Nano alkali lignin as well as preparation method thereof and application thereof as heavy metal ion catcher

An alkali lignin and nanotechnology, which is applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, chemical instruments and methods, etc. The effect of high efficiency and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

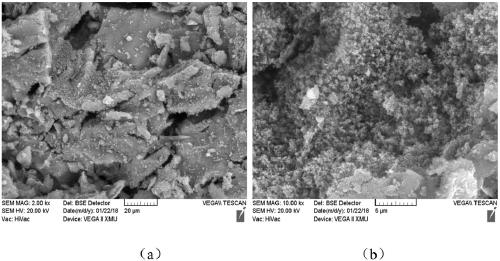

Image

Examples

preparation example Construction

[0028] A preparation method of nano-alkali lignin for purifying heavy metal ions, under the condition of normal temperature and pressure, under the condition of having a freezing device and a magnetic stirrer, comprising the following steps:

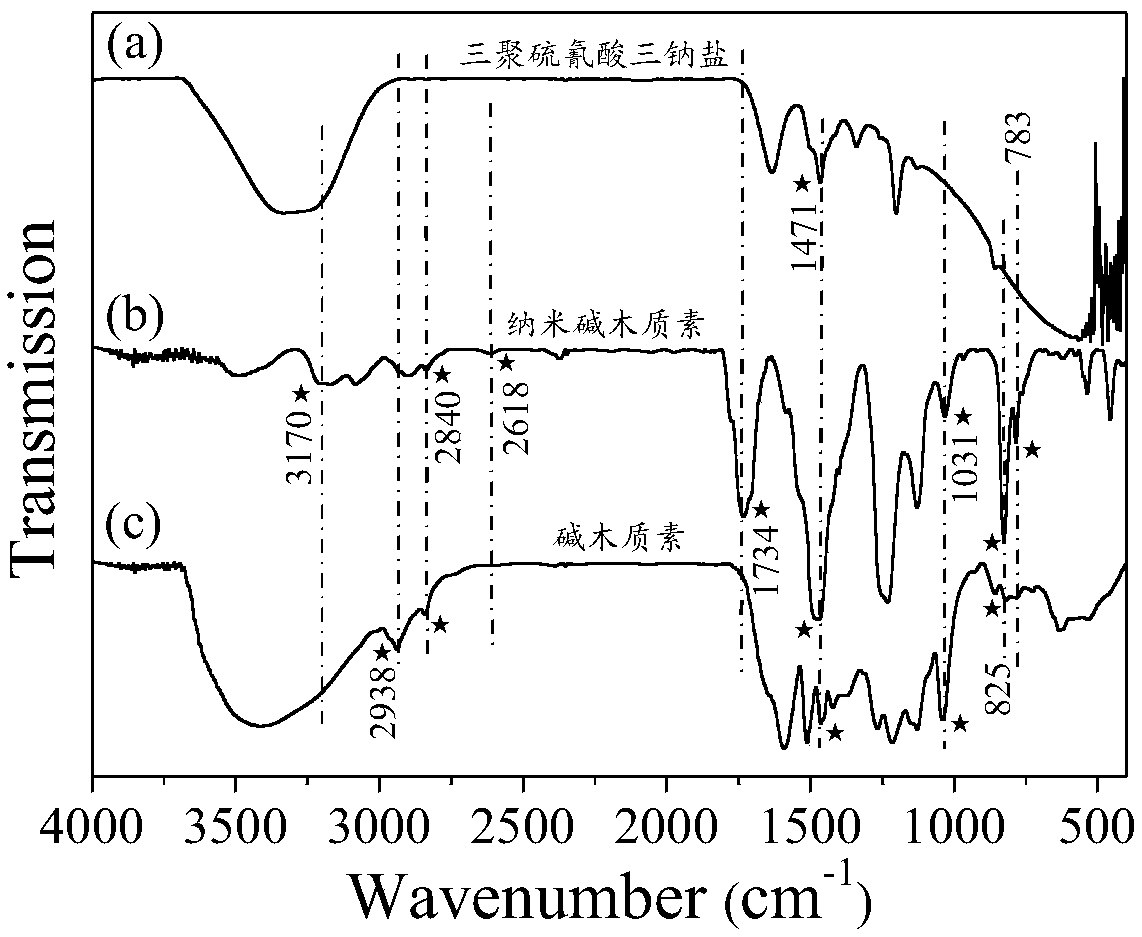

[0029] (1) At room temperature, dissolve 3g of alkali lignin solid in 50ml of water to prepare an aqueous solution, add 15mL of trisodium thiocyanate trisodium salt dropwise to the aqueous solution, and stir the mixed solution with a magnetic stirrer after the addition 1h.

[0030] (2) Use refrigeration equipment to cool down the mixed solution. Below 0°C, add 4g of iodine element and 20g of potassium iodide, control the temperature of the mixed solution at 0°C, and react with magnetic stirring for 2h.

[0031] (3) After the reaction, the solution was suction filtered, washed several times with deionized water, 50 mL of hydrochloric acid solution was added, and the mixed solution was stirred at room temperature for 3 h.

[0032] (4) Suc...

Embodiment 2

[0037] A preparation method for purifying the nano-alkali lignin of heavy metal ions, comprising the following steps:

[0038] (1) At room temperature, 5 g of solid alkali lignin was dissolved in 45 ml of water to prepare an aqueous solution, 10 mL of trisodium thiocyanate solution was added dropwise to the aqueous solution, and the mixed solution was magnetically stirred for 2 hours.

[0039] (2) Use refrigeration equipment to cool down the mixed solution. Below 0°C, add 3g of iodine element and 15g of potassium iodide, control the temperature of the mixed solution at 0°C, and stir magnetically for 2h.

[0040] (3) After the reaction, the solution was suction filtered, washed several times with deionized water, 60 mL of sulfuric acid solution was added, and the mixed solution was stirred at room temperature for 3 h.

[0041] (4) Filtrate again, wash repeatedly with deionized water, use vacuum freeze-drying to obtain gray solid powder, the structural characteristics and functi...

Embodiment 3

[0045] A preparation method of nano-alkali lignin for purifying heavy metal ions, characterized in that it comprises the following steps:

[0046] (1) At room temperature, dissolve 6g of alkali lignin solids in 60ml of water to prepare an aqueous solution, add 15mL of trisodium thiocyanate trisodium salt dropwise to the water solution, and mix the solution with a magnetic stirrer after the addition. Stir for 1h.

[0047] (2) Use refrigeration equipment to cool down the mixed solution. Below 0° C., add 5 g of iodine element and 10 g of potassium iodide, control the temperature of the mixed solution at 0° C., and react with magnetic stirring for 2 hours.

[0048] (3) After the reaction, the solution was suction filtered, washed several times with deionized water, 70 mL of hydrochloric acid solution was added, and the mixed solution was stirred at room temperature for 3 h.

[0049] (4) Suction filtration again, repeated washing with deionized water several times, and vacuum free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com