Preparation method of highly dispersed hierarchical pore H-ZSM-5 molecular sieve of framework metal

A framework metal, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of poor thermal stability, weak interaction ability, etc., and achieve low cost and orderly. The effect of uniform pore structure and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

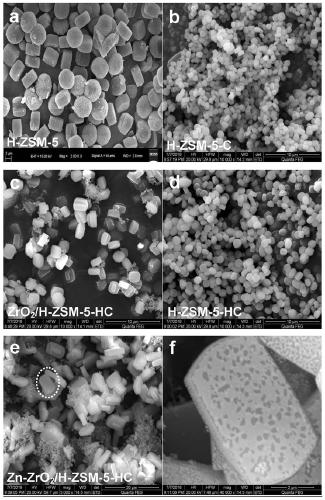

[0028] 1. Oxidative modification of commercial carbon black

[0029] Sodium hypochlorite, hydrogen peroxide and nitric acid were selected as oxidants respectively, and 25wt% oxidant-modified commercial carbon black (Carbot BP2000, particle size = 12 nm) was configured, 100 mL of oxidant was put into a polytetrafluoroethylene cup, and 2 g of Carbon black, mechanically stirred for 24 h. Take out the mixed solution, wash it, filter it with suction, place it in a blast drying oven at 60 o After drying at C for 4 h, at 100 o C dried overnight. Collect samples, name NaClO 2 -C, H 2 o 2 -C and HNO 3 -C.

[0030] In the present invention, when sodium hypochlorite is used, light-shielding treatment is required to avoid photodecomposition.

[0031] 2. Preparation of Nanoscale Bimetallic (Zn-Zr) Species

[0032] According to the molar ratio Zn:Zr=1:X (X=100~250), zirconium nitrate pentahydrate and zinc chloride aqueous solution were mixed, ultrasonically dispersed for 30 min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com