A method for reducing sulfur trioxide in nonferrous smelting flue gas by using metal sulfide reduction

A metal sulfide and smelting flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large consumption of reducing agent, poor reduction selectivity, high cost, etc., and achieve easy industrial application and high reduction rate High, easily accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

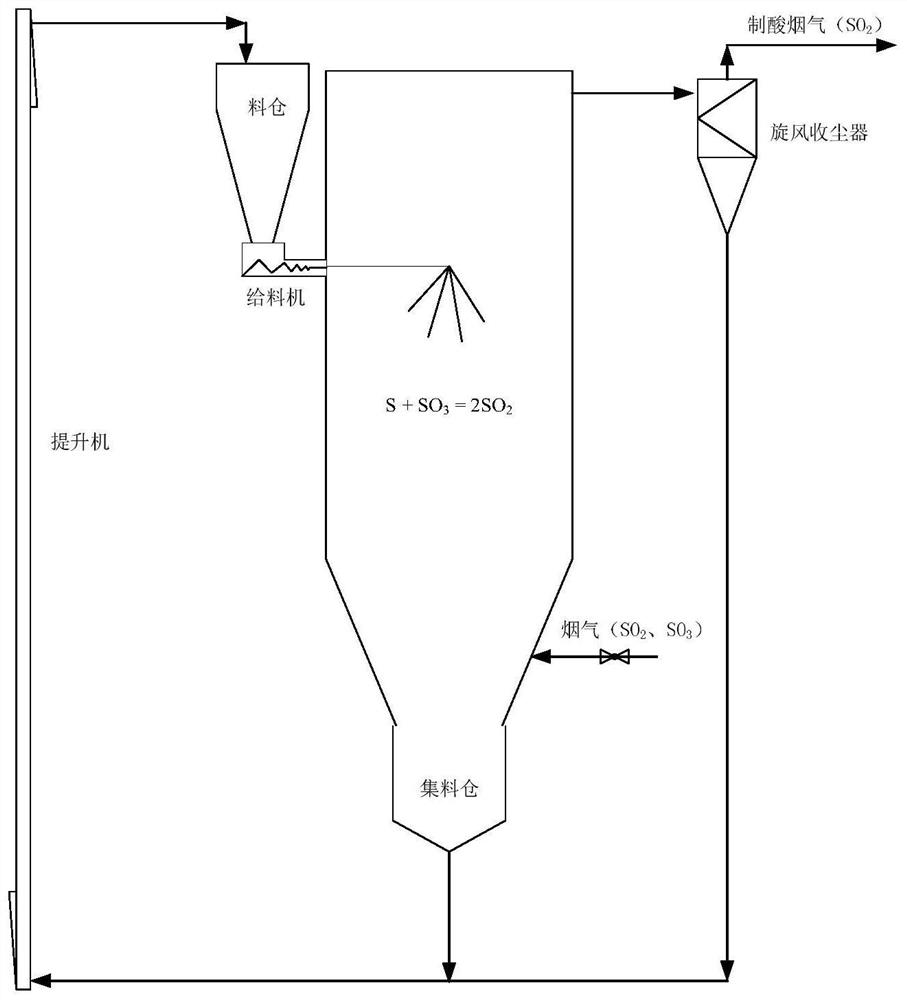

Embodiment 1

[0030] Use zinc sulfide concentrate powder as a reducing agent (total sulfur is 29.88%, zinc content is 54.87%, particle size is -200 mesh), it is added into the silo, and is transported to the top of the reduction reaction tower by a feeder to feed The feed nozzle is used to disperse it into the reduction tower under the action of the nozzle, and the feeding speed is 8.09t / h (35 times). Then, the flue gas (SO 2 12.47-14.52%, SO 3 0.64-0.71%, the temperature is 182-196 ℃), the control flue gas flow is 3.2-3.6 million m 3, so that its residence time in the tower is 45s. The flue gas after the reaction is led out from the top of the tower, and after dust collection by the cyclone, the flue gas of acid making is obtained. During operation, in addition to detecting the flue gas flow and temperature, it is also necessary to regularly discharge slag and replenish new zinc sulfide concentrate powder. The obtained slag can be used in boiling roasting process or wet leaching proces...

Embodiment 2

[0035] Use zinc sulfide concentrate powder as the reducing agent (total sulfur is 31.45%, zinc content is 57.28%, particle size is -180 mesh), it is added into the silo, and is transported to the top of the reduction reaction tower by the feeder. The feed nozzle is used to disperse it into the reduction tower under the action of the nozzle, and the feeding speed is 11.87t / h (40 times). Then, the flue gas (SO 2 18.56-19.51%, SO 3 0.82-0.91%, the temperature is 292-318 ℃), the control flue gas flow rate is 34,000-35,000 m 3 , so that its residence time in the tower is 36s. The flue gas after the reaction is led out from the top of the tower, and after dust collection by the cyclone, the flue gas of acid making is obtained. During operation, in addition to detecting the flue gas flow and temperature, it is also necessary to regularly discharge slag and replenish new zinc sulfide concentrate powder. The obtained slag can be used in boiling roasting process or wet leaching proc...

Embodiment 3

[0040] Use copper sulfide concentrate powder as the reducing agent (total sulfur is 32.31%, copper content is 22.52%, particle size is -325 mesh), it is added into the silo, and is transported to the top of the reduction reaction tower through the feeder. The feed nozzle is used to disperse it into the reduction tower under the action of the nozzle, and the feeding speed is 6.24t / h (24 times). Then, the flue gas (SO 2 27.89-29.33%, SO 3 1.23-1.41%, the temperature is 92-127 ℃), the control flue gas flow rate is 18,000-22,000 m 3 , so that the residence time in the tower is 80s. The flue gas after the reaction is led out from the top of the tower, and after dust collection by the cyclone, the flue gas of acid making is obtained. During operation, in addition to detecting the flue gas flow and temperature, it is also necessary to regularly discharge slag and replenish new zinc sulfide concentrate powder. The obtained slag can be used in boiling roasting process or wet leachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com