Process for harmlessly producing iron oxide red pigments by alkaline circulation method

A red iron oxide, alkali recycling technology, applied in the direction of iron oxide, iron oxide/hydroxide, fibrous filler, etc., can solve the problem of affecting economic benefits, increasing the viscosity of the slurry system, and not conforming to the ammonia neutralization process. features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

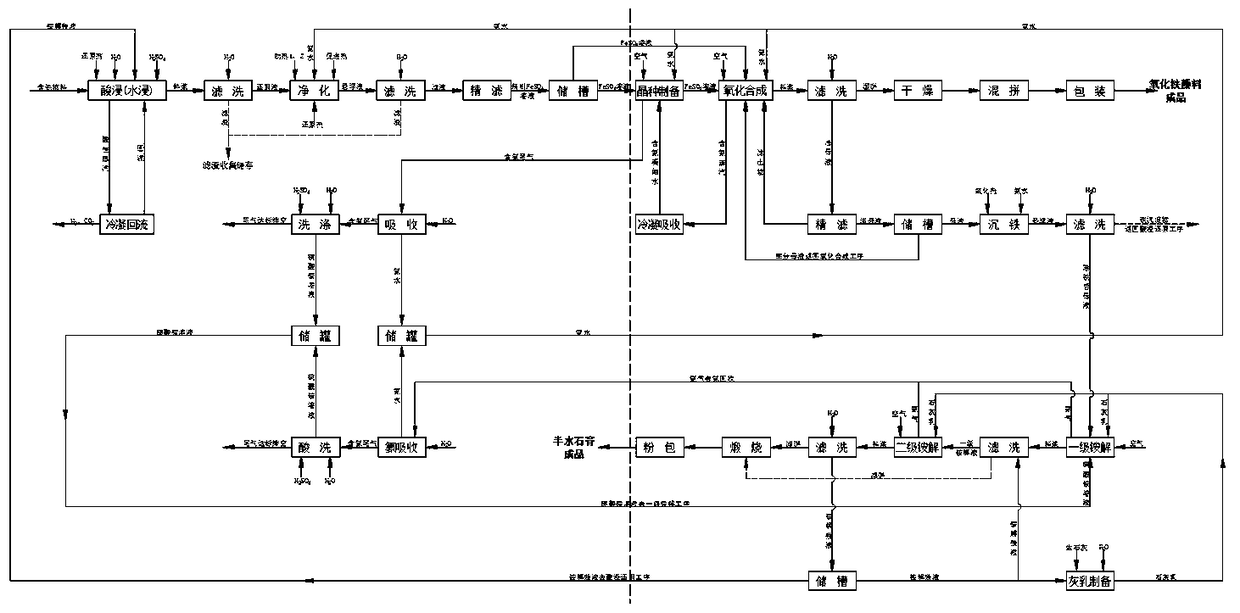

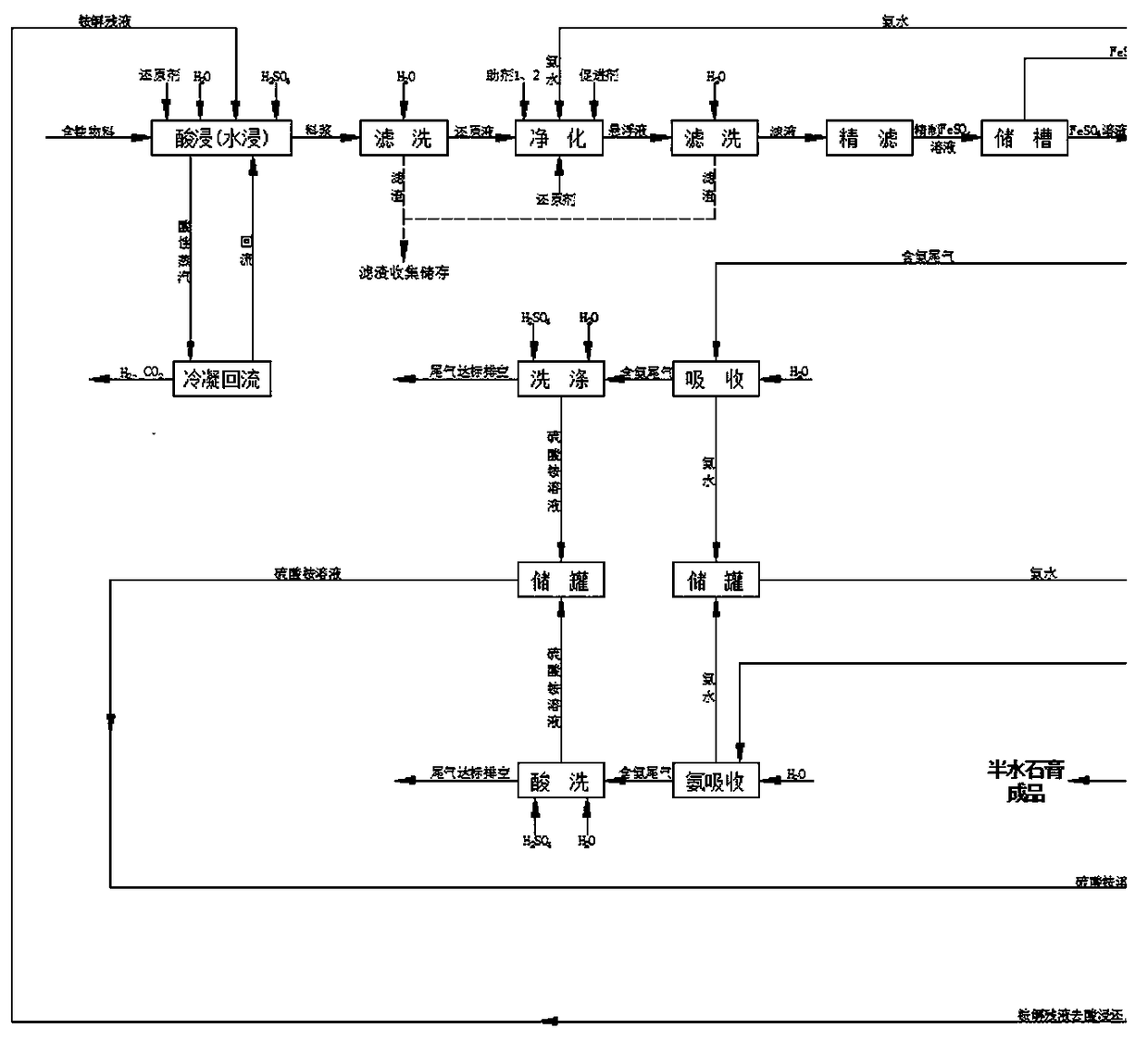

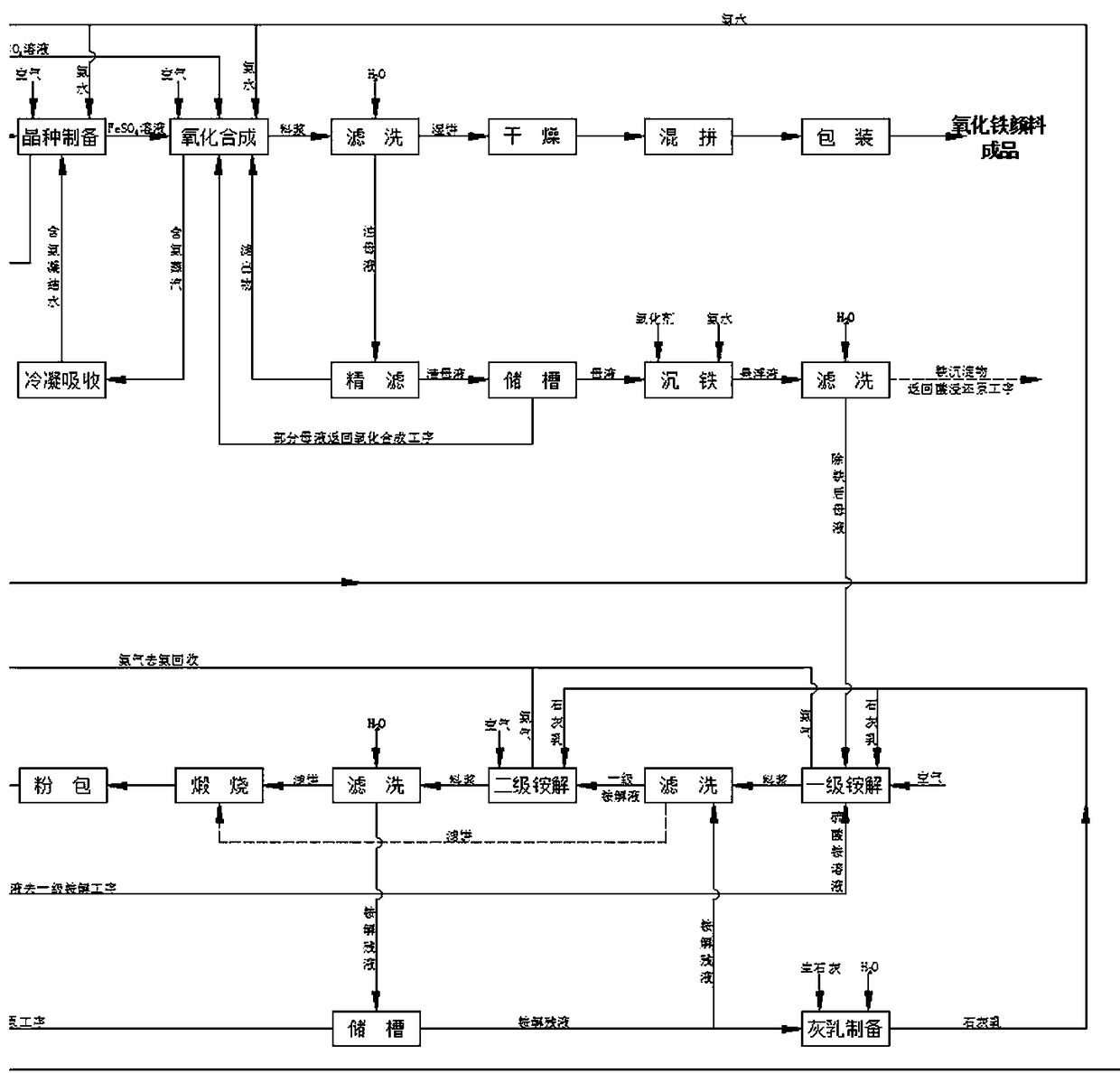

[0048] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-3 Shown: a process for the harmless production of iron oxide red pigment by an alkali cycle method, comprising the following steps:

[0049] Step 1: the preparation of ferrous sulfate solution:

[0050] (1) Using iron-containing minerals or iron-containing solid waste as raw materials;

[0051] ① Pulverize iron-containing minerals or iron-containing solid waste to obtain iron-containing material powder, and then put the obtained powder in the acid leaching process, and in the acid leaching reactor with the ammonium solution residue from the iron oxide red mother liquor recovery ammonia water process Mix according to the solid-liquid ratio of 1:1~5, and add appropriate amount of sulfuric acid for leaching, so that the iron in iron-containing minerals or iron-containing solid waste is converted into ferric sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com