Ultraviolet ray-curable adhesive agent, cured product, and adhesive sheet

A curing type, adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, polymer adhesive additives, etc., can solve problems such as insufficient low-temperature flexibility and increased glass transition temperature , to achieve the effect of excellent durability, good adhesion and excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

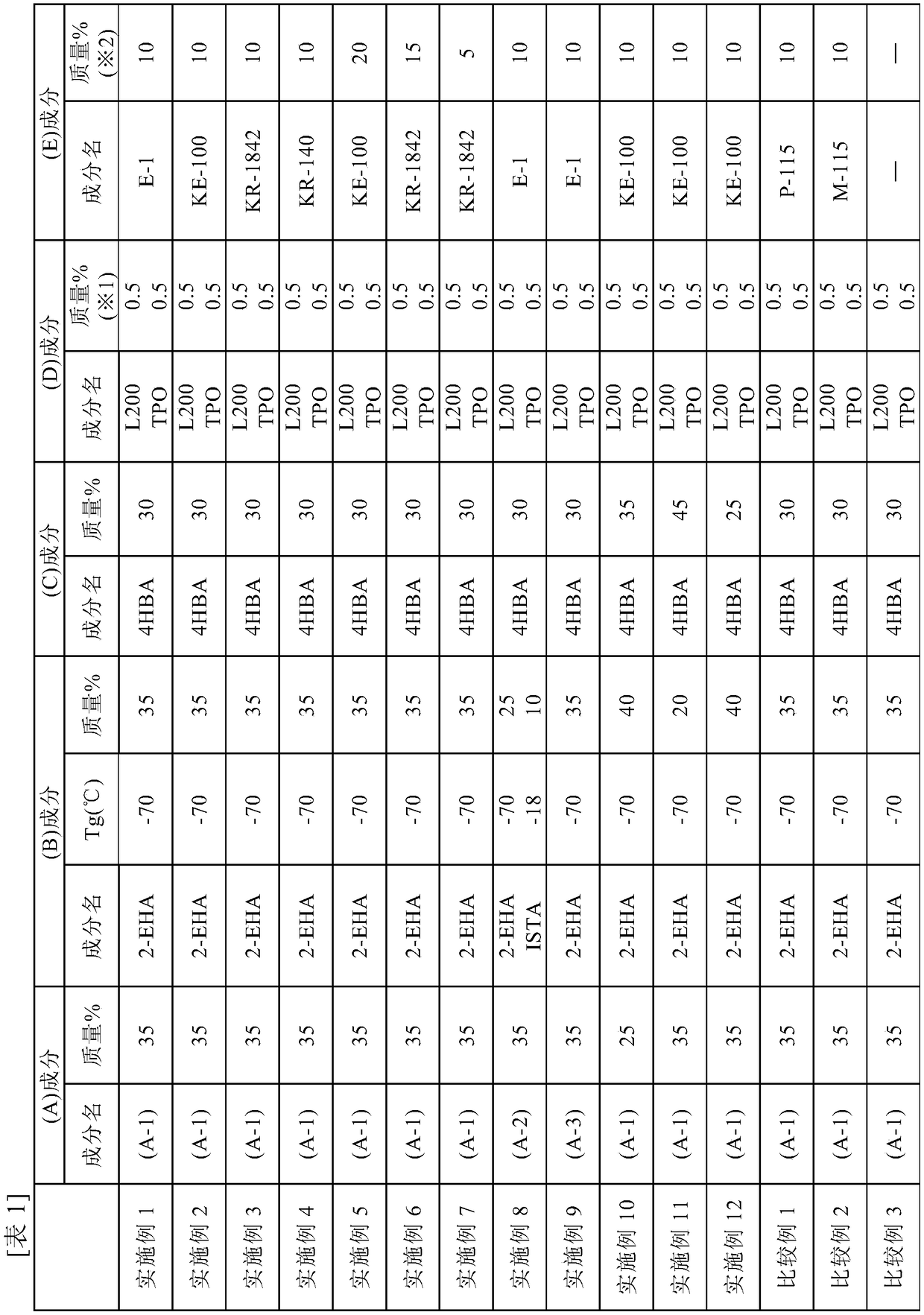

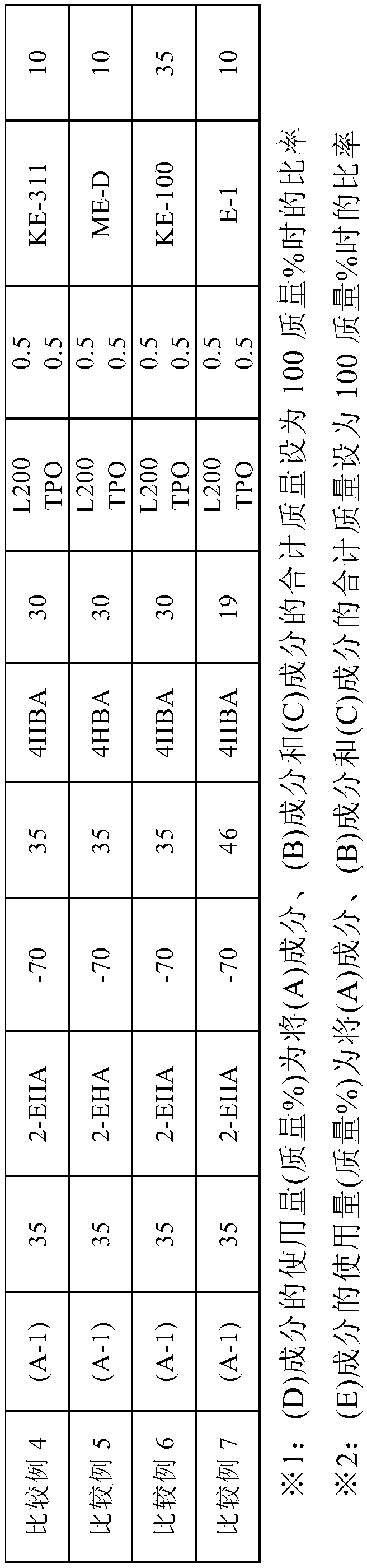

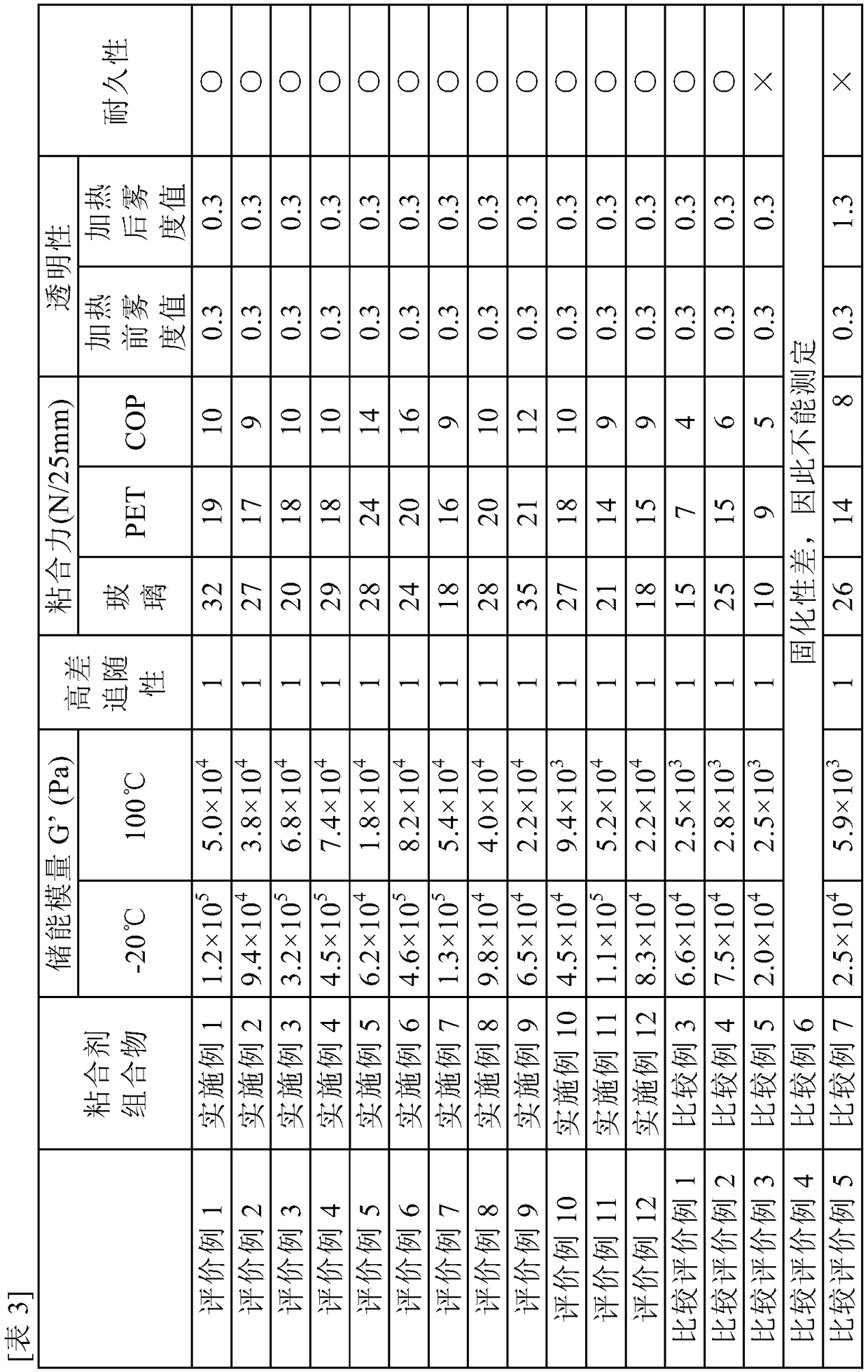

[0097] Hereinafter, the present invention will be specifically described by way of examples and comparative examples. However, it goes without saying that the technical scope of the present invention is not limited by these examples. "Parts" and "%" in the examples are based on mass unless otherwise specified.

[0098] In each manufacture example, the weight average molecular weight of (A) component is the polystyrene conversion value by gel permeation chromatography, and measurement conditions are as follows.

[0099] Measuring device main body: product name "HLC-8220GPC", manufactured by Tosoh Corporation

[0100] Column: product name "TSKGel G1000H", "TSKGel G2000H", both manufactured by Tosoh Corporation

[0101] Developing solvent: tetrahydrofuran

manufacture example 1-1

[0103] 884 parts of polypropylene glycol (manufactured by ADEKA Corporation, trade name "Adeka Polyester P-2000") (hereinafter referred to as PPG2000) with a number average molecular weight of 2000 (hereinafter referred to as PPG2000) was added to a reaction device equipped with a condenser tube, a stirrer, and a nitrogen gas introduction tube. 106 parts of ketone diisocyanate (hereinafter referred to as IPDI), 333 parts of 2-ethylhexyl acrylate (hereinafter referred to as 2-EHA) and 0.4 part of tin octoate, after heating up to 80°C and keeping it warm for 3 hours, the intermediate 2-EHA solution of isocyanate-terminated urethane prepolymer. Next, 10 parts of 4-hydroxybutyl acrylate (hereinafter referred to as 4HBA) was added, and kept at 80°C for 2 hours, and the completion of the reaction was confirmed by NCO measurement, thereby obtaining a weight-average molecular weight of 55,000 and an average value of (meth)acryloyl groups. The 2-EHA solution of the urethane acrylate (h...

manufacture example 1-2

[0105] Add 910 parts of PPG2000, 82 parts of hexamethylene diisocyanate (hereinafter referred to as HDI), 333 parts of 2-EHA and 0.4 parts of tin octoate to the same reaction device as in Manufacturing Example 1-1, and heat up to 80°C and keep it warm for 3 After hours, a 2-EHA solution of the isocyanate-terminated urethane prepolymer was obtained as an intermediate. Next, 8 parts of 2-hydroxyethyl acrylate (hereinafter referred to as HEA) were added, and kept at 80°C for 2 hours, and the completion of the reaction was confirmed by NCO measurement, thereby obtaining a weight-average molecular weight of 57,000 and an average of (meth)acryloyl groups. 2-EHA solution of urethane acrylate (henceforth (A-2) component) whose number is 2.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com