A kind of preparation method of low thermal expansion coefficient, low moisture permeability uv-heat dual curing adhesive

A low thermal expansion coefficient, low moisture permeability technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of unclean removal of organic matter, gray-black appearance of spherical particles, etc., to achieve excellent waterproof Effects of vapor properties, low thermal expansion coefficient, and low moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

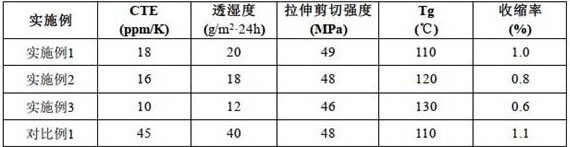

Examples

Embodiment 1

[0046] 12 parts of dicyclopentadiene phenol type epoxy resin, 12.4 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate, 3 parts of triaryl hexafluorosulfonium phosphate, Vicbase Add 0.55 parts of TC3632, 0.05 parts of 9,10-dibutoxyanthracene and 5 parts of 1,2,8,9-diepoxy-4-vinylcyclohexene into the stirring tank, under the condition of -0.1 MPa Stir for 0.5h, add 40 parts of spherical β-eucryptite particles, 25 parts of spherical silica and 1 part of additives, control the temperature not higher than 35°C, revolution 20 r / min, and autorotation 1000 r / min , disperse for 1 hour, add 1 part of fumed silica, stir evenly, control the temperature not higher than 35°C, under the conditions of revolution 20 r / min, rotation 1000 r / min, stir for 1 hour and then discharge, that is, low thermal expansion coefficient, Low moisture permeability UV-heat dual cure adhesive.

[0047] The spherical β-eucryptite particles are prepared according to the following method:

[0048]...

Embodiment 2

[0061] 7 parts of o-cresol novolac epoxy resin, 10.3 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate, 2.4 parts of triaryl hexafluorosulfonium phosphate, Vicbase TC3630 Add 0.6 parts, 0.04 parts of isopropylthioxanthone and 8 parts of 3-ethyl-3-oxetanemethanol into the stirring tank, stir for 0.5h under the pressure of -0.1 MPa, add spherical β- 30 parts of eucryptite particles, 40 parts of spherical silica and 1.2 parts of additives, controlled temperature not higher than 35°C, revolution 20 r / min, rotation 1000 r / min, disperse for 0.5-1h, add gas phase dioxide 0.46 parts of silicon, stir evenly, control the temperature not higher than 35°C, under the conditions of revolution 20 r / min, rotation 1000 r / min, stir for 1 hour and then discharge the material, that is, low thermal expansion coefficient and low moisture permeability UV-thermal dual curing adhesive.

[0062] The spherical β-eucryptite particles are prepared according to the following method:

[0...

Embodiment 3

[0076] 4 parts of anthracene-type epoxy resin, 6.25 parts of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester, 2.7 parts of diaryl hexafluoroantimonate iodonium salt, 0.3 parts of Vicbase TC3633, Add 0.05 parts of isopropylthioxanthone and 5 parts of 1,2,3,4-diepoxybutane into the stirred tank, stir for 0.5h under the pressure of -0.1 MPa, and add spherical β-euphane 40 parts of stone particles, 40 parts of spherical silica and 1.5 parts of additives, control the temperature not higher than 35 ° C, revolution 20 r / min, rotation 1000 r / min, disperse for 0.5-1h, add fumed silica 0.2 Stir evenly, control the temperature not higher than 35°C, under the conditions of revolution 20r / min, rotation 1000 r / min, stir for 1h and then discharge, then obtain low thermal expansion coefficient, low moisture permeability UV-heat dual-curing adhesive.

[0077] The spherical β-eucryptite particles are prepared according to the following method:

[0078] 1) Pre-synthesis of β-eucryptit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com