Low-polarity resin and preparation method and application thereof

A low-polarity, resin-based technology, applied in ether preparation, carboxylate preparation, and ester reaction preparation of ether, etc., can solve problems such as gap and limited degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

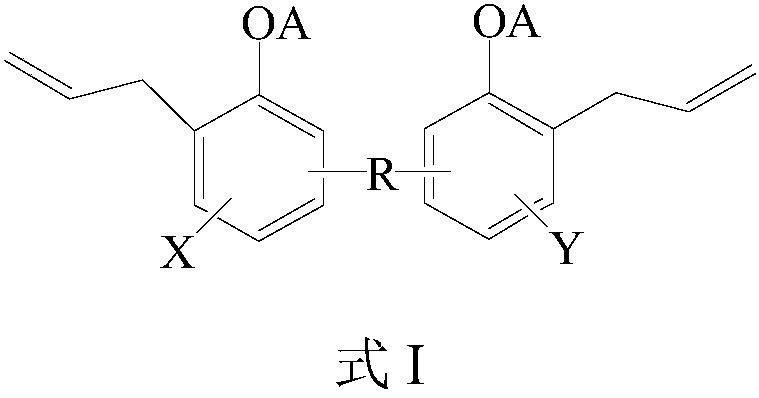

Method used

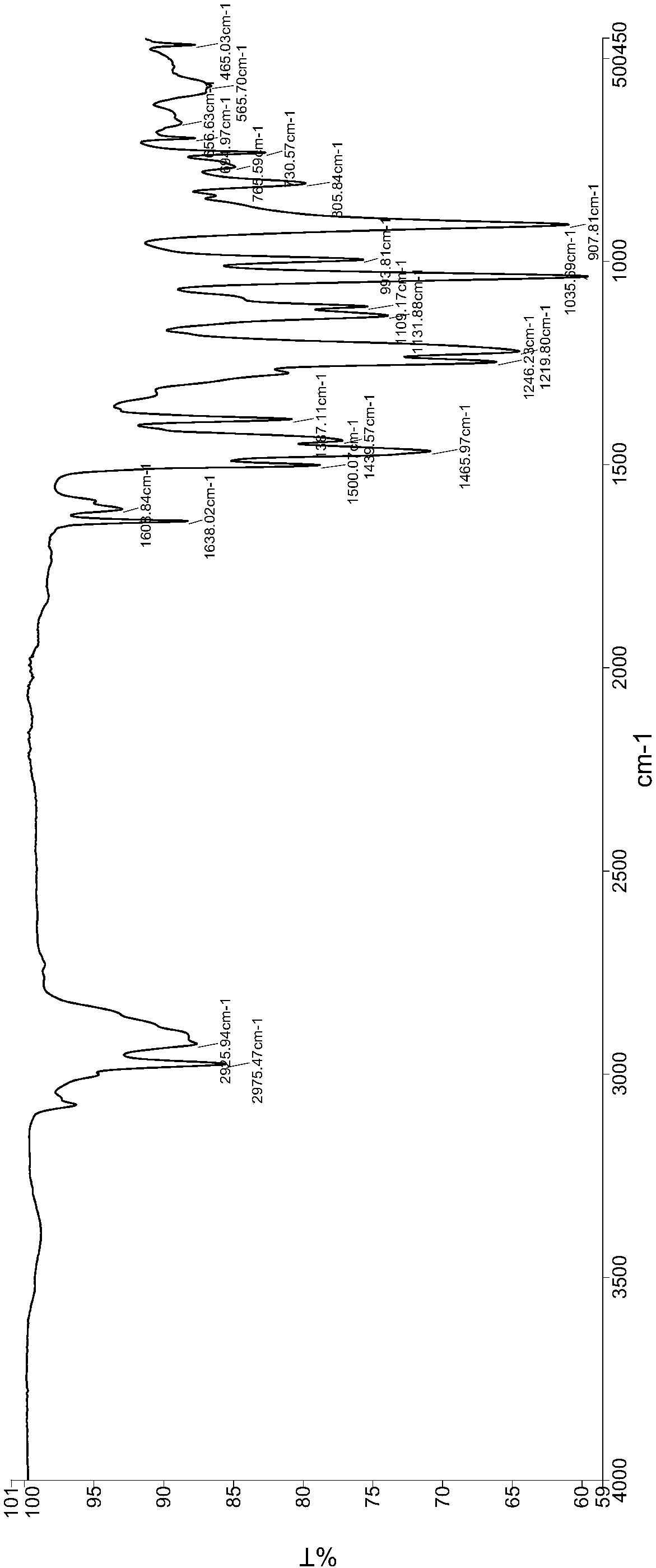

Image

Examples

Embodiment 1

[0073] In this embodiment, the low polarity resin is prepared by the following method, comprising the following steps:

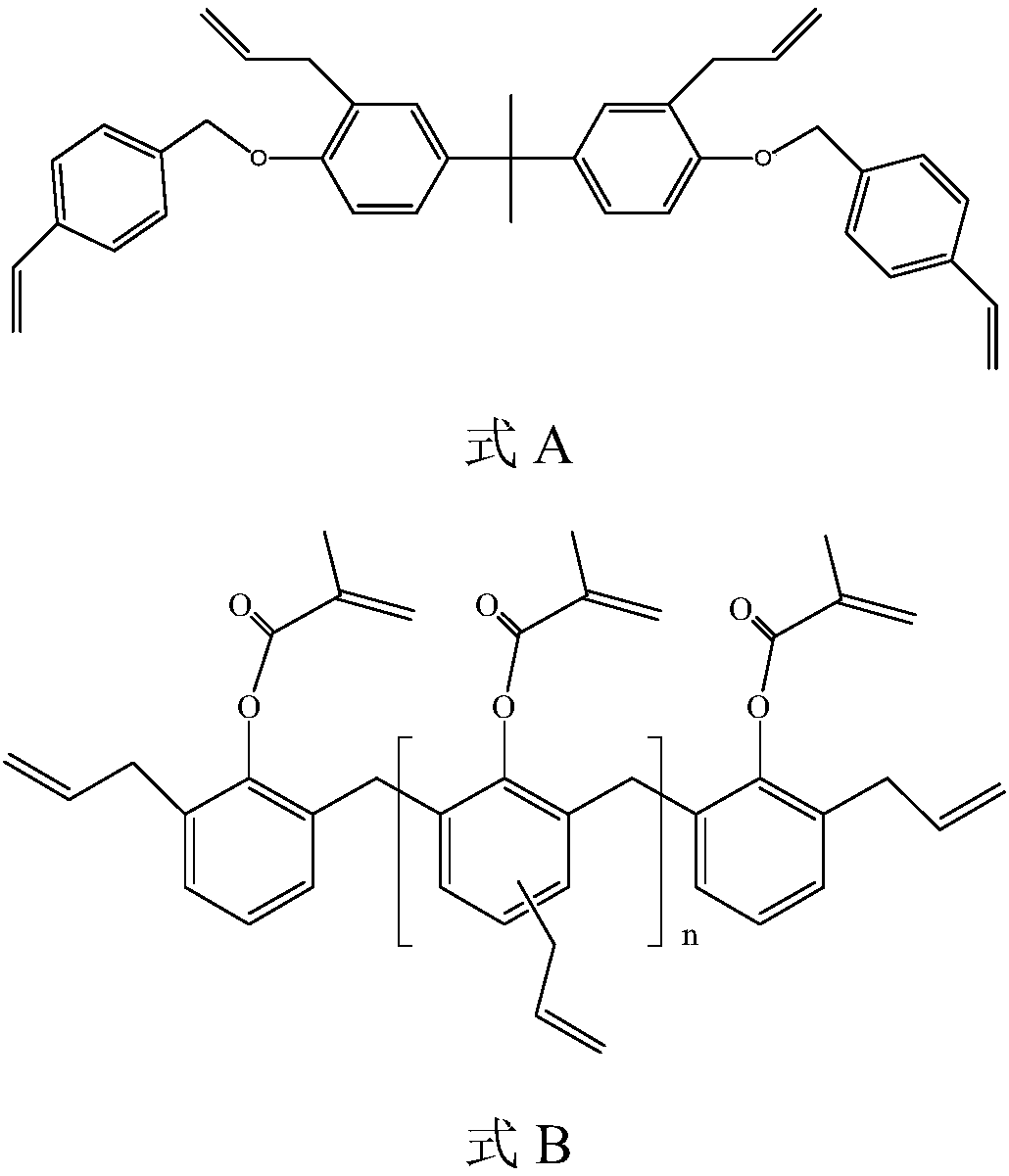

[0074] (1) Add 188g of acetone into the three-necked reaction flask, add 228g of bisphenol A into the reaction flask, stir and dissolve, then add 106g of sodium carbonate. 153g of allyl chloride solution was slowly added dropwise, then the temperature was raised and the reaction was stopped for 4 hours. Filter to remove most of the solvent, wash, and then remove the residual solvent and water to obtain bisphenol A diallyl ether.

[0075] (2) Put 134g of bisphenol A diallyl ether prepared in step (1) into a reaction bottle, heat for rearrangement reaction, cool down and discharge to obtain a brown viscous liquid that is diallyl bisphenol A.

[0076](3) Add 402g of n-butanol in the reaction flask, put 154g of diallyl bisphenol A prepared in step (2) into the reaction flask, stir and dissolve, then add 138g of potassium carbonate. Slowly add 152.5 g of m-viny...

Embodiment 2

[0080] In this embodiment, the low polarity resin is prepared by the following method, comprising the following steps:

[0081] (1) Add 300g of n-butanol into the three-necked reaction flask, add 114g of novolac resin into the reaction flask, stir and dissolve, then add 56g of potassium hydroxide. Slowly add 153g bromopropene solution dropwise, then stop the reaction after heating up for 4 hours. Filter, wash, and remove residual solvent and water to obtain allyl etherified phenolic resin.

[0082] (2) Put 141 g of allyl etherified phenolic resin prepared in step (1) into a reaction bottle, heat for rearrangement reaction, cool down and discharge to obtain brown viscous liquid, namely allylphenolic resin.

[0083] (3) Add 402g n-butanol in the reaction flask, put the 141g allyl phenolic resin prepared by step (2) into the reaction flask, stir and dissolve, then add 102g triethylamine. Slowly add 80g of methacrylic anhydride solution dropwise, then heat up and react for 6 hou...

Embodiment 3

[0086] In this embodiment, the low polarity resin is prepared by the following method, comprising the following steps:

[0087] (1) Add 250g toluene in the three-necked reaction flask, add 118g o-cresol phenolic resin in the reaction flask, after stirring and dissolving, add 100g sodium hydroxide aqueous solution (concentration 40%), then add 1g tetrabutylammonium bromide. Slowly add 153g of allyl chloride solution dropwise, then heat up and react for 4 hours, then stop the reaction, wash, and then remove the solvent to obtain allyl etherified o-cresol novolak resin.

[0088] (2) 159g of allyl etherified o-cresol phenolic resin prepared in step (1) was put into a reaction flask, heated for rearrangement reaction for 4 hours, cooled and discharged to obtain dark brown semi-solid as allyl o-cresol Phenolic phenolic resin.

[0089] (3) 300g of toluene was added in the reaction flask, and 159g of allyl o-cresol phenolic resin prepared in step (2) was put into the reaction flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com