Method for preparing hydrogel having magnetism and temperature synergistic stimulus-responding

A co-stimulation, hydrogel technology, applied in rayon manufacturing, fiber chemical characteristics, fiber types, etc., can solve the problems of slow response rate, single stimulus response, etc., to achieve temperature response rate improvement, simple process, and reduced size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

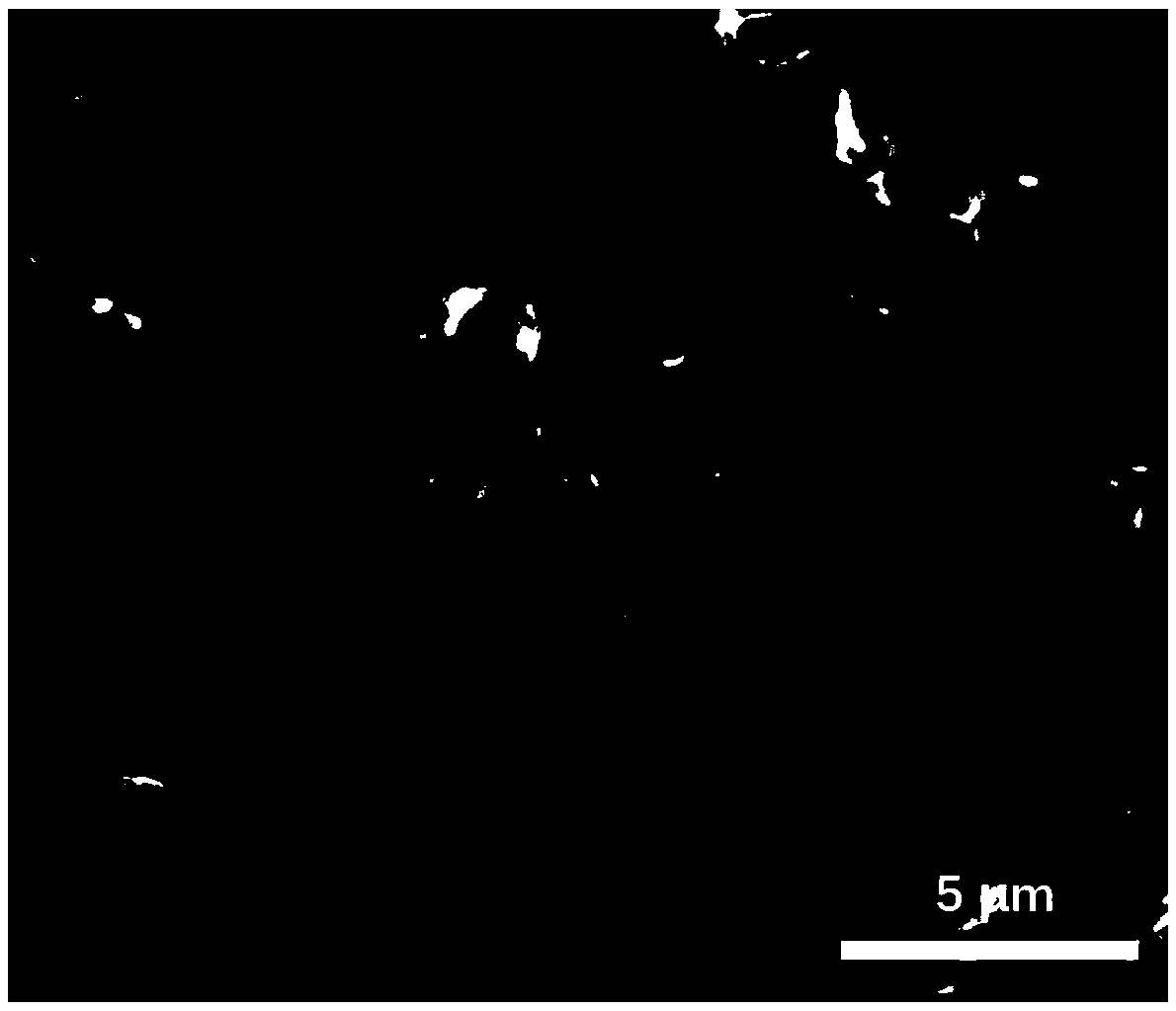

[0035] 1)PU / Fe 3 o 4 Preparation of Magnetic Composite Nanofibers

[0036] 0.1987g FeCl 2 4H 2 O and 0.5404 g FeCl 3 ·6H 2 O was added to 25 g of distilled water, stirred and dissolved by magnetic force at 25°C, then 8 mL of 1 mol / L ammonia water was added, and reacted at 25°C for 3 hours. 3 o 4 Nanoparticles, particle diameter less than 10nm. Add 1g PU into the mixed solvent of 10g DMF and 5g THF, stir magnetically at 60°C for 2h to dissolve completely, and add 0.05g Fe 3 o 4 Nanoparticles are added to the above solution, and stirred by high-speed magnetic force to form a quenching mixed solution. Quenching the quenching mixture in a -40°C refrigerator for 2 hours. After the end, add distilled water to the system to remove DMF and THF. Change the distilled water every 6 hours for 4 times, and finally freeze-dry to obtain PU / Fe 3 o 4 Magnetic composite nanofibers.

[0037] 2) PU-g-PNIPAm / Fe 3 o 4 Preparation of Composite Nanofiber Hydrogels

[0038] Dissolve 1 g...

Embodiment 2

[0043] 1)PU / Fe 3 o 4 Preparation of Magnetic Composite Nanofibers

[0044] 0.1987g FeCl 2 4H 2 O and 0.5404 g FeCl 3 ·6H 2 O was added to 25 g of distilled water, stirred and dissolved by magnetic force at 25°C, then 8 mL of 1 mol / L ammonia water was added, and reacted at 25°C for 4 hours. 3 o 4 Nanoparticles, particle diameter less than 10nm. Add 1g PU into the mixed solvent of 12g DMF and 4g THF, stir magnetically at 60°C for 2h to dissolve completely, and add 0.05g Fe 3 o 4 Nanoparticles are added to the above solution, and stirred by high-speed magnetic force to form a quenching mixed solution. Quenching the quenching mixture in a refrigerator at -30°C for 2 hours. After the end, add distilled water to the system to remove DMF and THF. Change the distilled water every 6 hours for 4 times, and finally freeze-dry to obtain PU / Fe 3 o 4 Magnetic composite nanofibers.

[0045] 2) PU-g-PNIPAm / Fe 3 o 4 Preparation of Composite Nanofiber Hydrogels

[0046] Dissolve ...

Embodiment 3

[0051] 1)PU / Fe 3 o 4 Preparation of Magnetic Composite Nanofibers

[0052] 0.1987g FeCl 2 4H 2 O and 0.5404 g FeCl 3 ·6H 2 O was added to 25 g of distilled water, stirred and dissolved by magnetic force at 25°C, then 8 mL of 1 mol / L ammonia water was added, and reacted at 25°C for 5 hours. 3 o 4 Nanoparticles, particle diameter less than 10nm. Add 1g PU into the mixed solvent of 14g DMF and 3g THF, stir magnetically at 60°C for 2h to make it completely dissolve, and then add 0.08g Fe 3 o 4 Nanoparticles are added to the above solution, and stirred by high-speed magnetic force to form a quenching mixed solution. Quench the quenching mixture in a -30°C refrigerator for 2.5 hours. After the end, add distilled water to the system to remove DMF and THF. Change the distilled water every 6 hours for 4 times, and finally freeze-dry to obtain PU / Fe 3 o 4 Magnetic composite nanofibers.

[0053] 2) PU-g-PNIPAm / Fe 3 o 4 Preparation of Composite Nanofiber Hydrogels

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com