Preparation method of high-purity vanadium powder

A technology based on high-purity vanadium powder and vanadium pentoxide, which is applied in the field of preparation of high-purity vanadium powder, can solve the problems of harsh reaction conditions, expensive equipment, and high cost, and achieve low cost, easy operation, and low comprehensive energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

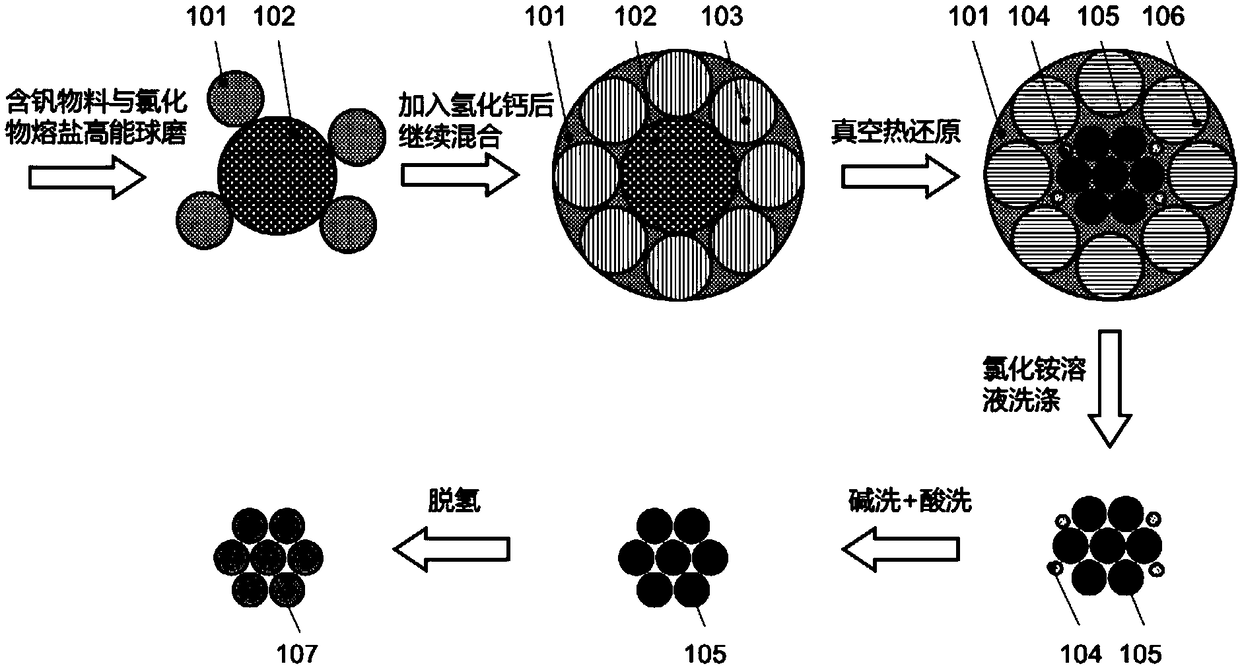

Embodiment 1

[0032] Take 100g of vanadium pentoxide (99.5%) powder and 350g of calcium chloride and sodium chloride (99%) eutectic molten salt, put into a high-energy ball mill and mill for 2 hours, then add 170g of calcium hydride powder (99%) and mix for 0.5h , put it into a vacuum tube furnace for thermal reduction, control the temperature in the furnace to 600°C, and after reduction in an argon atmosphere for 12 hours, perform vacuum thermal reduction to control the vacuum degree to be less than 5 Pa, and the reduction time is 16 hours. The reduced product is in the washing tank Wash with 1mol / L ammonium chloride solution, the temperature of the washing solution is 70°C, and the washing time is 7h. The washed product continues to be washed in the washing tank with 1mol / L sodium hydroxide solution and 1mol / L hydrochloric acid solution for 3 hours, and finally the product is dehydrogenated. The dehydrogenation temperature is 400°C, and then high Pure vanadium powder, its purity is 99.95%...

Embodiment 2

[0034] Take 110g of metavanadic acid (98%) powder and 350g of calcium chloride and sodium chloride (99%) eutectic molten salt, add high-energy ball mill for ball milling for 2h, then add 170g of calcium hydride powder (99%) and mix for 0.5h, Put it into a vacuum tube furnace for thermal reduction, control the temperature in the furnace to 600°C, and after reduction in an argon atmosphere for 12 hours, perform vacuum thermal reduction to control the vacuum degree to be less than 5Pa, and the reduction time is 16 hours. The reduced product is used in the washing tank. Wash in 1mol / L ammonium chloride solution, the temperature of the washing solution is 70°C, and the washing time is 7h. The washed product continues to be washed in the washing tank with 1mol / L sodium hydroxide solution and 1mol / L hydrochloric acid solution for 3 hours, and finally the product is dehydrogenated. The dehydrogenation temperature is 400°C, and then high Pure vanadium powder, its purity is 99.9%. Proc...

Embodiment 3

[0036] Take 100g of vanadium pentoxide (99.5%) powder and 350g of calcium chloride and sodium chloride (99%) eutectic molten salt, put into a high-energy ball mill and mill for 2 hours, then add 170g of calcium hydride powder (99%) and mix for 0.5h , put it into a vacuum tube furnace for thermal reduction, control the temperature in the furnace to 750°C, and after reduction in an argon atmosphere for 12 hours, perform vacuum thermal reduction to control the vacuum degree to be less than 5 Pa, and the reduction time is 16 hours. The reduced product is in the washing tank Wash with 1mol / L ammonium chloride solution, the temperature of the washing solution is 70°C, and the washing time is 7h. The washed product continues to be washed in the washing tank with 1mol / L sodium hydroxide solution and 1mol / L hydrochloric acid solution for 3 hours, and finally the product is dehydrogenated. The dehydrogenation temperature is 400°C, and then high Pure vanadium powder, its purity is 99.99%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com