Nanofiltration membrane cleaning agent for brine refinement and preparation method thereof

A technology for cleaning agents and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, seawater treatment, etc., can solve problems such as decreased calcium and magnesium rejection rate, decreased desalination rate, and increased desalination rate of membrane elements, achieving high efficiency, Fast sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) In the stirred reactor, add 15 parts of sodium tripolyphosphate, 5 parts of tetrasodium ethylenediaminetetraacetic acid, 5 parts of sodium hexametaphosphate, 0.5 parts of sodium dodecylbenzenesulfonate, and 200 parts of water part, stir well;

[0057] (2) Under normal pressure, control the temperature at 35-40°C, add 30 parts of citric acid, 5 parts of sulfamic acid, 5 parts of oxalic acid and 5 parts of isothiazolinone in sequence, stir and dissolve evenly;

[0058] (3) Continue stirring at normal pressure at a temperature of 35-40° C. During the stirring period, analyze the pH value to 3-4, and stir for 4 hours to obtain a cleaning agent with a pH value of 3.5.

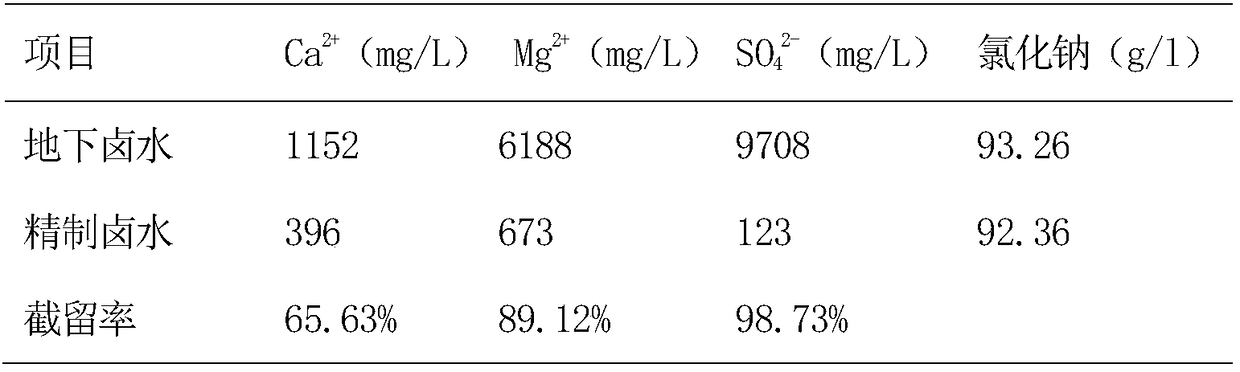

[0059] Apply this agent to clean the bromine-extracting brine nanofiltration membrane system, the effect is as follows:

[0060]

Embodiment 2

[0062] (1) In the reactor with stirring, sequentially add 5 parts of sodium carbonate, 5 parts of sodium citrate, 2 parts of sodium hexametaphosphate, 3 parts of disodium edetate, 0.3 part of sodium lauryl sulfate, 150 parts of water, stir evenly;

[0063] (2) Under normal pressure, control the temperature at 20-25°C, add 10 parts of citric acid, 5 parts of oxalic acid, 5 parts of tartaric acid, 2 parts of 2,2-dibromo-3-nitrilopropionamide in sequence, stir and dissolve evenly;

[0064] (3) Continue stirring under normal pressure at a temperature of 20° C. During the stirring period, analyze the pH value to 4-5, add ammonia water to adjust the pH value, and stir for 3 hours to obtain a cleaning agent with a pH value of 6.

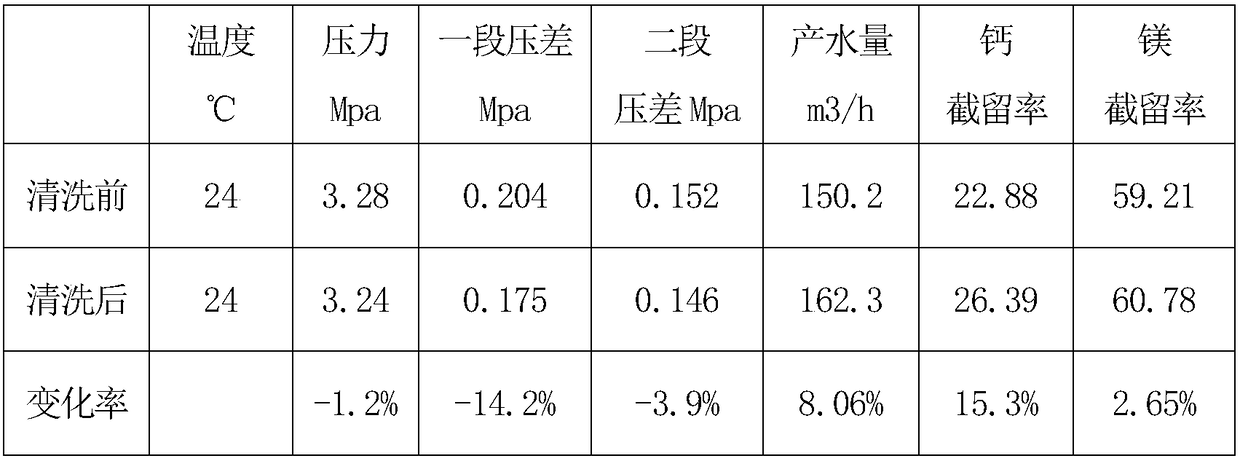

[0065] Apply this agent to clean the bromine-extracting brine nanofiltration membrane system, the effect is as follows:

[0066]

Embodiment 3

[0068] (1) In the stirred reactor, add 5 parts of sodium citrate, 1 part of sodium hexametaphosphate, 1 part of disodium edetate, 0.1 part of sodium lauryl sulfate, and 80 parts of water in sequence, and stir Uniform;

[0069] (2) Under normal pressure, control the temperature at 25-30°C, add 2 parts of sulfamic acid, 2 parts of ammonium citrate, 1 part of malic acid, 2 parts of 2,2-dibromo-3-nitrilopropionamide, Stir to dissolve evenly;

[0070] (3) Continue stirring under normal pressure at a temperature of 25-30° C. During the stirring period, analyze the pH value of 2-3, add citric acid to adjust the pH value, and stir for 2 hours to obtain a cleaning agent with a pH value of 2.

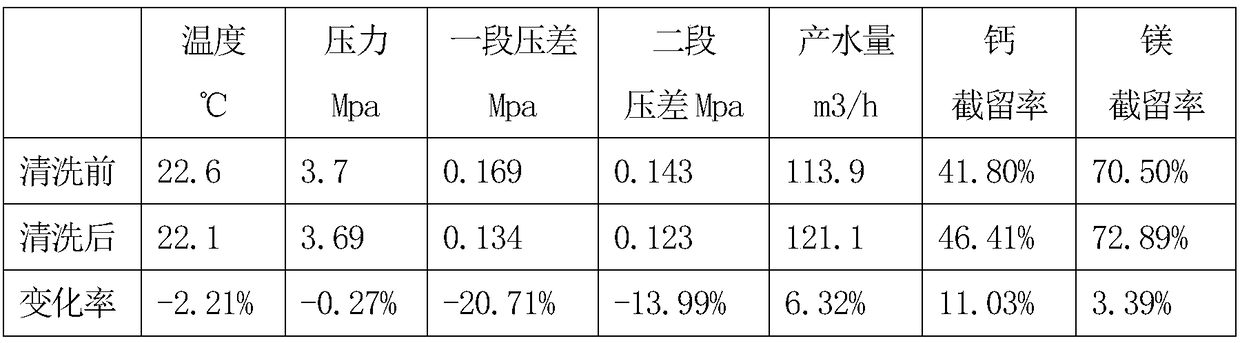

[0071] Apply this agent to clean the bromine-extracting brine nanofiltration membrane system, the effect is as follows:

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com