High temperature oxidation-resistant graphite ceramic composite material and preparation method thereof

A ceramic composite material, high temperature anti-oxidation technology, applied in the field of inorganic non-metallic material forming, can solve problems such as lack of process methods, and achieve the effect of ensuring adhesion performance, good high-temperature oxidation resistance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

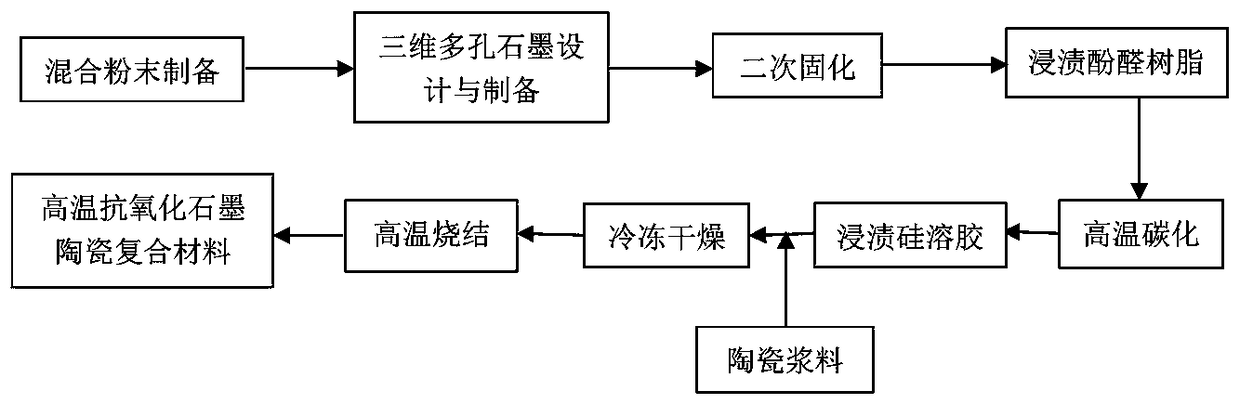

[0040] The specific preparation steps of embodiment 1 are as follows:

[0041] (1) Preparation of mixed powder

[0042] Natural flake graphite (carbon content greater than 95%, 150-270 mesh), thermosetting phenolic resin powder (500 mesh), high-purity silicon powder (chemical purity 99%, 200 mesh) and boron carbide powder (chemical purity 99 %, 200 mesh) according to the mass ratio of 41:25:24:10 and mix evenly.

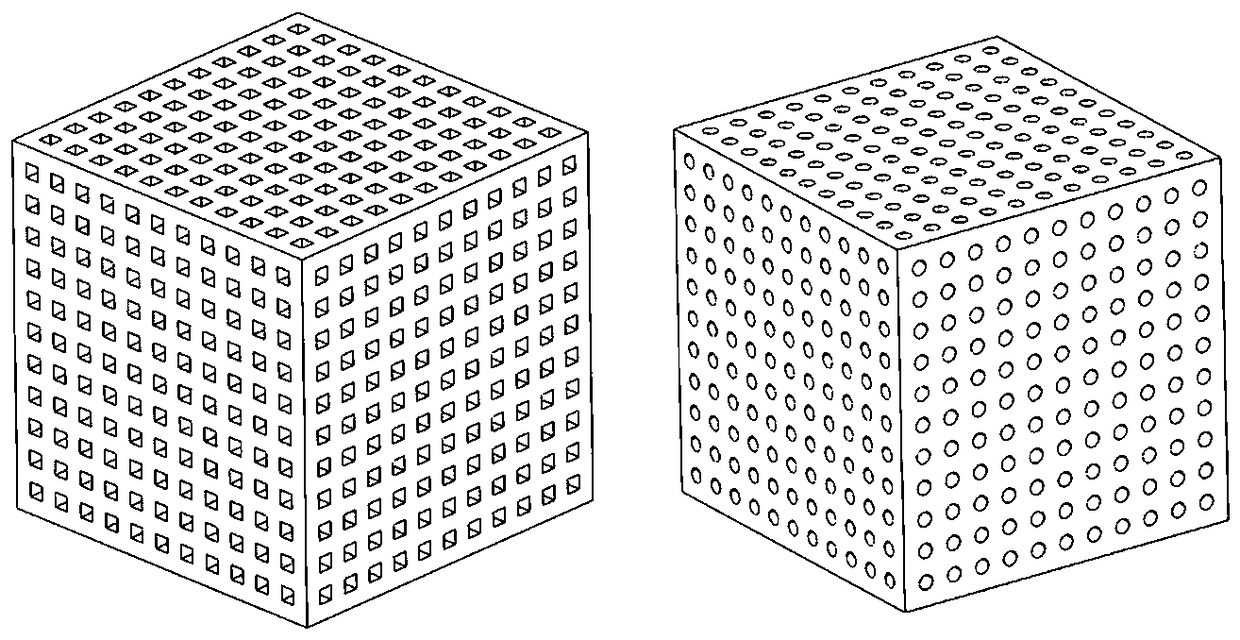

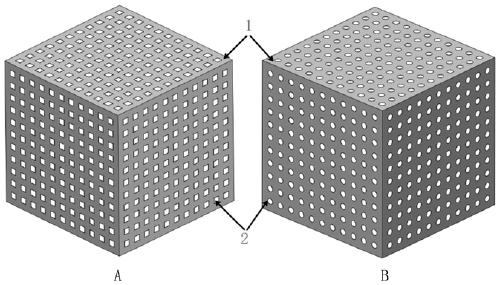

[0043] (2) Design and preparation of three-dimensional porous graphite

[0044] According to the uniform arrangement and distribution, the maximum characteristic size of the square hole is 8mm to design the graphite green body, and the selective laser powder sintering forming technology is adopted according to the layer thickness of 0.1mm, the filling distance of 0.1mm, the filling speed of 1500mm / s, the filling power of 17w, and the contour speed of 1000mm / s, profile power 10w, preheating temperature 40°C process parameters to quickly prepare three-dimensional po...

Embodiment 2

[0052] Embodiment 2 concrete preparation steps are as follows:

[0053] (1) Preparation of mixed powder

[0054] Natural flake graphite (carbon content greater than 95%, 150-270 mesh), thermosetting phenolic resin powder (500 mesh), high-purity silicon powder (chemical purity 99%, 200 mesh) and boron carbide powder (chemical purity 99 %, 200 mesh) according to the mass ratio of 46:25:24:5 and mix evenly.

[0055] (2) Design and preparation of three-dimensional porous graphite

[0056] According to the uniform arrangement and distribution, the maximum characteristic size of circular holes is 4mm, and the graphite green body is designed, and the selective laser powder sintering forming technology is adopted according to the layer thickness of 0.1mm, the filling distance of 0.2mm, the filling speed of 1500mm / s, the filling power of 20w, and the contour speed of 800mm. / s, profile power 10w, and preheating temperature 40°C process parameters to quickly prepare three-dimensional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com