High-temperature antioxidant coating formed on matrix material and preparation method thereof

A high-temperature anti-oxidation and matrix material technology, which is applied in the field of protective coating preparation, can solve the problems of powder high-temperature oxidation deposition rate and other problems, and achieve the effects of excellent high-temperature anti-oxidation ability, thermal stress relief, and excellent high-temperature anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

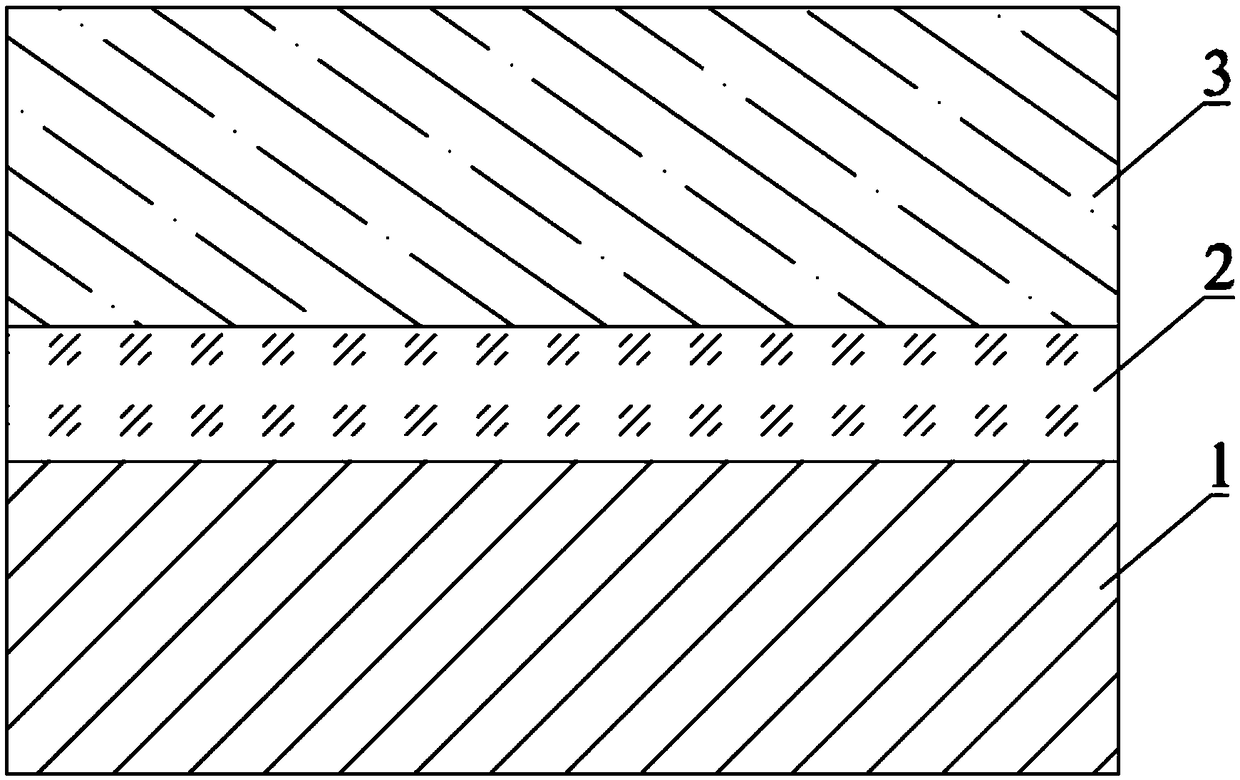

[0036] In a second aspect, the present invention provides a method for preparing the high-temperature oxidation-resistant coating described in the first aspect of the present invention, said method comprising the steps of:

[0037] (1) Put silicon carbide powder and tetratantalum hafnium pentacarbide powder into the powder feeder of the low-pressure plasma spraying equipment respectively and carry out drying treatment;

[0038] (2) fixing the composite material on a turntable in the vacuum chamber of the low-pressure plasma spraying equipment; and

[0039] (3) The silicon carbide layer and the mixed layer are sequentially prepared on the surface of the composite material by a low-pressure plasma spraying method, thereby preparing the high-temperature oxidation-resistant coating on the surface of the composite material.

[0040] In the prior art, the atmospheric plasma spraying method is used to prepare the anti-oxidation coating, but the jet flow of the atmospheric plasma spra...

Embodiment 1

[0061] ① Preparation C f / C-SiC ceramic matrix composite material matrix original piece, the size is Φ25×4mm, the surface is polished on 400#, 800#, 1200# sandpaper respectively, put into acetone and ultrasonically cleaned for 10min before use.

[0062] ②Select SiC and Ta after spray granulation 4 HfC 5 Powder, the particle size of SiC powder is 5-30μm, the fluidity is 210s / 50g, Ta 4 HfC 5 The particle size of the powder is 10-40 μm, and the fluidity is 10s / 50g. The powder particles after granulation are hollow spherical powders composed of nano-sized particles; add the above powders to the powder feeder of the low-pressure plasma spraying equipment, and heat up to 60°C Afterwards, heat-preserve and dry for 4 hours.

[0063] ③The silicon carbide layer was prepared on the substrate by low-pressure plasma spraying method: the pretreated C f / C-SiC ceramic matrix composite material matrix is installed on the automatic workpiece rotating table in the vacuum chamber, and the...

Embodiment 2

[0068] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0069] In ④, after the jet is stabilized, open the 4 HfC 5 The powder feeder, the powder feeding rate is 3.3g / min and 80g / min respectively, the deposition time is 1min, and the first five tantalum hafnium carbide-silicon carbide layers are obtained; then adjust SiC and Ta 4 HfC 5 The powder feeding rates were 1g / min and 95g / min, respectively, and then deposited for 1min to obtain the second tantalum hafnium carbide-silicon carbide layer, thus obtaining a Ta with a total thickness of 219μm. 4 HfC 5 -SiC gradient layer.

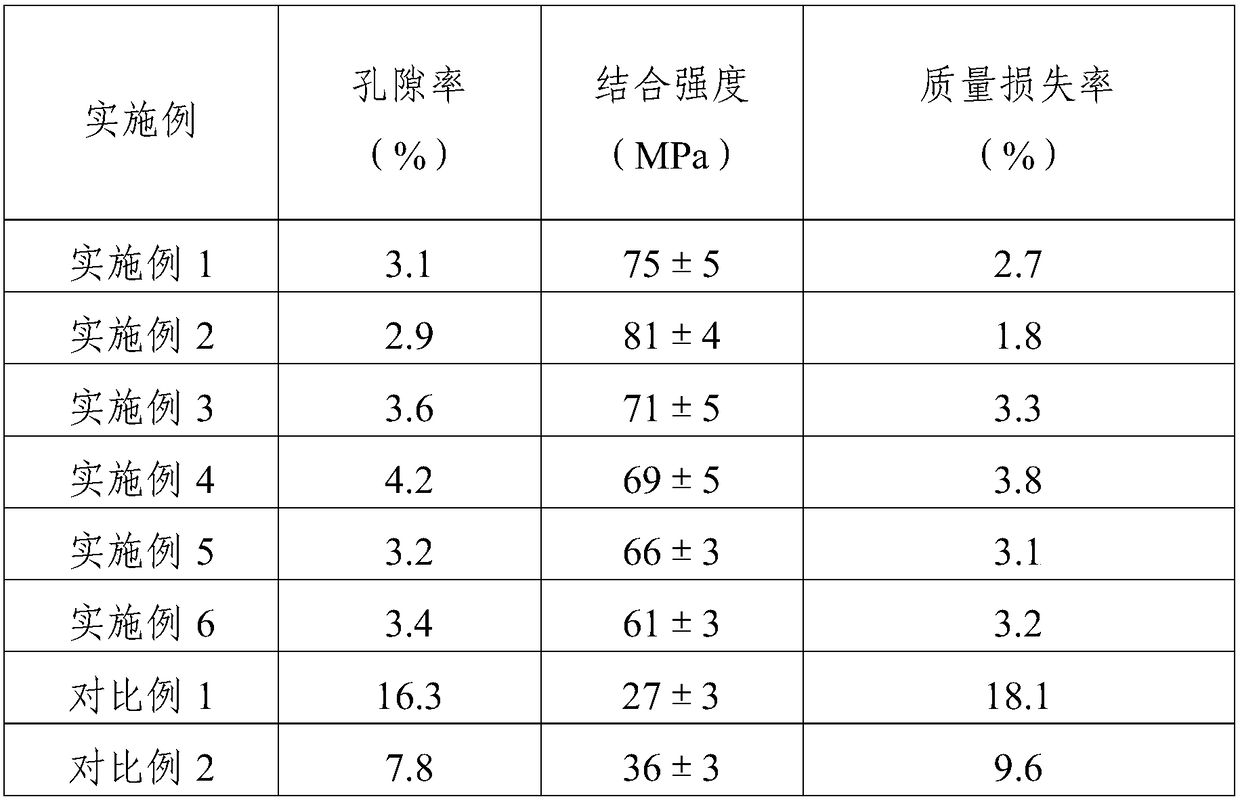

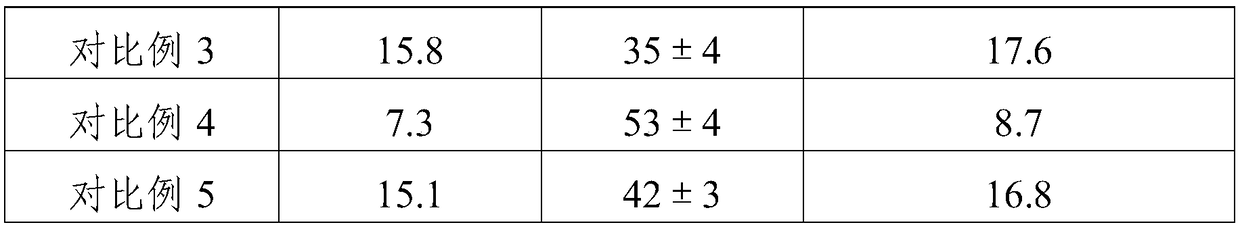

[0070] Adopt the test method identical with embodiment 1 to be coated with the C f / C-SiC ceramic matrix composite material matrix is carried out high-temperature oxidation test, to the Ta that this embodiment makes 4 HfC 5 - The porosity and bonding strength of the SiC gradient layer were tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com