Diatomite-based composite material and preparation method thereof

A composite material and diatomite technology, applied in the field of photocatalysis, can solve the problems such as the catalytic purification effect of diatomite photocatalyst can not meet the requirements, etc., and achieve the effect of excellent photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

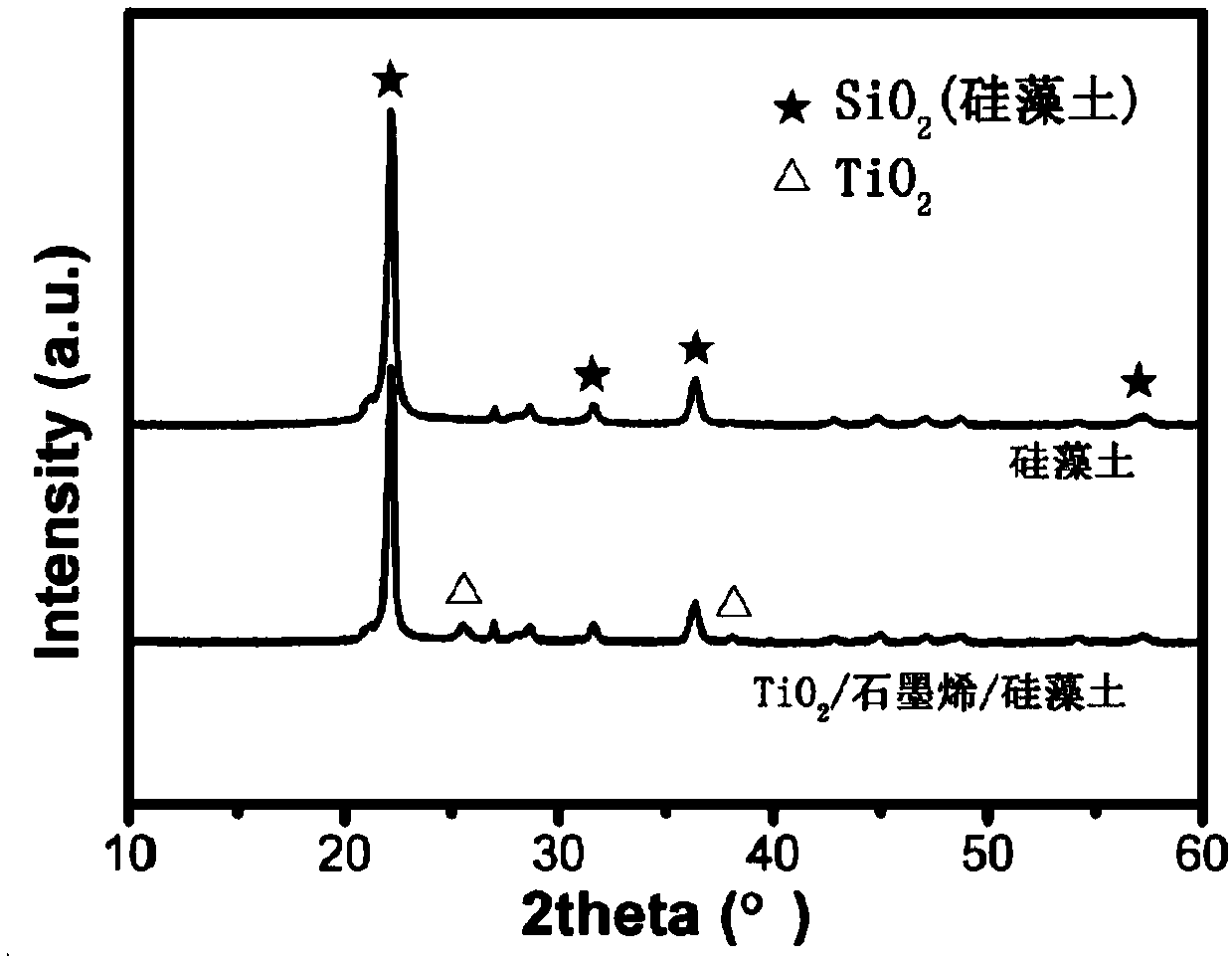

[0047] The present invention also provides a method for preparing the diatomite-based composite material described in the above technical solution, comprising the following steps:

[0048] a) depositing and growing graphene on diatomite by chemical vapor deposition to obtain a graphene-diatomite composite;

[0049] b) hydrothermally reacting the graphene-diatomite composite with a titanium source compound and a bismuth source compound to obtain a diatomite-based composite material.

[0050] According to the present invention, the graphene is deposited and grown on the diatomite by chemical vapor deposition to obtain the graphene-diatomite composite.

[0051] Wherein, the type, source, and dosage ratio of diatomite to graphene are consistent with those described in the above technical solution, and will not be repeated here.

[0052] In the present invention, the diatomite is preferably purified before chemical vapor deposition. The purification operation, condition parameter...

Embodiment 1

[0064] 1.1 Sample preparation

[0065] Get 5g diatomaceous earth and add in the there-necked flask that contains 50mL deionized water under magnetic stirring condition, then dropwise add 50g sulfuric acid solution (concentration is 40wt%), be placed in oil bath then, at 100 ℃, magnetic stirring reaction After 4 hours, 75 mL of deionized water was added, and the reaction was continued for 1 hour to obtain acid-treated diatomite. The resulting acid-treated diatomite was filtered and washed with deionized water until the pH was 7, then placed in a tube furnace and calcined at 450°C for 3 hours to obtain a white solid powder, which was pure diatomite.

[0066] In a tube furnace, 0.7g of pure diatomite was heated from room temperature to 1000°C under argon and hydrogen conditions, and after heating for 87 minutes, methane gas was introduced (the volume ratio of argon, hydrogen and methane was 100:10 : 1), diatomite was reacted at 1000° C. for 1 hour, then the supply of methane and...

Embodiment 2

[0086] Diatomite, the composite material obtained in Example 1, the composite material obtained in Comparative Example 1, and the composite material obtained in Comparative Example 2 were tested for photocatalytic activity, as follows:

[0087] Weigh 0.10g of samples respectively and place them in a beaker, add 30mL of deionized water, ultrasonically disperse for 5min, then transfer to a glass disc with a diameter of 12cm (place two in parallel when measuring the activity), and dry at 60°C for later use. The above-mentioned samples loaded in glass discs were placed in a continuous flow reactor to determine the photocatalytic purification of NO x performance.

[0088] The specific test process is as follows:

[0089] Place the glass disc loaded with the sample in a 5.4L cuboid (30cm×15cm×12cm) photocatalytic reactor, cover the upper surface of the reactor with quartz glass to seal, place a 150W metal halide lamp above the quartz glass, and install an ultraviolet light under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com