Method for preparing dye adsorbent from waste bricks and application of adsorbent in adsorption of dye contaminants from polluted water

An adsorbent and dye technology, applied in the field of environmental science and engineering, can solve the problems of restricting the effective use of waste bricks, low specific surface area, and limited solid loading capacity, and achieve simple equipment and processes, improved adsorption characteristics, and increased specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

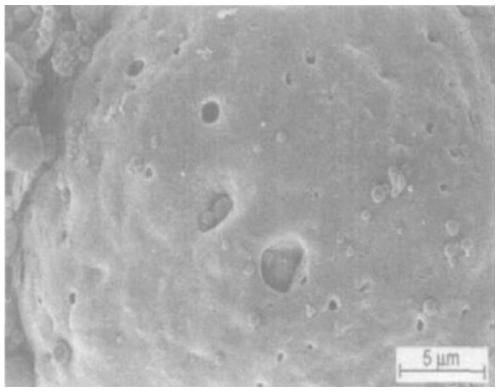

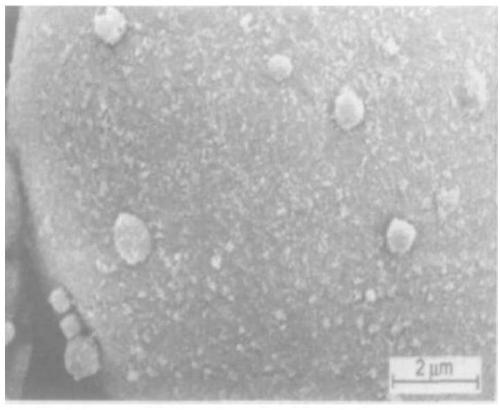

[0026] Mechanically pulverize clay red waste bricks, and sieve powder particles with a particle size of 0.5-1.2 mm to obtain sample A;

[0027] Soak 100g of sample A in 2mol / L sulfuric acid solution for 12h, filter with suction, and wash with water until neutral.

[0028] After drying, it becomes the acid-modified waste brick dye adsorbent.

Embodiment 2

[0030] Clay red waste bricks were mechanically crushed, and the powder particles with a particle size of 0.5-1.2mm were screened to obtain sample A; 100g of sample A was soaked in 2mol / L hydrochloric acid solution for 24h, filtered with suction, washed with water until neutral, and dried at 110 ℃ drying to obtain sample B; sample B was crushed, ground, and sieved to obtain sample C with a particle size of 0.5-1.2 mm. Sample C is the acid-modified waste brick dye adsorbent.

Embodiment 3

[0032] Mechanically pulverize clay red waste bricks, screen out powder particles with a particle size of 0.5-1.2mm, and obtain sample A; soak 100g of sample A in 200ml of 0.5mol / L nitric acid solution for 36h, suction filter, and wash with water until neutral , and dried at 110°C to obtain sample B; sample B was crushed, ground, and sieved to obtain sample C with a particle size of 0.5-1.2 mm. Sample C is the acid-modified waste brick dye adsorbent.

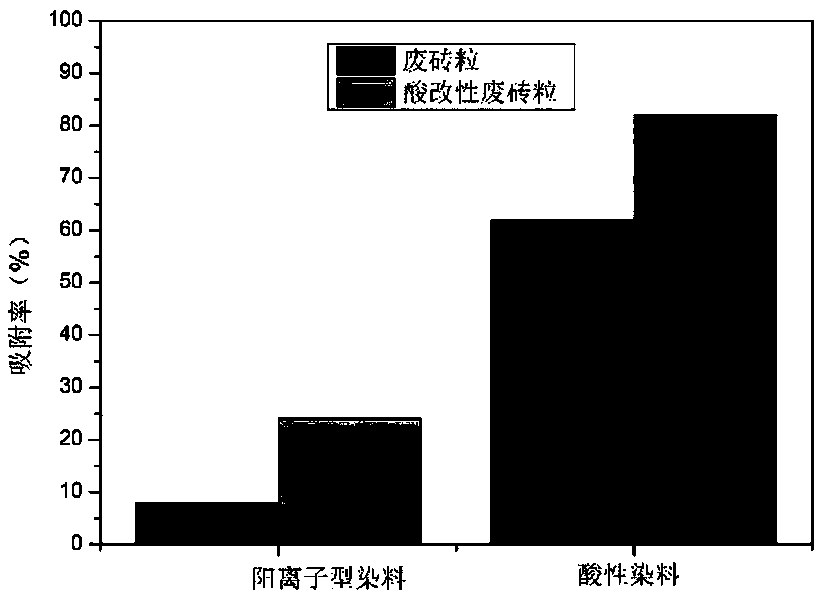

[0033] Effect of Acid Modification of Waste Brick Particles on Adsorption Properties of Cationic and Acid Dyes

[0034] Get the adsorbent 0.3g that sample C obtains among the embodiment 1 and unmodified waste brick grain 0.3g, be placed in the centrifuge tube of the cationic dye (methylene blue) simulated waste water that 25ml mass concentration is 50mg / L respectively in 50ml In addition, get the adsorbent 0.3g obtained in sample C in Example 1 and the unmodified waste brick particles 0.3g, respectively place 50ml of acid dye (T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com