A general purpose cutting fluid

A cutting fluid, general-purpose technology, applied in the field of metal cutting, can solve problems such as precipitation, unstable working fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

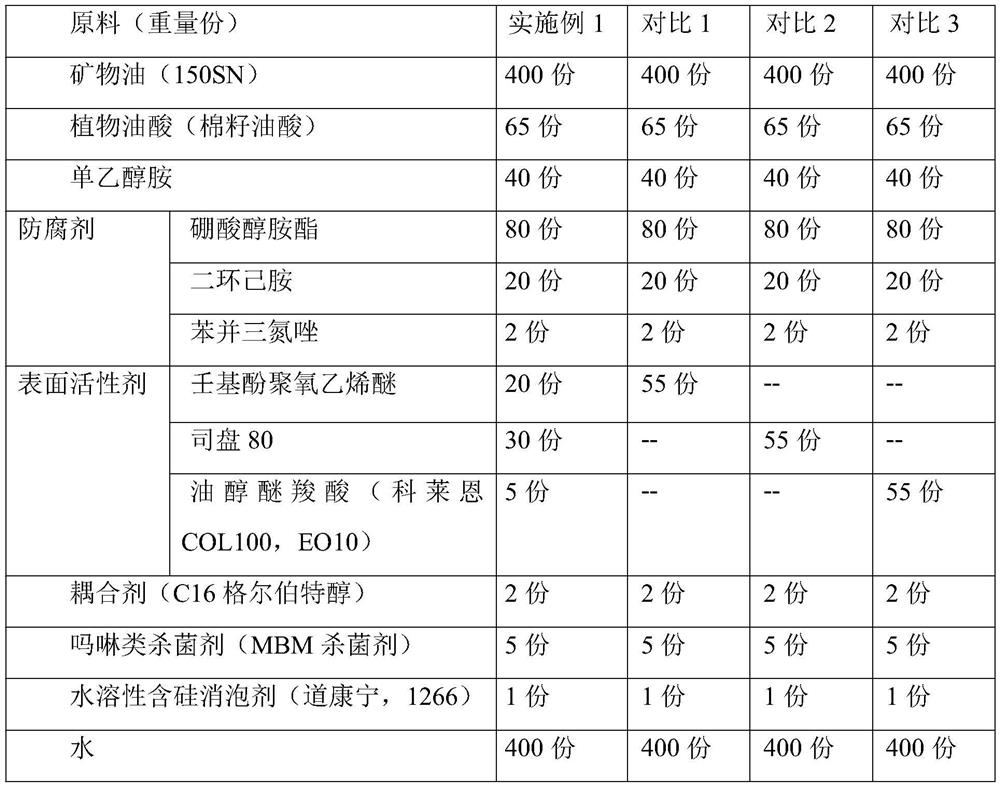

Embodiment 1

[0027]

[0028] Preparation process of cutting fluid: heat mineral oil to 60°C, add vegetable oleic acid, couplant, monoethanolamine, preservative, and surfactant in turn, stir for 0.5h, add water, stir for 0.5h, cool down to 30°C, add sterilizing agent, antifoaming agent, stir for 1h, let stand for 1-2h, filter and fill.

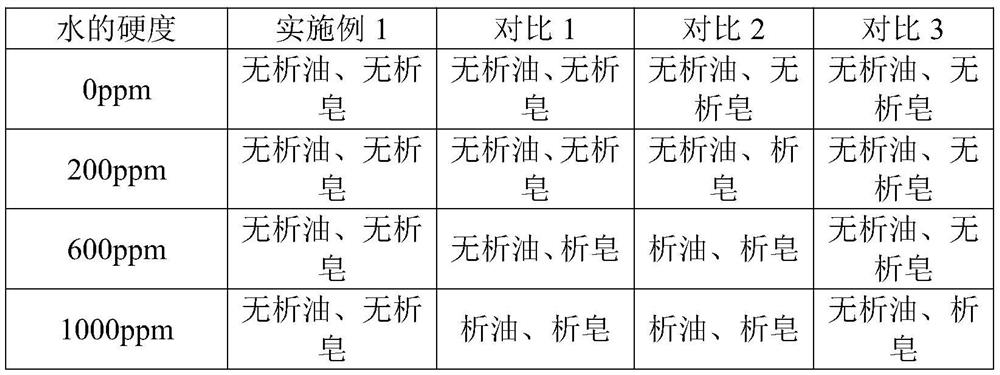

[0029] Stability test of cutting fluid to hard water:

[0030] Experimental process: Put 100ml of 5% cutting fluid diluted with hard water into a stoppered measuring cylinder, and let it stand at room temperature for 24 hours.

[0031]

[0032] Note: The oil separation is a transparent liquid layer, and the soap separation is a white to yellow flocculent suspension.

[0033] The results of the stability test show that nonylphenol polyoxyethylene ether, Span 80 and oleyl ether carboxylic acid have a synergistic effect, which can significantly improve the hard water resistance of the cutting fluid.

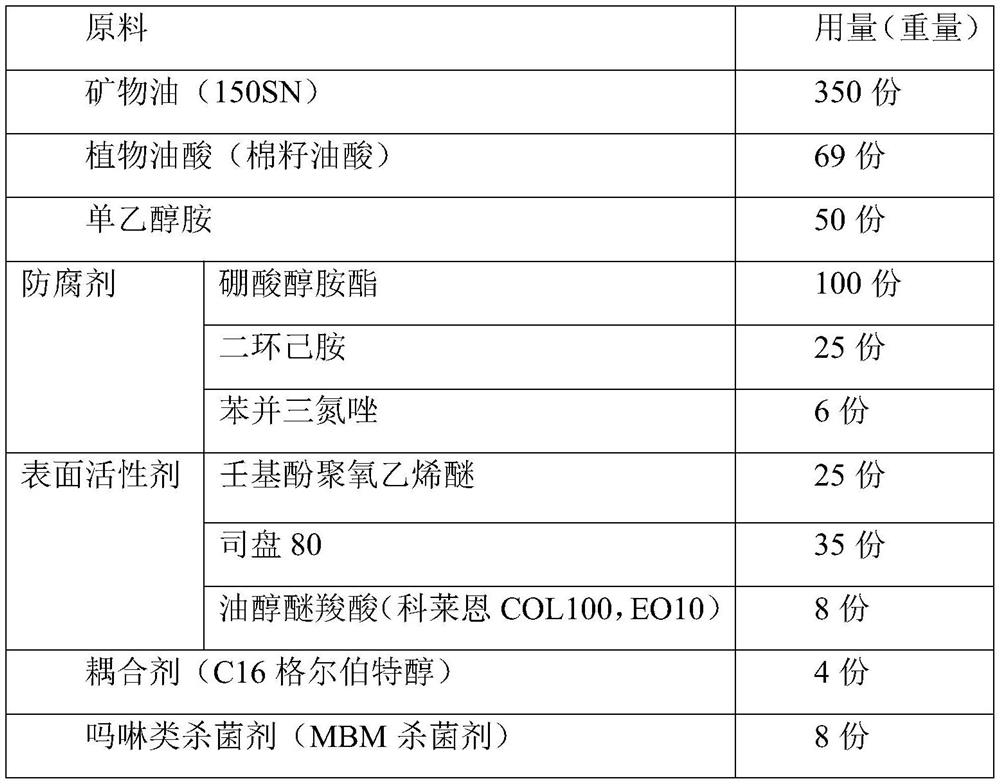

Embodiment 2

[0035]

[0036]

[0037] Preparation process of cutting fluid: heat mineral oil to 60°C, add vegetable oleic acid, couplant, monoethanolamine, preservative, and surfactant in turn, stir for 0.5h, add water, stir for 0.5h, cool down to 30°C, add sterilizing agent, antifoaming agent, stir for 1h, let stand for 1-2h, filter and fill.

Embodiment 3

[0039]

[0040] Preparation process of cutting fluid: heat mineral oil to 60°C, add vegetable oleic acid, couplant, monoethanolamine, preservative, and surfactant in turn, stir for 0.5h, add water, stir for 0.5h, cool down to 30°C, add sterilizing agent, antifoaming agent, stir for 1h, let stand for 1-2h, filter and fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com