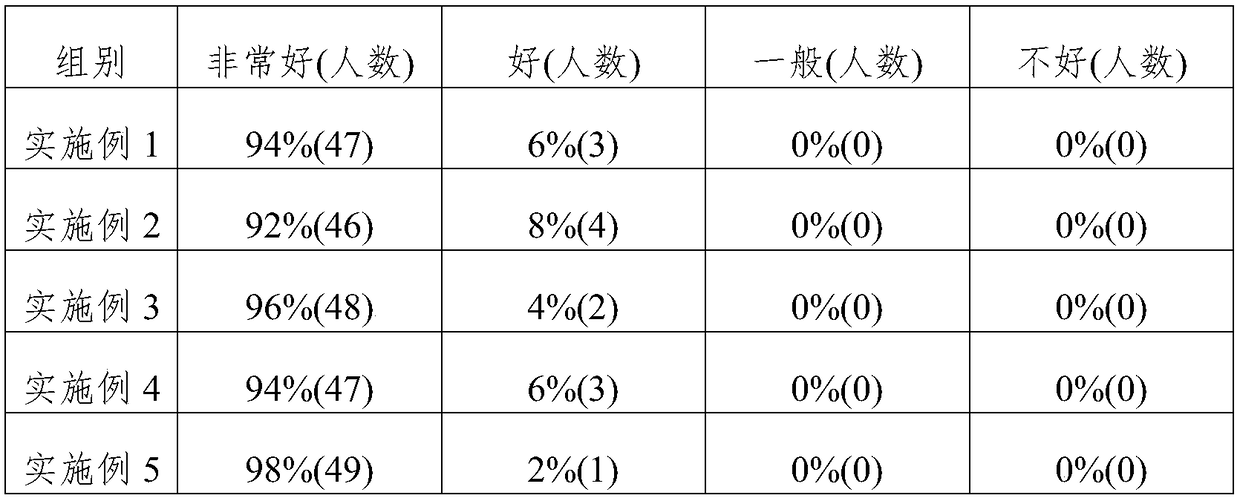

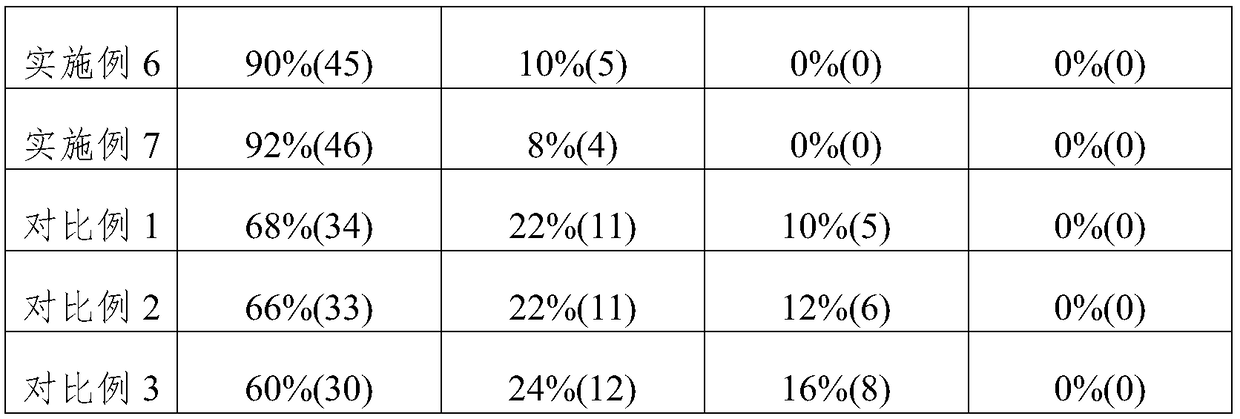

Embodiment 1

[0042] The invention discloses a cucumber white jelly with minced shrimp, which is prepared from the following raw materials in parts by weight: 25 parts of jelly, 35 parts of fresh shrimp, 22 parts of cassava flour, 5 parts of cucumber, 0.6 part of food additive and 0.6 part of seasoning.

[0043] Further, the seasoning is sugar, salt, black pepper and soy sauce, and the ratio between sugar, salt, black pepper and soy sauce is 1:1:1:1; the food additive is a compound thickener, Sucralose; the compound thickener is gelatine powder.

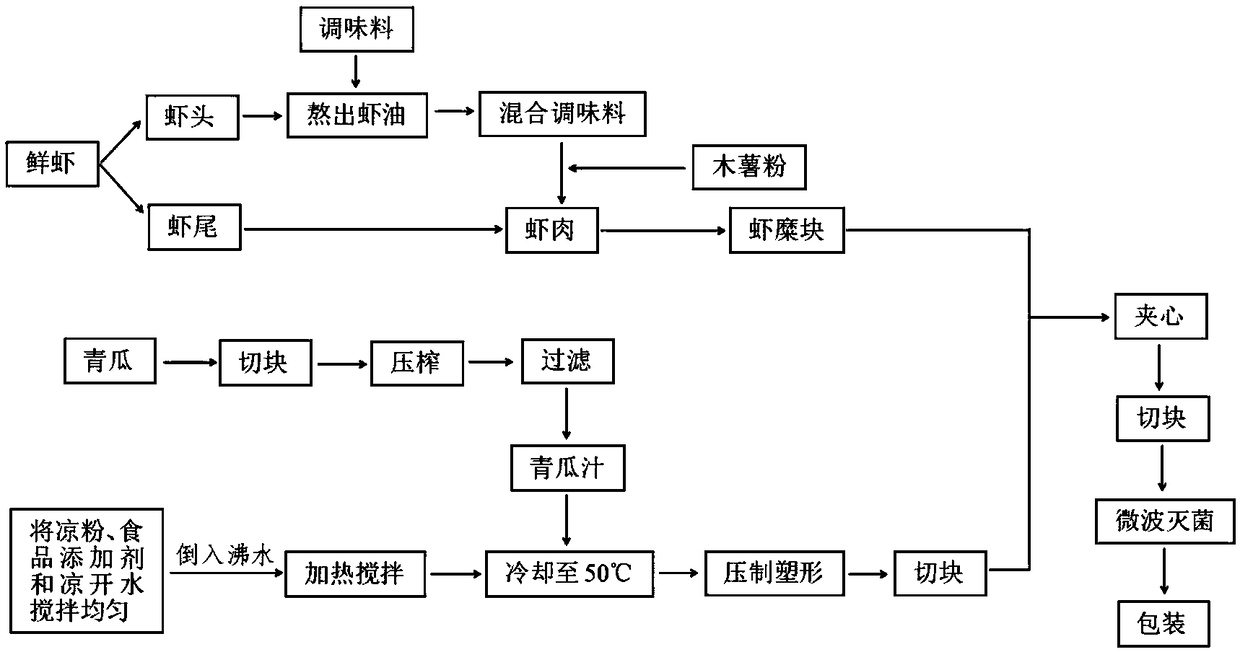

[0044] A preparation method of minced shrimp block cucumber white jelly as described above, comprising the following steps:

[0045] (1) Preparation of mixed seasoning: remove impurities and clean the fresh shrimp, separate the shrimp head from the tail, boil the shrimp head to get the shrimp oil at a low temperature of 55°C, and add the seasoning after cooling to room temperature. Stir well to get mixed seasoning, remove the shrimp tail and shri...

Embodiment 2

[0051] The invention discloses a cucumber jelly with minced shrimp, which is prepared from the following raw materials in parts by weight: 33 parts of jelly, 45 parts of fresh shrimp, 30 parts of cassava flour, 12 parts of cucumber, 1 part of food additive and 1 part of seasoning.

[0052] Further, the seasoning is sugar, salt, black pepper and soy sauce, and the ratio between sugar, salt, black pepper and soy sauce is 2:1:2:3; the food additive is a compound thickener, Potassium sorbate; The compound thickener is gelatine powder.

[0053] A preparation method of minced shrimp block cucumber white jelly as described above, comprising the following steps:

[0054] (1) Preparation of mixed seasoning: After the fresh shrimps are cleaned and cleaned, the heads and tails of the shrimps are separated, and the shrimp oil is boiled out of the heads of the shrimps at a low temperature of 75°C. After cooling to room temperature, the seasonings are added. Stir well to get mixed seasonin...

Embodiment 3

[0060] A cucumber jelly with minced shrimp is prepared from the following raw materials in parts by weight: 26 parts of jelly, 36 parts of fresh shrimp, 23 parts of cassava flour, 6 parts of cucumber, 0.7 part of food additive and 0.7 part of seasoning.

[0061] Further, the seasoning is sugar, salt, black pepper and soy sauce, and the ratio between sugar, salt, black pepper and soy sauce is 1.2:1:1.2:1.5; the food additive is a compound thickener, Sucralose, potassium sorbate; the compound thickener is gelatine powder.

[0062] A preparation method of minced shrimp block cucumber white jelly as described above, comprising the following steps:

[0063] (1) Preparation of mixed seasoning: remove impurities and clean the fresh shrimp, separate the shrimp head from the tail, boil the shrimp head to get the shrimp oil at a low temperature of 60°C, cool to room temperature, add seasoning, Stir well to get mixed seasoning, remove the shrimp tail and shrimp shell to get the shrimp m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com