Preparation process of high-purity alpha-ethyl linolenate

A preparation technology of ethyl linolenate, which is applied in the field of preparation of unsaturated fatty acids and α-ethyl linolenate, can solve the problems of high energy consumption, difficulty in industrialization, and large pollution, and achieve long storage time, Effects of process simplification, energy consumption and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

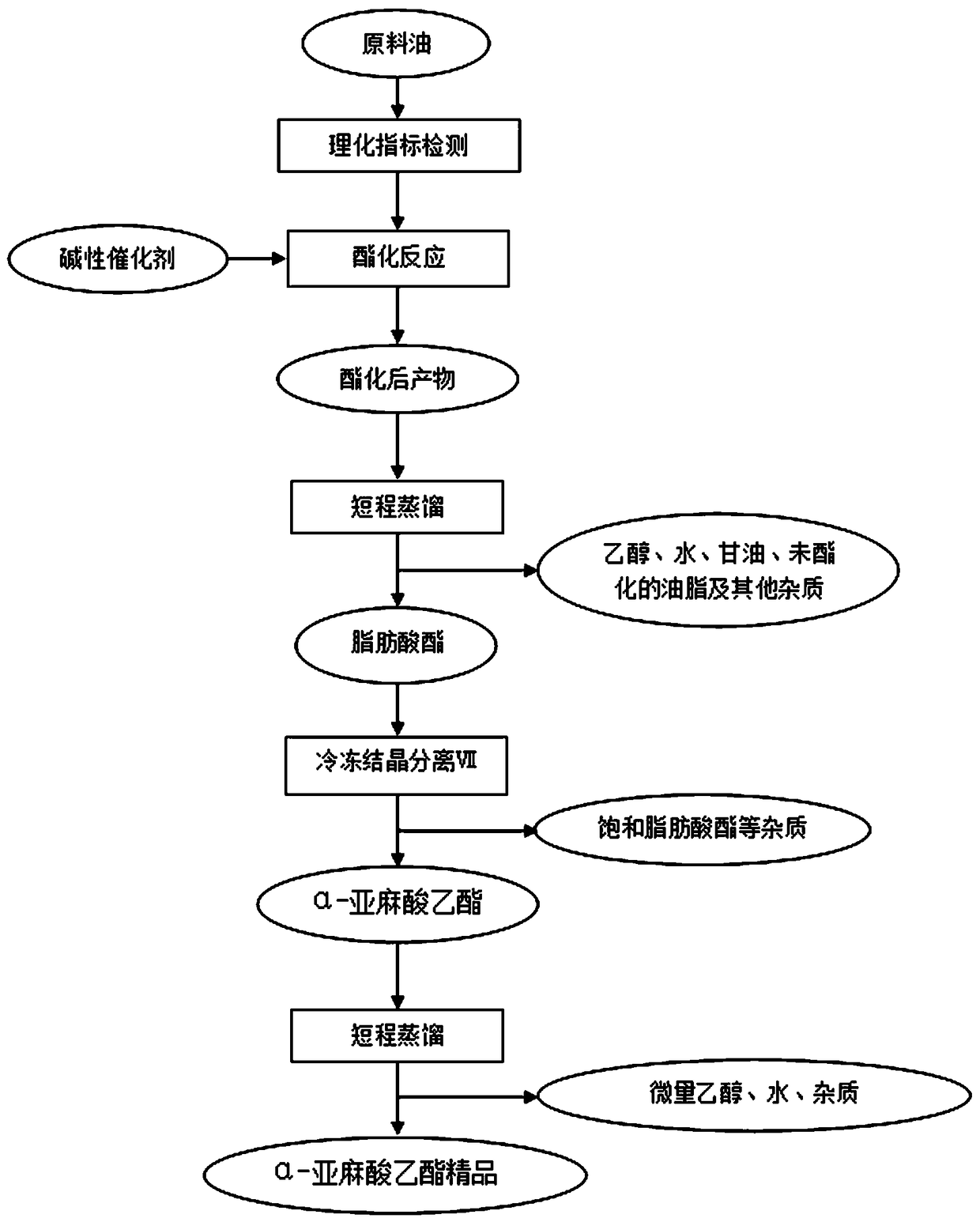

Method used

Image

Examples

Embodiment 1

[0024] 1. Detection and pretreatment: The purchased perilla oil (α-linolenic acid content ≥ 62%) is tested for physical and chemical indicators such as content, acid value, and peroxide value, and prepared for treatment.

[0025] 2. Carry out ethyl esterification to perilla oil:

[0026] (1) Put 1000 kg of perilla oil into the esterification tank, and then add 350 kg of absolute ethanol (C 2 h 5 OH) and 4 kg of sodium ethoxide solution (C 2 h 5 ONa) was used as a catalyst, the temperature was heated to 78°C, and the reaction was carried out for 0.5 hours;

[0027] (2) After the reaction is over, add about 40 kg of water to deactivate the catalyst;

[0028] (3) Collect the products after esterification, including fatty acid ethyl ester, excess ethanol, water, glycerin and other mixtures;

[0029] 3. One-time purification by short-path distillation: send the esterified product to the short-path distillation equipment unit, and distill through the secondary thin-film evapora...

Embodiment 2

[0033] 1. Detection and pretreatment: The purchased linseed oil (α-linolenic acid content ≥ 52%) is tested for physical and chemical indicators such as content, acid value, and peroxide value, and prepared for processing.

[0034] 2. Ethylating linseed oil:

[0035] (1) Put 1000 kg of linseed oil into the esterification tank, and then add 350 kg of absolute ethanol (C 2 h 5 OH) and 4 kg of sodium ethoxide solution (C 2 h 5 ONa) was used as a catalyst, the temperature was heated to 78°C, and the reaction was carried out for 0.5 hours;

[0036] (2) After the reaction is over, add about 40 kg of water to deactivate the catalyst;

[0037] (3) Collect the products after esterification, including fatty acid ethyl ester, excess ethanol, water, glycerin and other mixtures;

[0038] 3. One-time purification by short-path distillation: send the esterified product to the short-path distillation equipment unit, and distill through the secondary thin-film evaporator (control the tempe...

Embodiment 3

[0042] 1. Detection and pretreatment: The purchased peony seed oil (α-linolenic acid content ≥ 42%) is tested for physical and chemical indicators such as content, acid value, and peroxide value, and prepared for processing.

[0043] 2. Carry out ethyl esterification to peony seed oil:

[0044] (1) Put 1000 kg of peony seed oil into the esterification tank, and then add 350 kg of absolute ethanol (C 2 h 5 OH) and 4 kg of sodium ethoxide solution (C 2 h 5 ONa) was used as a catalyst, the temperature was heated to 78°C, and the reaction was carried out for 0.5 hours;

[0045] (2) After the reaction is over, add about 40 kg of water to deactivate the catalyst;

[0046] (3) Collect the products after esterification, including fatty acid ethyl ester, excess ethanol, water, glycerin and other mixtures;

[0047] 3. One-time purification by short-path distillation: send the esterified product to the short-path distillation equipment unit, and distill through the secondary thin-film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com