Preparation method and application of silver-loaded viscose fiber

A technology of viscose fiber and viscose fiber, applied in the field of materials, to achieve the effect of firm adsorption, simple experimental process, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: viscose fiber preparation

[0021] (1) Pretreatment of viscose fiber: Ultrasonic immersion of viscose fiber in deionized water for 20-30min, then wrung out the viscose fiber and ultrasonic immersion in ethanol solution for 30min in the same way, and then Dry at 100°C for use.

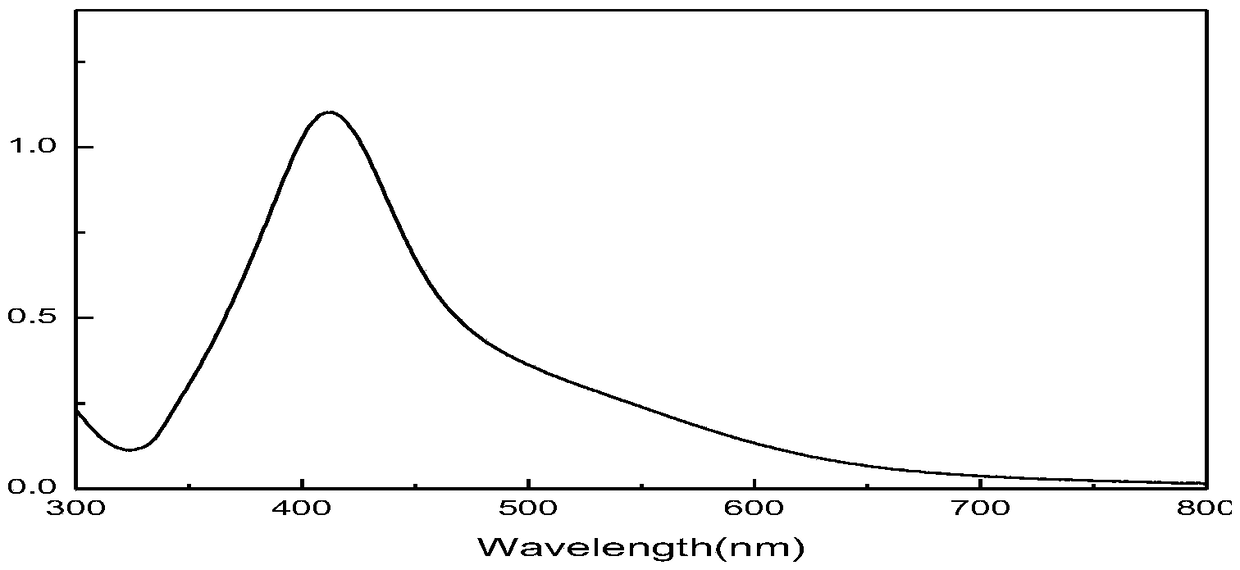

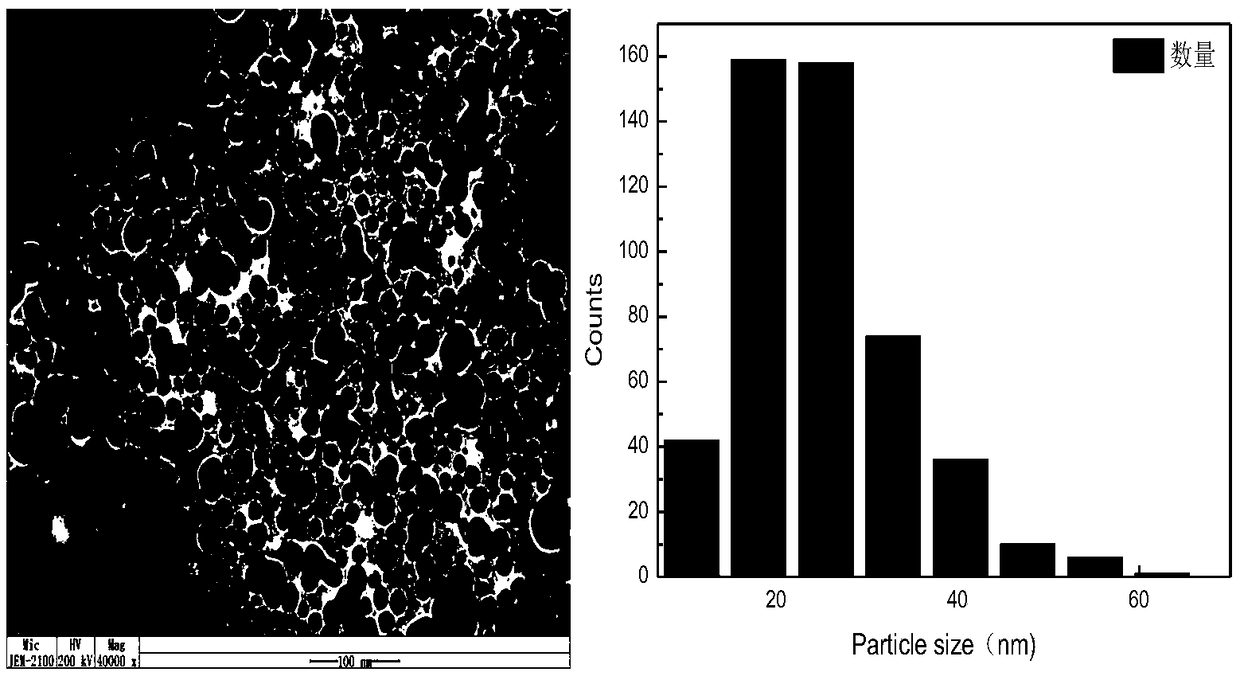

[0022] (2) Preparation of nano-silver sol: at a reaction temperature of 20° C. and a stirring speed of 400 r / min, 1 mL of sodium borohydride solution with a concentration of 10 mM, 3 mL of chitosan solution of 2.5 mM, and 1.25 mM 10 mL of silver nitrate solution was stirred at high speed for 20 min to prepare seed crystals. Then take 2mL of the prepared seed crystal, 10mL of deionized water, 30mL of silver nitrate solution, and 0.5mL of ascorbic acid with a concentration of 10mM to prepare nano-silver sol.

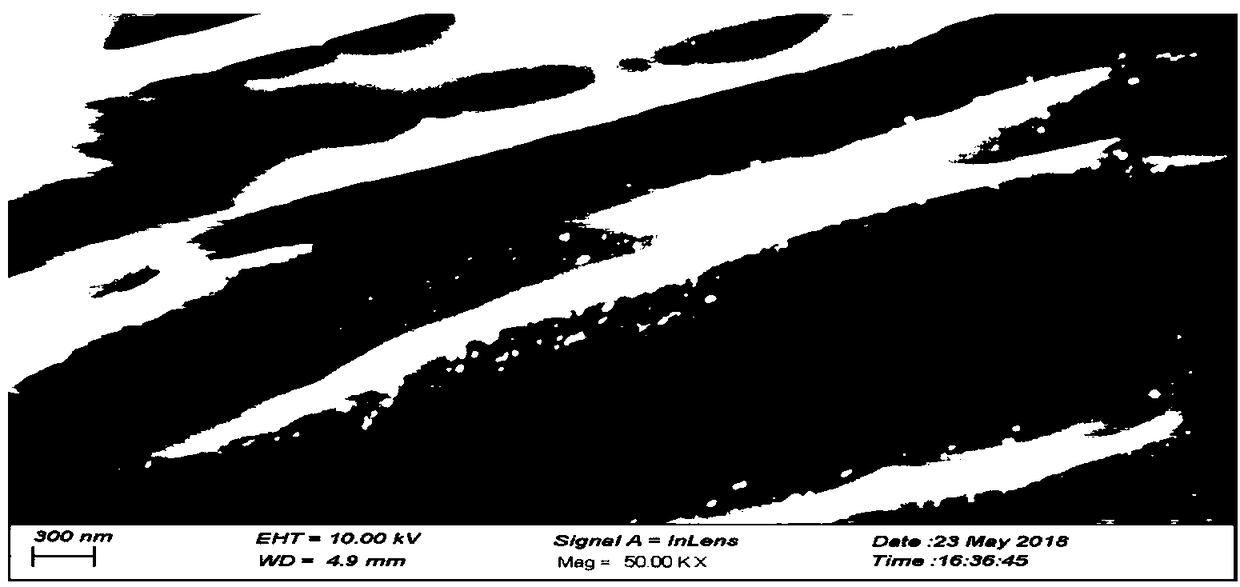

[0023] (3) Preparation of silver-loaded viscose fiber: Viscose fiber and nano-silver sol are taken according to the ratio of mass volume ratio of 1g:40mL to get each raw mater...

Embodiment 2

[0024] Embodiment 2: viscose fiber preparation

[0025] (1) Pretreatment of viscose fiber: ultrasonically immerse the viscose fiber in deionized water for 30 minutes, then wring out the viscose fiber and use the same method to ultrasonically immerse in ethanol solution for 30 minutes, then wring out the viscose fiber at 100 ° C. Dry under favorable conditions for use.

[0026] (2) Preparation of nano-silver sol: at a reaction temperature of 20°C and a stirring speed of 400r / min, 1 mL of sodium borohydride solution with a concentration of 14 mM, 3 mL of chitosan solution of 2.5 mM, 1.25 mM 10 mL of silver nitrate solution was stirred at high speed for 20 min to prepare seed crystals. Then take 2mL of the prepared seed crystal, 10mL of deionized water, 30mL of silver nitrate solution, and 0.05mL of ascorbic acid with a concentration of 10mM to prepare nano-silver sol.

[0027] (3) Preparation of silver-loaded viscose fiber: Viscose fiber and nano-silver sol are taken according...

Embodiment 3

[0028] Embodiment 3: viscose fiber preparation

[0029] (1) Pretreatment of viscose fiber: ultrasonically immerse the viscose fiber in deionized water for 30 minutes, then wring out the viscose fiber and use the same method to ultrasonically immerse in ethanol solution for 30 minutes, then wring out the viscose fiber at 100 ° C. Dry under favorable conditions for use.

[0030] (2) Preparation of nano-silver sol: at a reaction temperature of 20° C. and a stirring speed of 400 r / min, 1 mL of sodium borohydride solution with a concentration of 10 mM, 3 mL of chitosan solution of 2.5 mM, and 1.25 mM 10 mL of silver nitrate solution was stirred at high speed for 20 min to prepare seed crystals. Then get prepared seed crystal 2mL, deionized water 10mL, silver nitrate solution 30mL, concentration is the ascorbic acid 0.5mL reaction preparation nano-silver sol of 10mM;

[0031] (3) Preparation of silver-loaded viscose fiber: Viscose fiber and nano-silver sol are taken according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com