Down feather detergent

A detergent and down technology, applied in the field of down detergent, can solve problems such as easy hardening and easy damage to down, and achieve the effects of extending service life, preventing the growth of microorganisms, and strong decontamination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

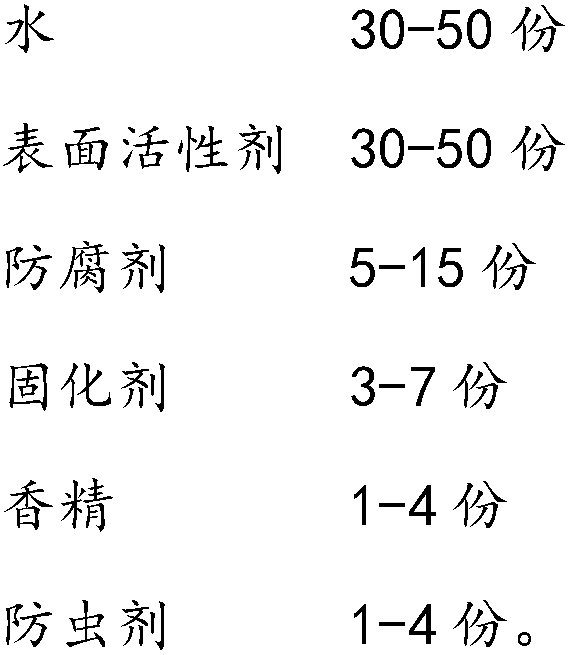

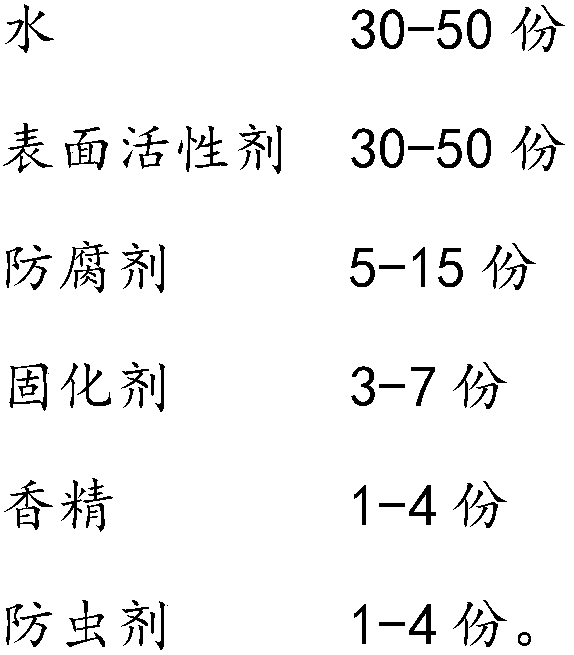

Image

Examples

Embodiment 1

[0029] A kind of down detergent, it is characterized in that, comprises the raw material of following ratio by weight: 30 parts of water, 50 parts of surfactant, 5 parts of antiseptic, 7 parts of curing agent, 4 parts of essence and 4 parts of insect repellent, surface The active agent is one or more of isomeric tridecyl alcohol ether, fatty acid methyl ester ethoxylate, AEO9, ethylene glycol stearate, phosphatidylcholine, and triglyceride, and the preservative is carbamate Pine and paraben, the curing agent is phenolsulfonic acid, magnesium oxide and water-based polyurethane, the insect repellant is camphor balls, the ratio of parts by weight of pine and paraben is 1:2, phenolsulfonic acid, magnesium oxide and The proportion by weight of water-based polyurethane is 1:1:1, including the following steps: 1: Grind the moth balls, filter out the debris with a 1000-mesh screen, 2: add water to the sealed tank, and heat to 60 Celsius, 3: add the mothball powder in step 1 to the wat...

Embodiment 2

[0031] A kind of down detergent, it is characterized in that, comprises the raw material of following proportioning by weight: 40 parts of water, 40 parts of surfactant, 10 parts of preservative, 5 parts of curing agent, 2.5 parts of essence and 2.5 parts of insect repellent, the surface The active agent is one or more of isomeric tridecyl alcohol ether, fatty acid methyl ester ethoxylate, AEO9, ethylene glycol stearate, phosphatidylcholine, and triglyceride, and the preservative is carbamate Pine and paraben, the curing agent is phenolsulfonic acid, magnesium oxide and water-based polyurethane, the insect repellant is camphor balls, the ratio of parts by weight of pine and paraben is 1:2, phenolsulfonic acid, magnesium oxide and The proportion by weight of water-based polyurethane is 1:1:1, including the following steps: 1: Grind the moth balls, filter out the debris with a 1000-mesh screen, 2: add water to the sealed tank, and heat to 70 Celsius, 3: add the mothball powder i...

Embodiment 3

[0033] A down detergent, characterized in that it comprises the following raw materials in parts by weight: 50 parts of water, 30 parts of surfactant, 15 parts of preservative, 3 parts of curing agent, 1 part of essence and 1 part of insect repellent, the surface The active agent is one or more of isomeric tridecyl alcohol ether, fatty acid methyl ester ethoxylate, AEO9, ethylene glycol stearate, phosphatidylcholine, and triglyceride, and the preservative is carbamate Pine and paraben, the curing agent is phenolsulfonic acid, magnesium oxide and water-based polyurethane, the insect repellant is camphor balls, the ratio of parts by weight of pine and paraben is 1:2, phenolsulfonic acid, magnesium oxide and The proportion by weight of water-based polyurethane is 1:1:1, including the following steps: 1: Grind the moth balls, filter out the debris with a 1000-mesh screen, 2: add water to the sealed tank, and heat to 80 Celsius, 3: add the mothball powder in step 1 to the water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com