Amphiphilic platinum (II) complex and preparation thereof and application thereof to construction of white light-emitting system

A complex and amphiphilic technology, applied in platinum group organic compounds, platinum organic compounds, luminescent materials, etc., can solve the problem of low quantum yield, achieve excellent luminescence performance, simple preparation method, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Synthesis of compounds of formula Ⅰ-1

[0035] Under nitrogen protection, 369mg (4mmol) propargylamine hydrochloride, 1.3mL triethylamine and 40mL methylene chloride were successively added into a 250mL three-necked flask; 897mg (2mmol)) cholesterol chloroformate was added successively in a constant pressure funnel and 100 mL of dichloromethane were added dropwise into a three-necked flask under ice-bath conditions and stirred, and stirred at room temperature for 12 hours after the dropwise addition was completed. After the reaction was finished, the reaction solution was washed three times with distilled water, the organic phases were combined, and after drying over anhydrous sodium sulfate, the solvent was evaporated under reduced pressure to obtain a crude product. The volume ratio of the gained crude product to dichloromethane and sherwood oil was 5: The mixed solution of 1 was used as the mobile phase, and silica gel was used as the stationary phase to carry out...

Embodiment 2

[0043] Application of the Amphiphilic Platinum(II) Complex Prepared in Example 1 in the Construction of a White Light Emitting System

[0044] Using the mixture of dimethyl sulfoxide and water with different water contents as solvent, prepare a solution of amphiphilic platinum(II) complex with a concentration of 50 μmol / L, heat at 50-60°C for 1 hour, and cool naturally to room temperature Let stand for 24 hours.

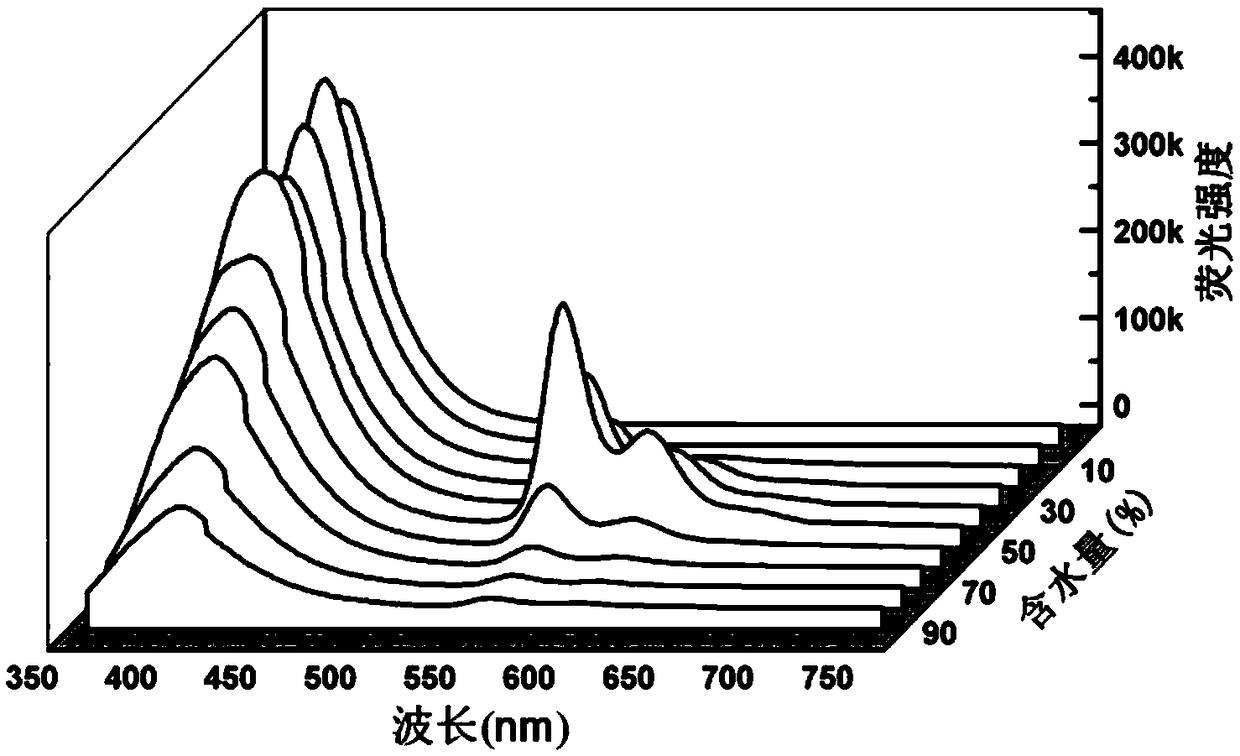

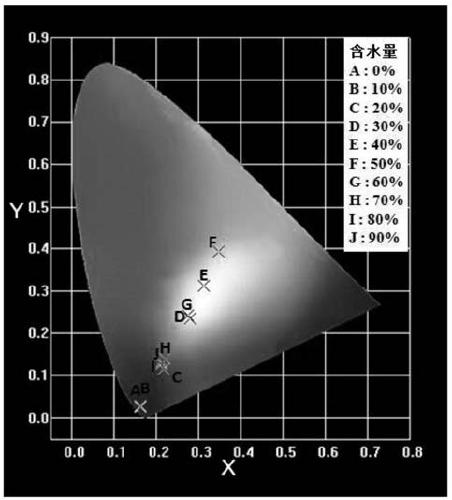

[0045] When the volume concentration of water in the solvent is 30%, 40%, 50% and 60%, the amphiphilic platinum (II) complex solution is excited with a light source with a wavelength of 340 nm at room temperature, and the system can emit white light (fluorescence emission) Spectrum see figure 1 , see the chromaticity coordinate diagram figure 2 ), where the volume concentration of water is 50%, the quantum yield is the highest, which is 5.8%.

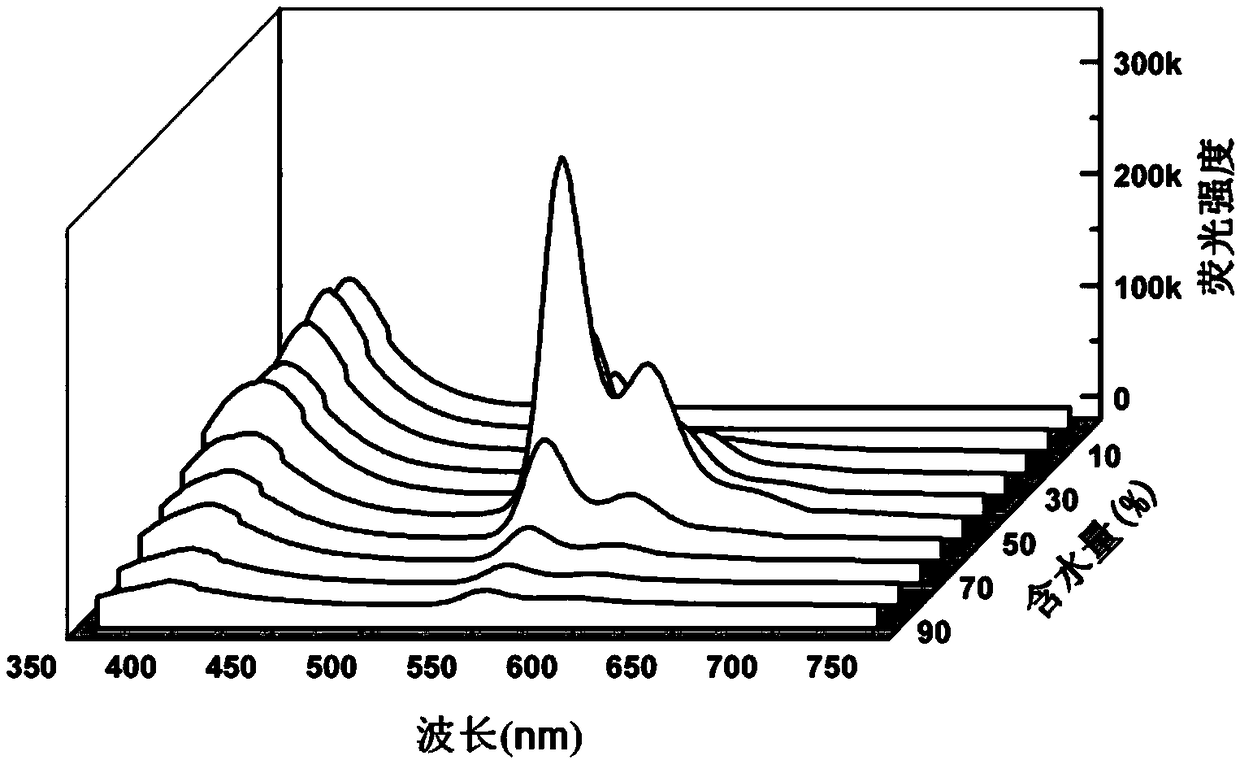

[0046] When the volume concentration of water in the solvent is 20%, 70%, 80% and 90% respectively, the amphiphilic plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com