Sulfur-mould spore carbon ball/phosphate composite material and preparation method and application thereof

A technology of mold spores and composite materials, applied in electrical components, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of easy dissolution and volume change of reaction intermediate products, poor conductivity, accelerated reaction rate, etc., and achieve excellent cycle performance , Improve electrical conductivity, high cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

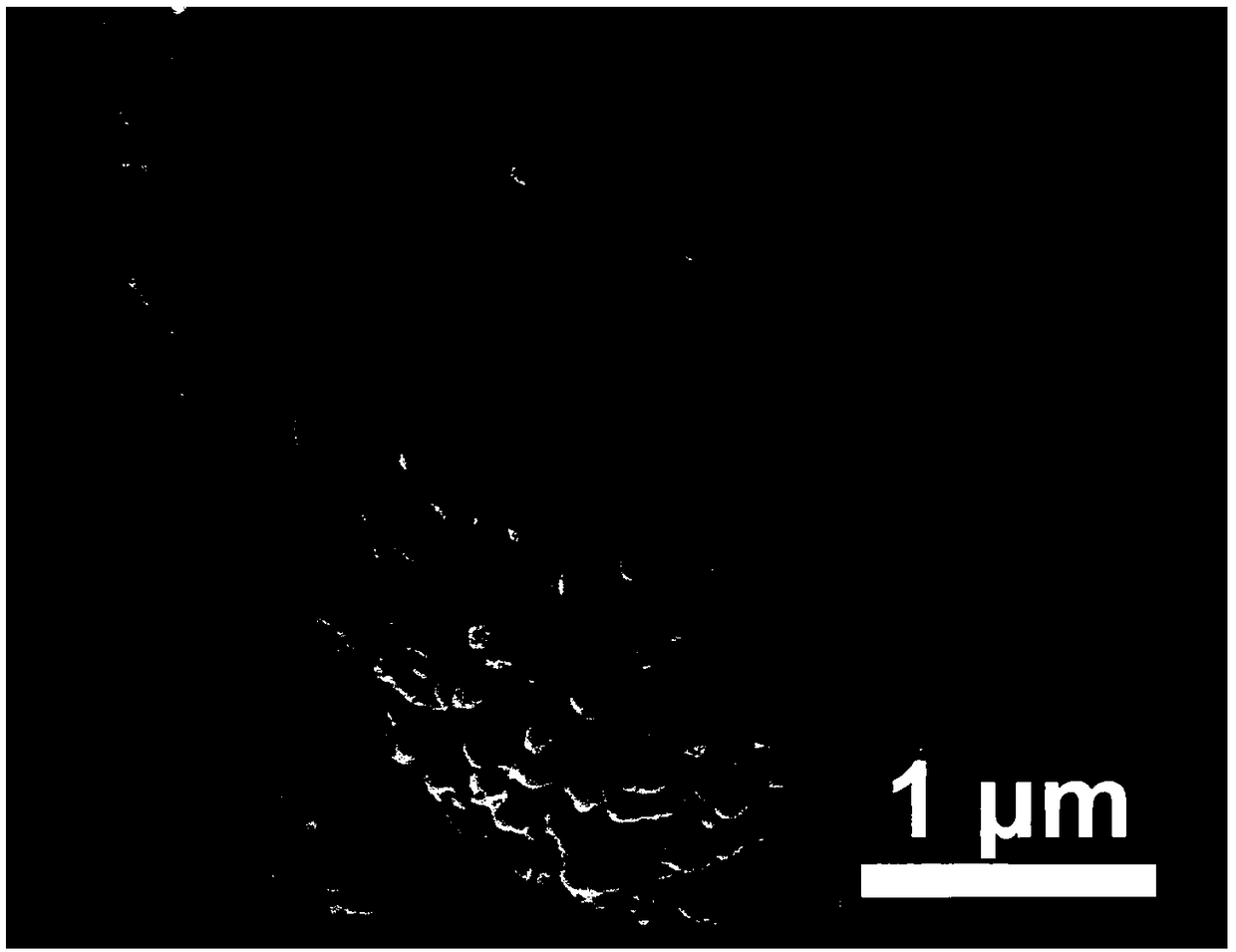

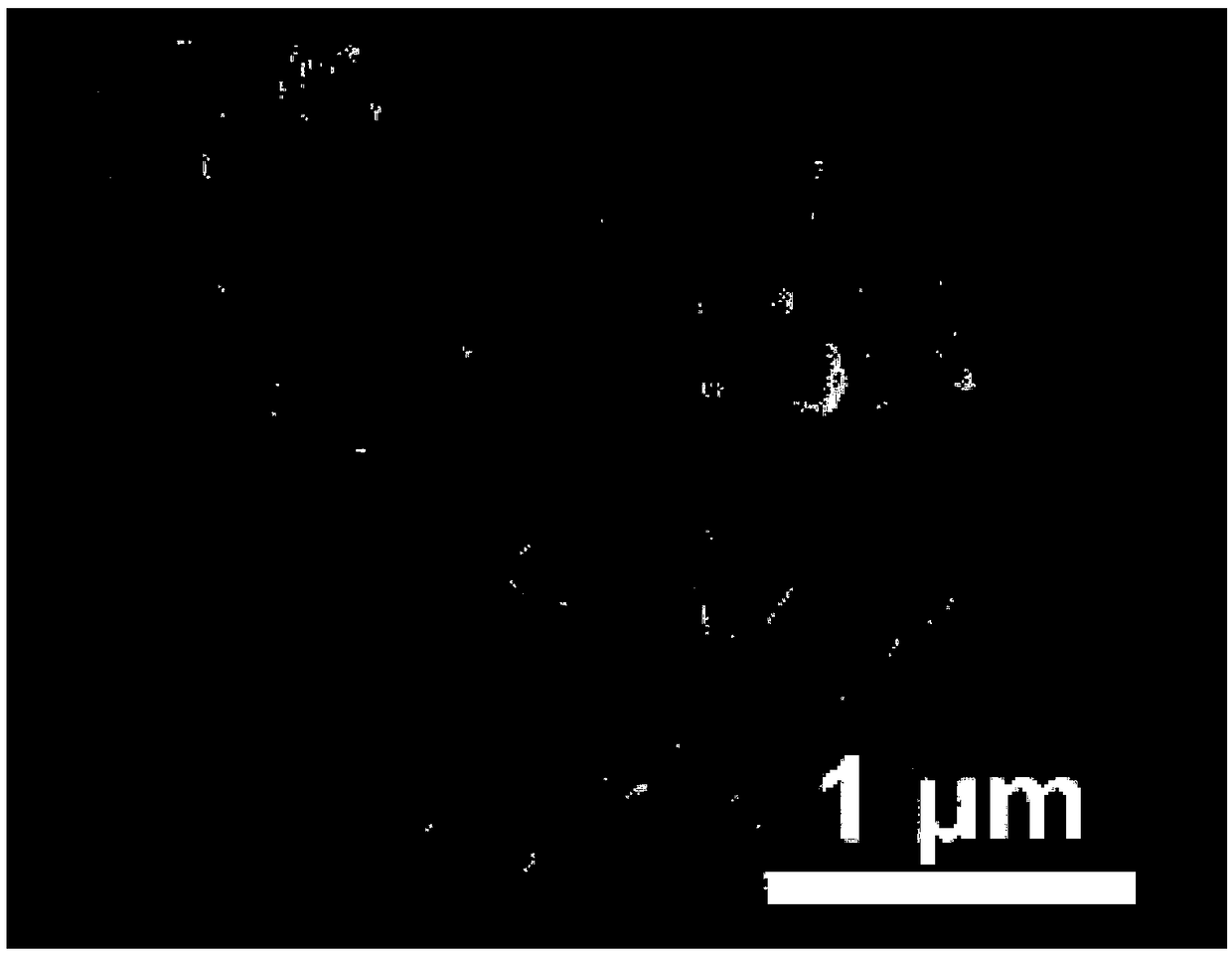

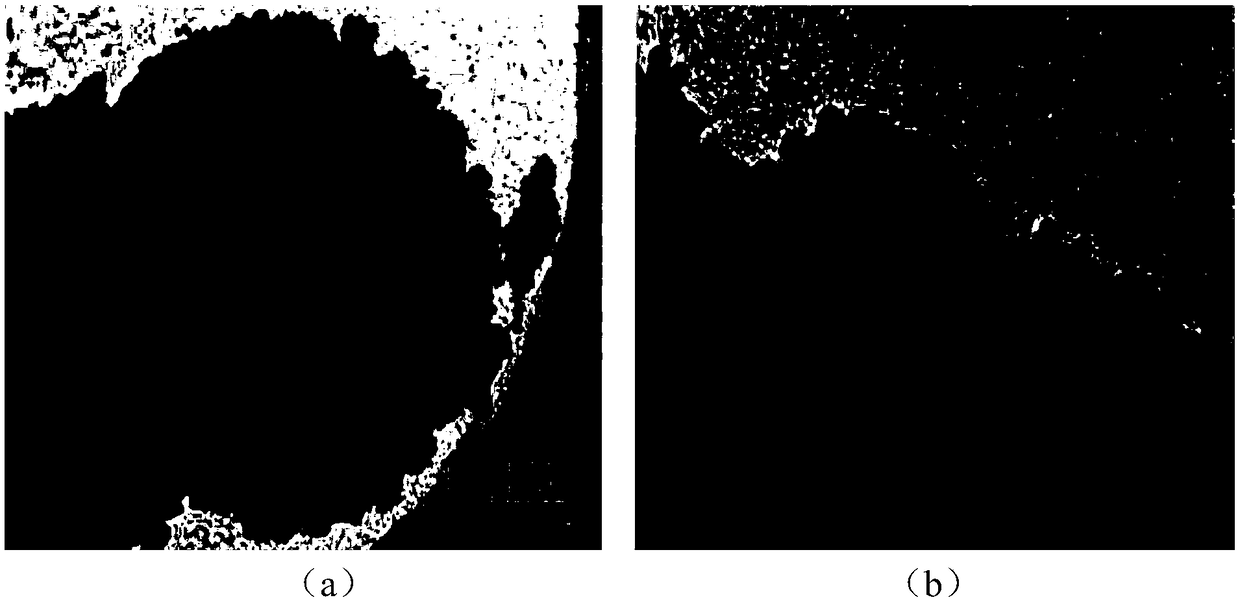

Embodiment 1

[0027] Weigh 500g of rice and cook and cool to room temperature 25°C. The boiled rice is placed in a petri dish, then the inoculation source of 0.1g Aspergillus oryzae (Aspergillus oryzae spore powder as the inoculation source of Aspergillus oryzae, Shandong Changtai Biotechnology Co., Ltd.) is inoculated on its surface, and then transferred to a constant temperature Humidity box, setting temperature is 25 ℃, and setting humidity is 60%, and cultivation time is 10 days, obtains Aspergillus oryzae spore powder 100g after taking out. Weigh 11.88g of nickel chloride hexahydrate and place it in a beaker, add 500ml of deionized water to prepare a 0.1mol / L nickel chloride aqueous solution. Add 100 g of Aspergillus oryzae spore powder into 0.1 mol / L nickel chloride aqueous solution and stir for 45 minutes, then soak for 6 hours, then separate and dry to obtain the mold spore / transition metal nickel chloride composite material. The mold spore / transition metal nickel chloride composit...

Embodiment 2

[0033]Weigh 300g of rice and cook and cool to room temperature 25°C. Cooked rice is placed in the petri dish, then the inoculation source of 0.06g Aspergillus oryzae (aspergillus oryzae spore powder as the inoculation source of aspergillus oryzae, Shandong Changtai Biotechnology Co., Ltd.) is inoculated on its surface, then transferred to a constant temperature Humidity box, setting temperature is 27 ℃, and setting humidity is 65%, and cultivation time is 7 days, obtains Aspergillus oryzae spore powder 60g after taking out. Weigh 7.13g of nickel chloride hexahydrate and place it in a beaker, add 500ml of deionized water to configure a 0.06mol / L nickel chloride aqueous solution. Add 60 g of Aspergillus oryzae spore powder into 0.06 mol / L nickel chloride aqueous solution and stir for 30 minutes, then soak for 12 hours, then separate and dry to obtain the mold spore / transition metal nickel chloride composite material. The mold spore / transition metal chloride composite material w...

Embodiment 3

[0036] Weigh 100g of rice and cook and cool to room temperature 25°C. The boiled rice is placed in a petri dish, then the inoculation source of 0.02g Aspergillus oryzae (aspergillus oryzae spore powder as the inoculation source of aspergillus oryzae, Shandong Changtai Biotechnology Co., Ltd.) is inoculated on its surface, and then transferred to a constant temperature Humidity chamber, setting temperature is 30 ℃, and setting humidity is 70%, and cultivation time is 10 days, obtains Aspergillus oryzae spore powder 20g after taking out. Weigh 2.38g of nickel chloride hexahydrate and place it in a beaker, add 500ml of deionized water to prepare a 0.02mol / L nickel chloride aqueous solution. Add 60 g of Aspergillus oryzae spore powder into 0.02 mol / L nickel chloride aqueous solution and stir for 15 minutes, then soak for 18 hours, then separate and dry to obtain the mold spore / transition metal nickel chloride composite material. The mold spore / transition metal nickel chloride com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com