Porphyrin memristor with biological synapse analogue function, preparation method and application thereof

A technology for simulating function and memristor, which is applied in the field of memristor with biological synapse simulation function and its preparation, which can solve the bottleneck of tolerance, reliability, batch repeatability, and is not suitable for flexible and high-energy-consuming manufacturing processes. , the slow progress of materials and devices, etc., to achieve the effect of high output repeatability, easy structure, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

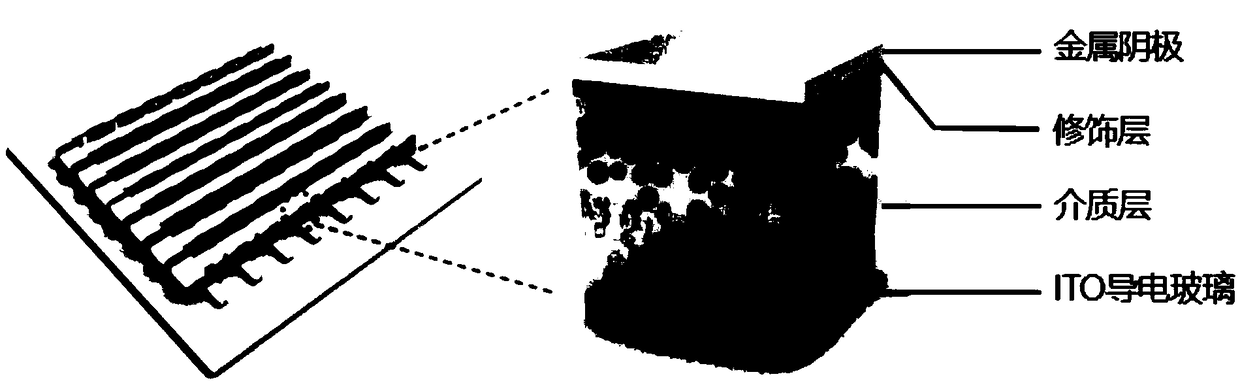

[0039] (1) Carry out standard substrate cleaning on ITO conductive glass, firstly through acetone, ethanol, ultra-clean water cleaning, then through acetone, ethanol, ultra-clean water three-step ultrasonic cleaning, then dry the substrate, and place Dry in an oven at 120°C for 20 minutes;

[0040] (2) Treat the dried ITO conductive glass with ultraviolet and ozone for 5 minutes;

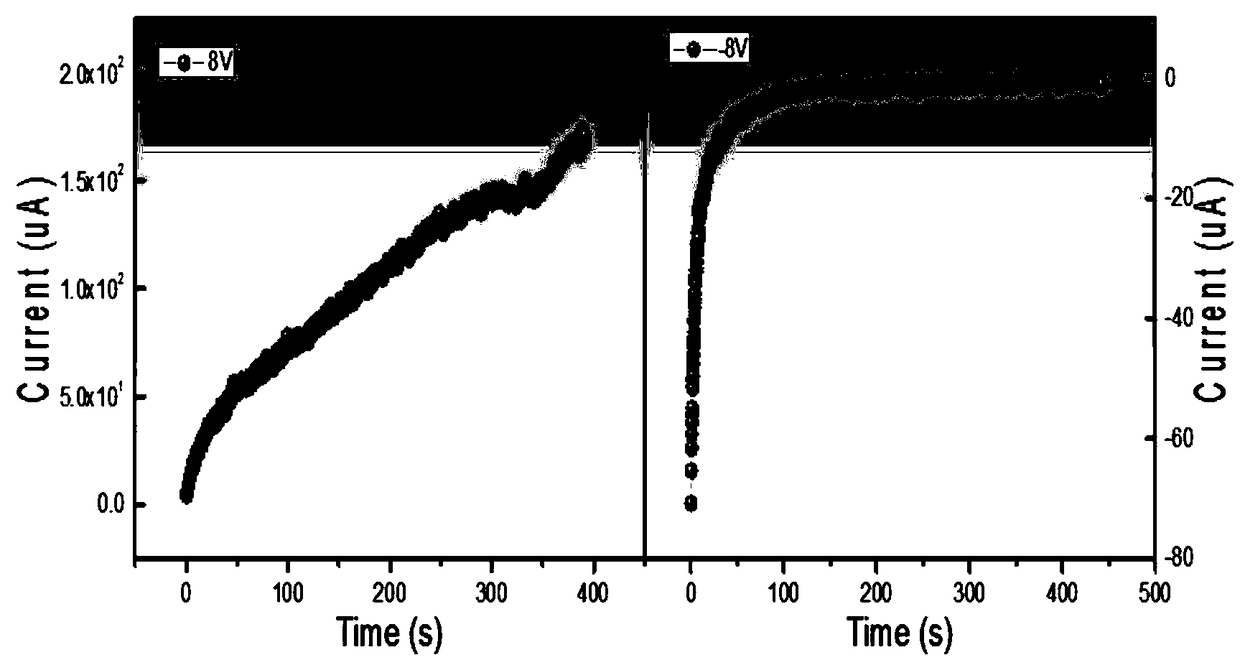

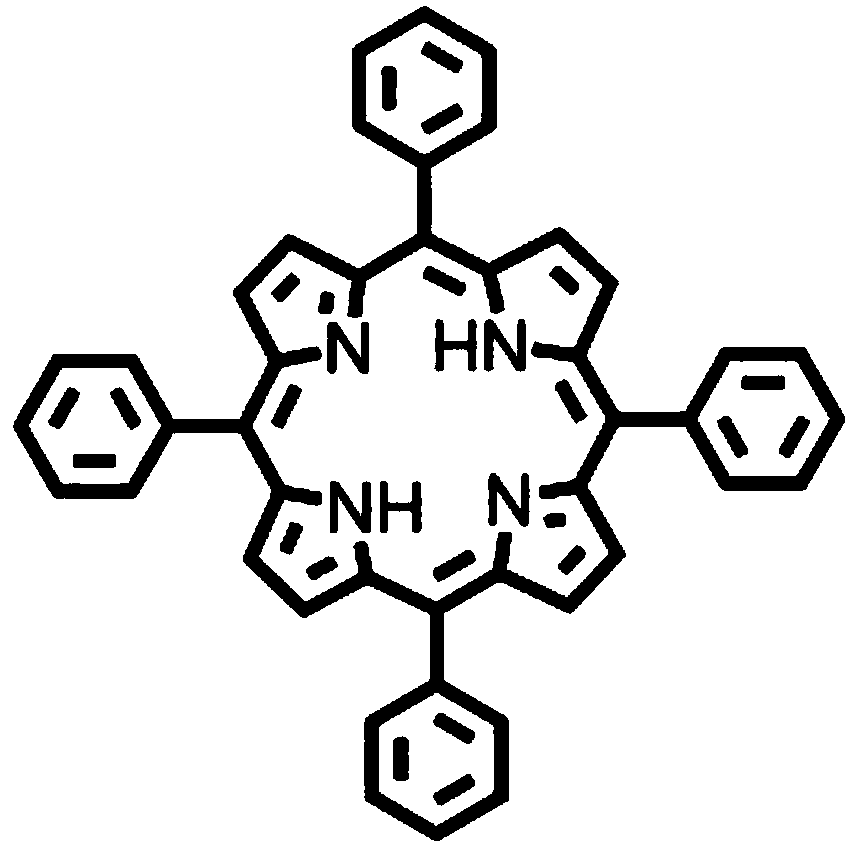

[0041] (3) Put the treated ITO conductive glass into the vacuum evaporation equipment, and the pressure in the vacuum chamber is lower than 5×10 - 5 After Pa, begin to vapor-deposit the dielectric layer, the modification layer and the metal cathode in sequence. The material of the dielectric layer is porphyrin small molecule TPP, and the evaporation rate is about The thickness of the porphyrin layer is about 60nm; the vacuum evaporation material of the modification layer is aluminum, and the aluminum oxide Al is formed through the autoxidation reaction. 2o 3-x , the evaporation rate is controll...

Embodiment 2

[0045] (1) Carry out standard substrate cleaning on ITO conductive glass, firstly through acetone, ethanol, ultra-clean water cleaning, then through acetone, ethanol, ultra-clean water three-step ultrasonic cleaning, then dry the substrate, and place Dry in an oven at 120°C for 20 minutes;

[0046] (2) Treat the dried ITO conductive glass with ultraviolet and ozone for 5 minutes;

[0047] (3) Put the treated ITO conductive glass into the vacuum evaporation equipment, and the pressure in the vacuum chamber is lower than 5×10 - 5 After Pa, start to vapor-deposit the dielectric layer, the modification layer and the metal cathode in sequence. The material of the dielectric layer is porphyrin polymer, and the evaporation rate is about The thickness of the porphyrin layer is about 60nm; the vacuum evaporation material of the modification layer is titanium, which generates titanium oxide through autoxidation reaction, and the evaporation rate is controlled at The thickness is ab...

Embodiment 3

[0050] (1) Carry out standard substrate cleaning on ITO conductive glass, firstly through acetone, ethanol, ultra-clean water cleaning, then through acetone, ethanol, ultra-clean water three-step ultrasonic cleaning, then dry the substrate, and place Dry in an oven at 120°C for 20 minutes;

[0051] (2) Treat the dried ITO conductive glass with ultraviolet and ozone for 5 minutes;

[0052] (3) Put the treated ITO conductive glass into the vacuum evaporation equipment, and the pressure in the vacuum chamber is lower than 5×10 - 5 After Pa, begin to vapor-deposit the dielectric layer, the modification layer and the metal cathode in sequence, the material of the dielectric layer is , and the evaporation rate is about The thickness of the porphyrin layer is about 60nm; the vacuum evaporation material of the modification layer is indium gallium zinc, which generates indium gallium zinc oxide through self-oxidation reaction, and the evaporation rate is controlled at The thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com