Method for improving functional characteristics of rice glutenin through phosphorylation treatment

A glutenin and phosphorylation technology, which is applied in the field of plant protein modification, can solve the problems of difficult control of enzymatic hydrolysis, difficult continuous production, expensive equipment, etc., to achieve improved functional properties, low manufacturing cost, and high solubility. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

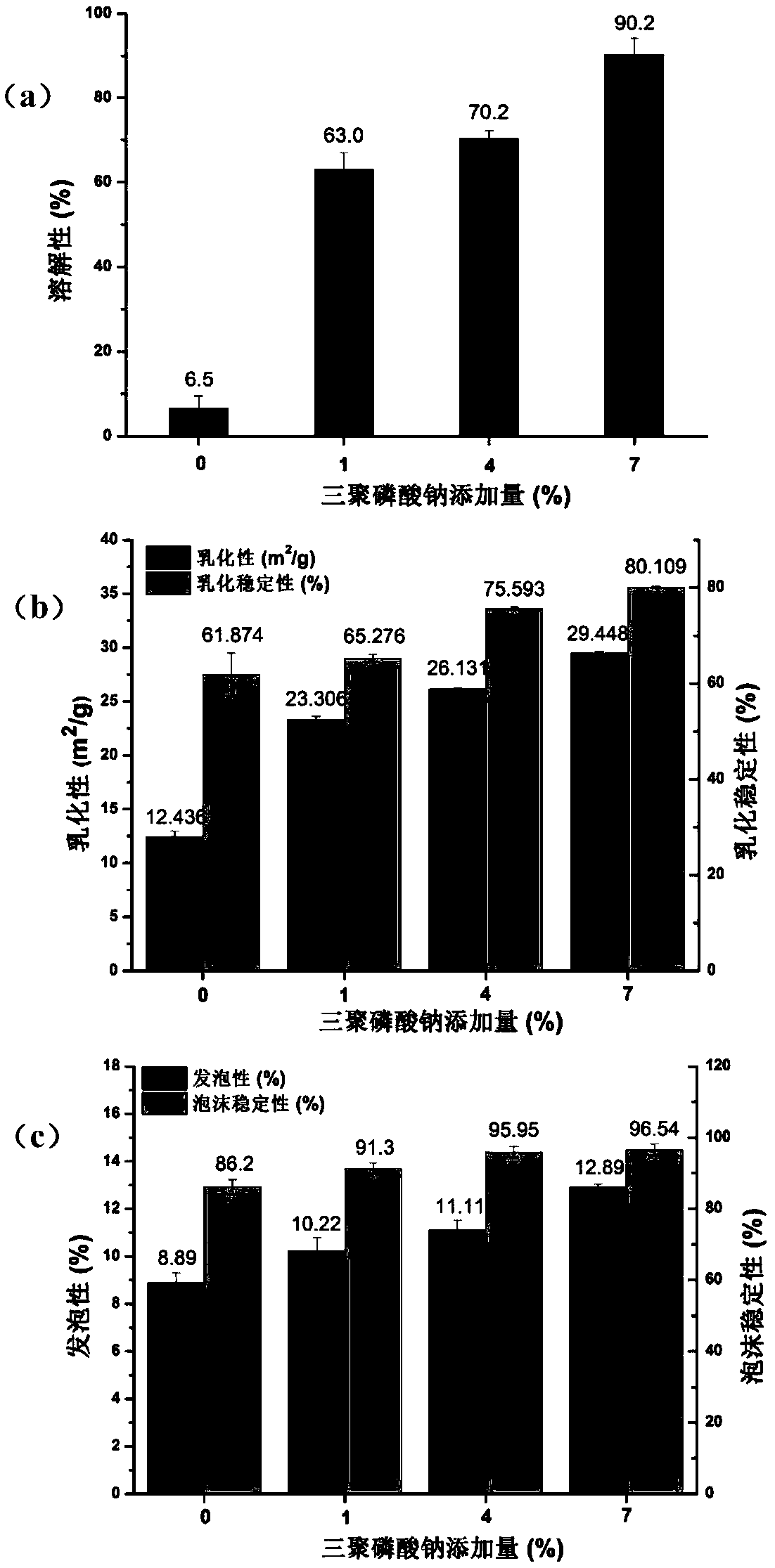

Embodiment 1

[0026] 1. Use broken rice as raw material, after grinding through a 100-mesh sieve, mix the broken rice flour and distilled water at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, and mix the obtained precipitate with 5wt% NaCl solution at a concentration of 1g : Mix at a ratio of 10mL, stir at room temperature for 2 hours and then centrifuge, mix the obtained precipitate with NaOH solution with a concentration of 0.05M at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, take the supernatant, use 1M NaOH solution HCl solution adjusts the pH value of the supernatant to 5.4, centrifuges to get the precipitate, freezes and dries after washing with water, and obtains rice gluten; rice gluten is added in the phosphate buffered saline solution with a pH value of 7.0, and mixed evenly to form 1% (w / v) concentration of protein dispersion;

[0027] 2. Add phosphorylation reagent (the ratio of phosphorylation reagent to rice...

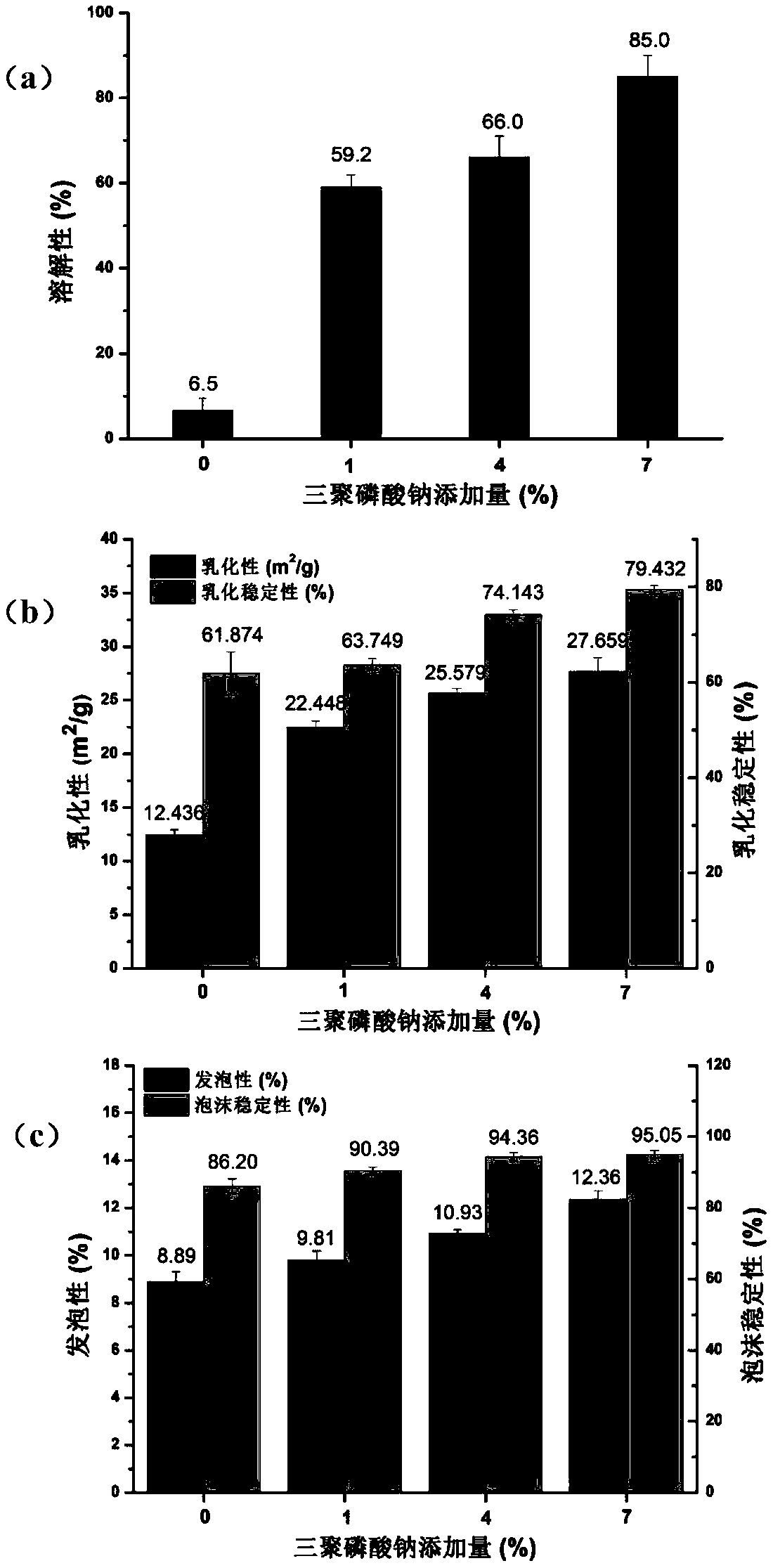

Embodiment 2

[0032] 1. Use broken rice as raw material, after grinding through a 100-mesh sieve, mix the broken rice flour and distilled water at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, and mix the obtained precipitate with 5wt% NaCl solution at a concentration of 1g : Mix at a ratio of 10mL, stir at room temperature for 2 hours and then centrifuge, mix the obtained precipitate with NaOH solution with a concentration of 0.05M at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, take the supernatant, use 1M NaOH solution HCl solution adjusts the pH value of the supernatant to 5.4, centrifuges to get the precipitate, freezes and dries after washing with water, and obtains rice gluten; adds rice gluten in the phosphate buffered saline solution with a pH value of 7.0, mixes uniformly, and forms a 5% (w / v) concentration of protein dispersion;

[0033]2. Add phosphorylation reagent (the ratio of phosphorylation reagent to rice ...

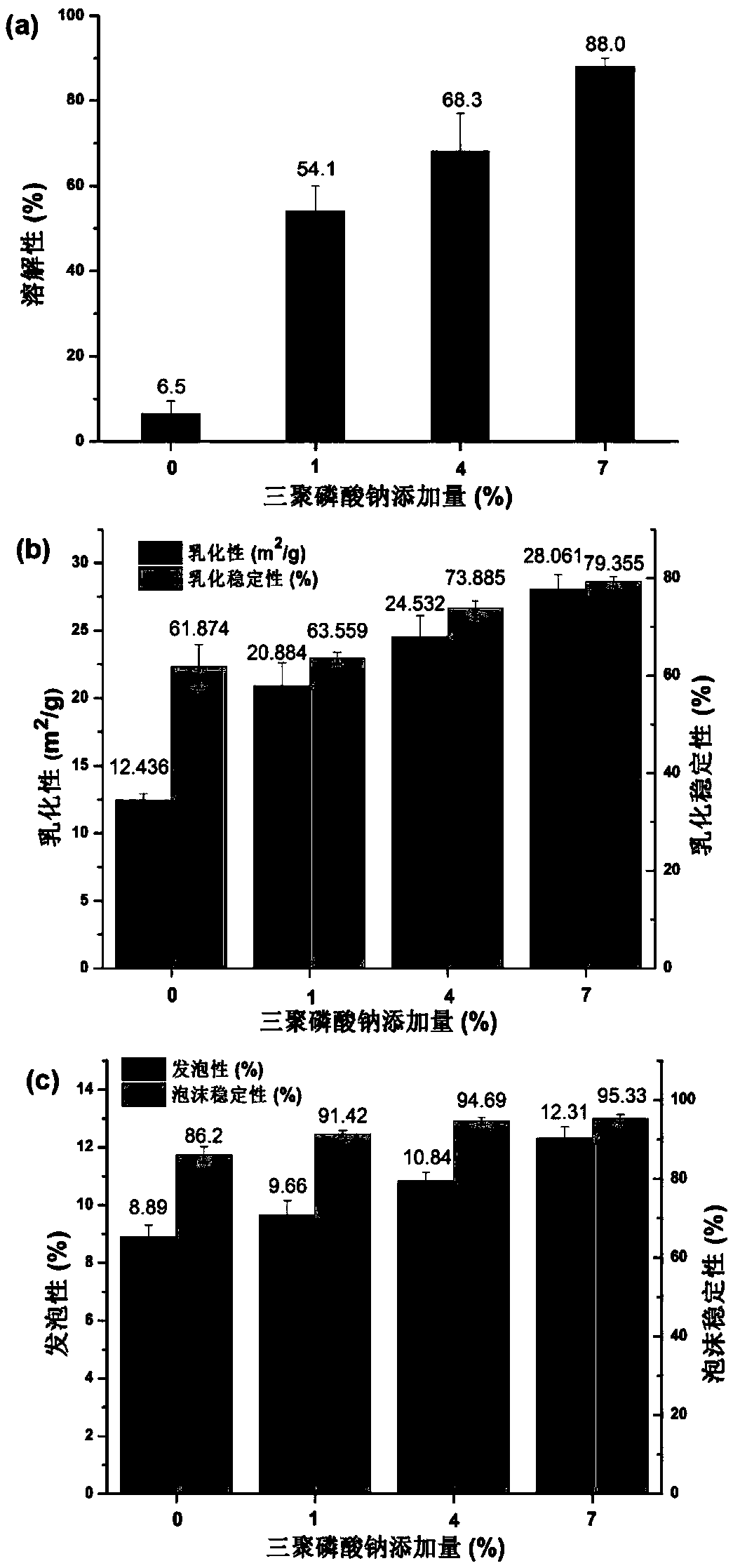

Embodiment 3

[0038] 1. Use broken rice as raw material, after grinding through a 100-mesh sieve, mix the broken rice flour and distilled water at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, and mix the obtained precipitate with 5wt% NaCl solution at a concentration of 1g : Mix at a ratio of 10mL, stir at room temperature for 2 hours and then centrifuge, mix the obtained precipitate with NaOH solution with a concentration of 0.05M at a ratio of 1g: 10mL, stir at room temperature for 2 hours and then centrifuge, take the supernatant, use 1M NaOH solution HCl solution adjusts the pH value of the supernatant to 5.4, centrifuges to get the precipitate, freezes and dries after washing with water, and obtains rice gluten; rice gluten is added in the phosphate buffered saline solution with a pH value of 7.0, and mixed uniformly to form a 10% (w / v) concentration of protein dispersion;

[0039] 2. Add phosphorylation reagent (the ratio of phosphorylation reagent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emulsifying | aaaaa | aaaaa |

| Emulsifying | aaaaa | aaaaa |

| Emulsifying | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com