Silicon-containing alumina carrier and its preparation method and application

A silica alumina, alumina technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor mechanical strength, unsuitable pore structure, etc. Achieve the effect of improving the anti-sintering ability, improving the anti-carbon deposition, and improving the hole expansion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

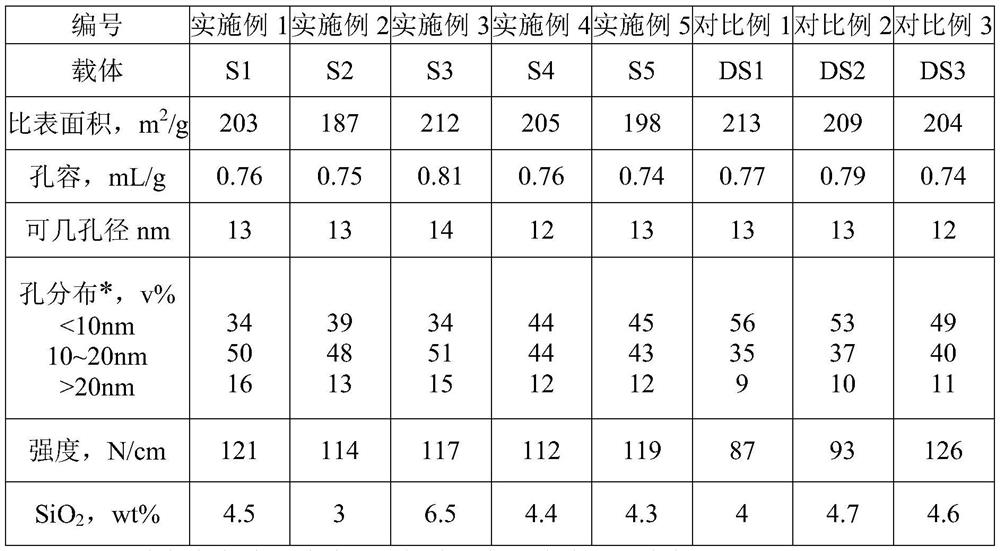

Examples

preparation example Construction

[0021] The preparation method of the silicon-containing alumina carrier provided by the present invention comprises the following steps,

[0022] (1) performing a first contact with the first silicon-containing solution and a first physical pore-enlarging agent, and performing a second contact with the second silicon-containing solution and a second physical pore-enlarging agent;

[0023] (2) Mixing, forming, drying, and roasting the contacted first physical pore-enlarging agent obtained in step (1), the contacted second physical pore-enlarging agent and pseudo-boehmite to obtain a silicon-containing alumina carrier;

[0024] Wherein, both the first silicon-containing solution and the second silicon-containing solution contain silicate, the particle size of the first physical pore-enlarging agent is 100-540 mesh, and the particle size of the second physical pore-enlarging agent is 900-540 mesh. 2000 mesh.

[0025] According to the present invention, the first physical pore-en...

Embodiment 1

[0052] 1) Weigh 15 grams of the first carbon black powder with a particle diameter of 400 meshes and place it in a spray boiling pan, and use a nozzle atomization method to impregnate the first carbon black powder with unsaturated Method: Spray 7.5 mL of ethanol solution of ethyl orthosilicate (amount is 50% of the saturated water absorption of the first carbon black powder, which is equivalent to containing 4 grams of silicon dioxide).

[0053] 2) Weigh 5 grams of the second carbon black powder with a particle diameter of 1300 mesh and place it in a spray boiling pot, and spray the second carbon black powder in a saturated impregnated manner in an atomized manner under the rotating state of 90 rpm. Soak in 5 mL of ethanol solution of ethyl orthosilicate (the amount used is the saturated water absorption of the second carbon black powder, which is equivalent to containing 0.5 g of silicon dioxide).

[0054] 3) the first carbon black powder after the impregnation obtained in th...

Embodiment 2

[0056] Prepare the silicon-containing alumina carrier in the same manner as in Example 1, except that the particle diameter of the first carbon black powder is 325 mesh, and the addition amount is 12.5 grams, and the ethanol solution of 3.8 mL of methyl orthosilicate is used (consumption is the first 30% of the saturated water absorption of a carbon black powder, which is equivalent to containing 2 grams of silicon dioxide) sprays the first carbon black powder. The particle diameter of the second carbon black powder is 1100 meshes, and the add-on is 7.5 grams, uses the ethanol solution of 7.5mL orthosilicate methyl ester (consumption is the saturated water absorption of the second carbon black powder, wherein is equivalent to containing 1 gram of silicon dioxide ) spray the second carbon black powder. The calcination temperature under nitrogen atmosphere is 500°C, and the calcination temperature under air atmosphere is 750°C. The silicon-containing alumina carrier S2 was prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com