Ferrite material for motor and preparation method of ferrite material

A technology of ferrite materials and fine materials, which is applied in the field of ferrite materials for motors and its preparation, can solve the problems affecting the production efficiency of high-performance permanent magnet ferrite, the consistency of product performance cannot be guaranteed, and the preparation process is complicated. , to achieve the effect of improving magnetic properties, excellent magnetic properties, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

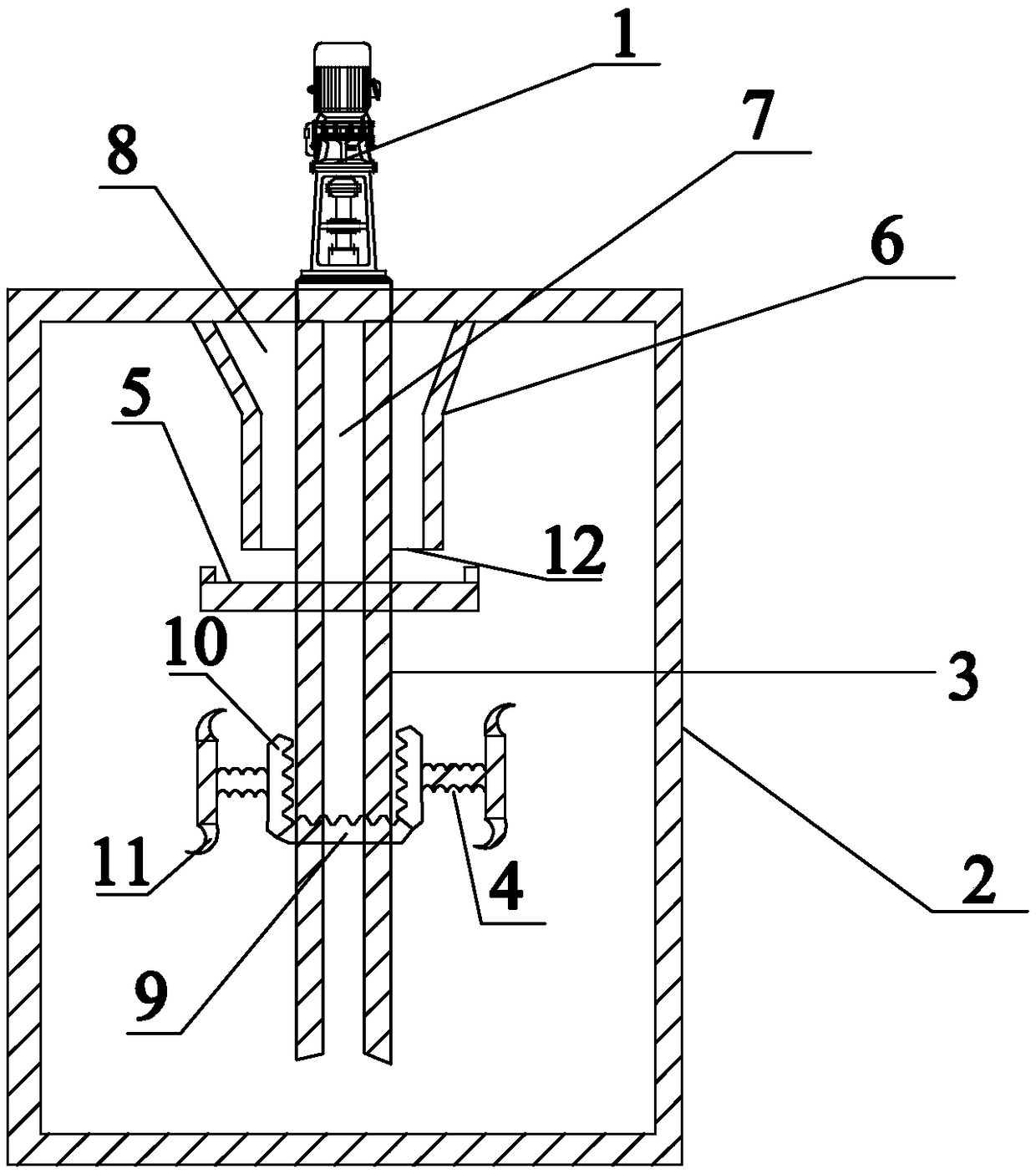

Image

Examples

Embodiment 1

[0035] (1) will pass through Sr 0.85 La 0.15 Fe 11.9 co 0.1 o 19 The calculated amounts of strontium carbonate, iron powder and additives are stored in the material barrel through automatic batching;

[0036] (2) Mix the powder obtained in (1) through a strong mixer for 8 minutes to ensure that it is evenly mixed;

[0037] (3) Pass the powder mixed in (2) through a two-stage compactor to ensure that the powder is mixed more evenly and the particle size is controlled to 2.5 μm;

[0038] (4) Use the powder obtained in (3) to make balls through a ball making machine. The ball diameter is controlled at 6-12mm. It is better to drop the balls at a height of 0.5 meters to the cement floor twice without breaking, so as to ensure the strength of the balls. ;

[0039] (5) Pass the ball obtained in (4) through a grate machine to remove fine balls and powder, and then enter the rotary kiln for sintering at 1300 ° C. The sintering time is controlled at 50 minutes, and solid reaction ...

Embodiment 2

[0043] (1) will pass through Sr 0.85 La 0.15 Fe 11.8 co 0.1 o 19 The calculated amounts of strontium carbonate, iron powder and additives are stored in the material barrel through automatic batching;

[0044] (2) Mix the powder obtained in (1) through a strong mixer for 13 minutes to ensure that it is evenly mixed;

[0045] (3) Pass the powder mixed in (2) through a two-stage compactor to ensure that the powder is mixed more evenly and the particle size is controlled to 2.0 μm;

[0046] (4) Use the powder obtained in (3) to make balls through a ball making machine. The ball diameter is controlled at 6-12mm. It is better to drop the balls at a height of 0.5 meters to the cement floor twice without breaking, so as to ensure the strength of the balls. ;

[0047] (5) Pass the ball obtained in (4) through a grate machine to remove the fine balls and powder, and then enter the rotary kiln for sintering at 1330 ° C. The sintering time is controlled at 40 minutes, and the solid ...

Embodiment 3

[0051] (1) will pass through Sr 0.85 La 0.15 Fe 11.8 co 0.1 o 19 The calculated amounts of strontium carbonate, iron powder and additives are stored in the material barrel through automatic batching;

[0052] (2) Mix the powder obtained in (1) through a strong mixer for 13 minutes to ensure that it is evenly mixed;

[0053] (3) Pass the powder mixed in (2) through a two-stage compactor to ensure that the powder is mixed more evenly and the particle size is controlled to 3.0 μm;

[0054] (4) Use the powder obtained in (3) to make balls through a ball making machine. The ball diameter is controlled at 6-12mm. It is better to drop the balls at a height of 0.5 meters to the cement floor twice without breaking, so as to ensure the strength of the balls. ;

[0055] (5) Pass the ball obtained in (4) through a grate machine to remove fine balls and powder, and then enter the rotary kiln for sintering at 1350 ° C. The sintering time is controlled at 30 minutes, and solid reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com