Catalyst for cracking domestic sludge, preparation method thereof and method for treating domestic sludge

A technology of domestic sludge and catalyst, which is applied in biological sludge treatment, catalyst activation/preparation, sludge treatment, etc. The problems of low energy efficiency in the conversion of mud organic matter, to achieve the effect of simple pretreatment process, reducing non-specific absorption, and saving the amount of enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

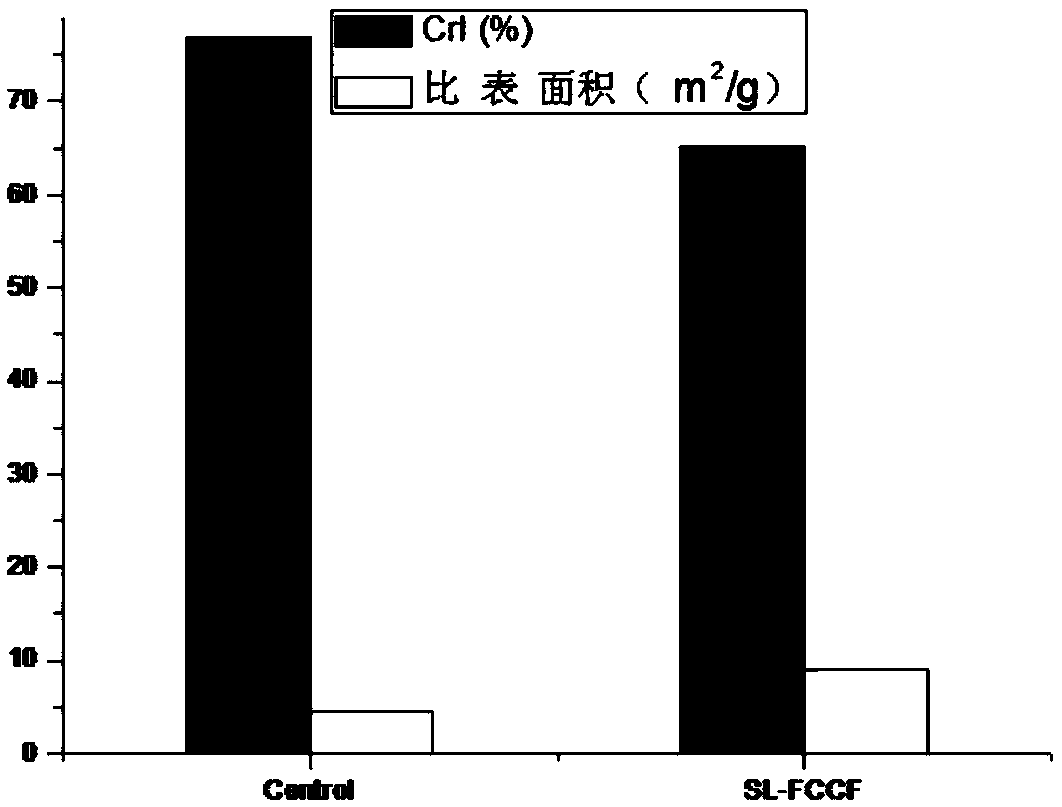

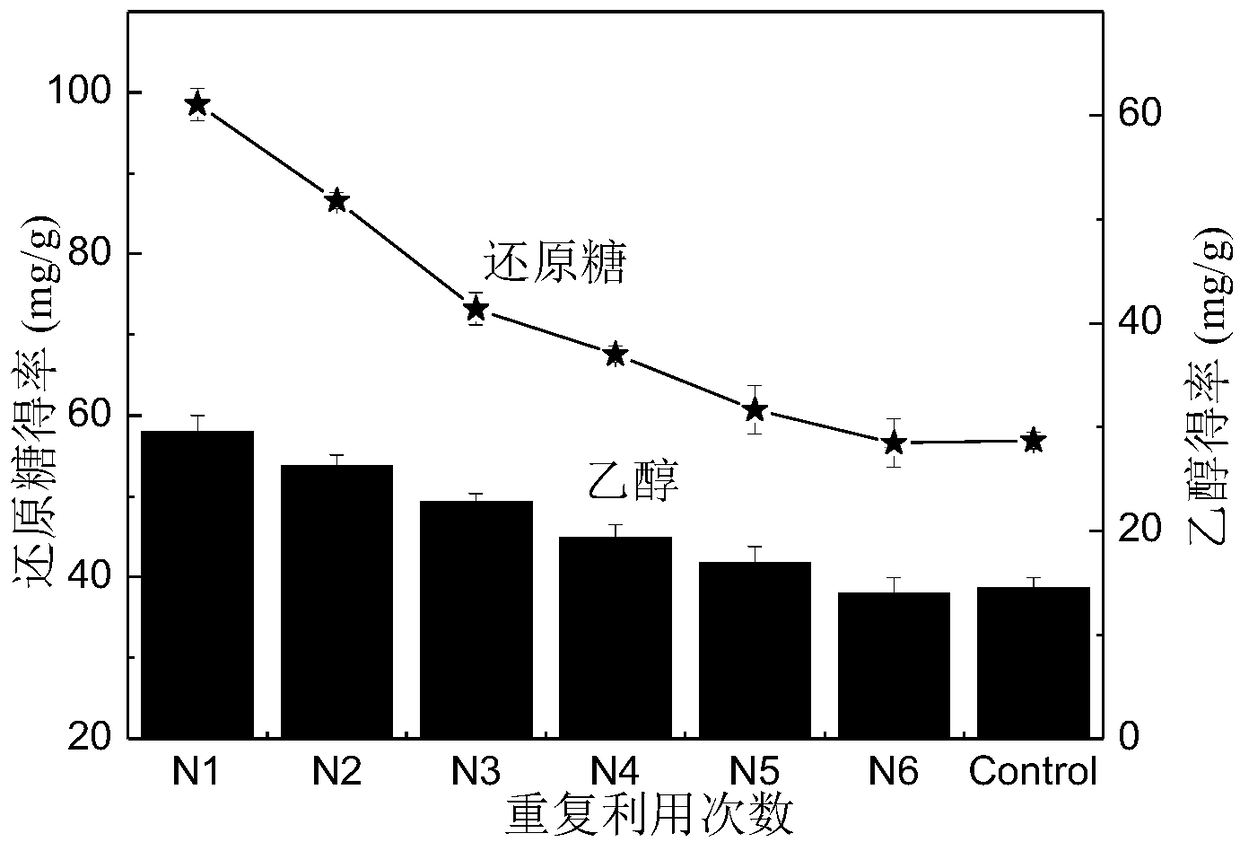

[0033] The synthetic method of SL-FCCF catalyst disclosed by the invention comprises the steps:

[0034] 1) According to the molar ratio of Fe 2+ :Co 2+ :Fe 3+ = 1:1:5 ratio FeCl 2 4H 2 O, FeCl 3 ·6H 2 O and Co(CH 3 COO) 2 4H 2 O mixed, appropriate addition of distilled water to prepare a solution. Under continuous stirring, add 40% NaOH solution dropwise to the solution until the pH value is 9-12, keep the temperature at 37-47°C, stir and age for 30-60min, magnetically separate and settle, and wash the sediment with deionized water until there is no Cl - Detect, dry, and obtain a magnetic matrix;

[0035] 2) Take CaCl 2 and FeCl 3According to the Ca / Fe molar ratio of 1.5:1 ~ 2.0:1, put it in 100mL deionized water to make a salt solution, add the magnetic matrix prepared above into the above salt solution, and keep the Ca 2+ / Co 2+ The molar ratio is between 25:1 and 40:1. Stir rapidly with a magnetic stirrer in a water bath at 35-45°C for 5 minutes. Then, under...

Embodiment 1

[0044] 1) Synthesis of the catalyst. According to molar ratio Fe 2+ :Co 2+ :Fe 3+ = 1:1:5 ratio FeCl 2 4H 2 O, FeCl 3 ·6H 2 O and Co(CH 3 COO) 2 4H 2 O mixed, appropriate addition of distilled water to prepare a solution. Under constant stirring, add 40% NaOH solution dropwise to the solution until the pH value is 9, keep the temperature at 37°C, stir and age for 30min, magnetically separate and settle, and wash the sediment with deionized water until there is no Cl - Detected, dried to obtain a magnetic matrix; take CaCl 2 and FeCl 3 According to the Ca / Fe molar ratio of 1.5:1, place it in 100mL deionized water, add the magnetic substrate to the above salt solution, and keep the Ca 2+ / Co 2+ The molar ratio is between 25:1. Stir rapidly with a magnetic stirrer in a 35 °C water bath for 5 min. Then, under magnetic stirring, 20 wt% NaOH solution was slowly added to the salt solution until the pH was 9, and the stirring was continued for 30 minutes. The solution ...

Embodiment 2

[0055] 1) Synthesis of the catalyst. According to molar ratio Fe 2+ :Co 2+ :Fe 3+ = 1:1:5 ratio FeCl 2 4H 2 O, FeCl 3 ·6H 2 O and Co(CH 3 COO) 2 4H 2 O mixed, appropriate addition of distilled water to prepare a solution. Under continuous stirring, add 40% NaOH solution dropwise to the solution until the pH value is 9.5, keep the temperature at 39°C, stir and age for 35min, magnetically separate and settle, and wash the sediment with deionized water until it is free of Cl - Detected, dried to obtain a magnetic matrix; take CaCl 2 and FeCl 3 According to the Ca / Fe molar ratio of 1.6:1, place it in 100mL deionized water, add the magnetic matrix to the above salt solution, and keep the Ca 2+ / Co 2+ The molar ratio is between 28:1. Stir rapidly with a magnetic stirrer in a 37 °C water bath for 5 min. Then, under magnetic stirring, 20 wt% NaOH solution was slowly added to the salt solution until the pH was 9.5, and the stirring was continued for 30 minutes. The solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com