Flame-retardant silk and its preparation method and application

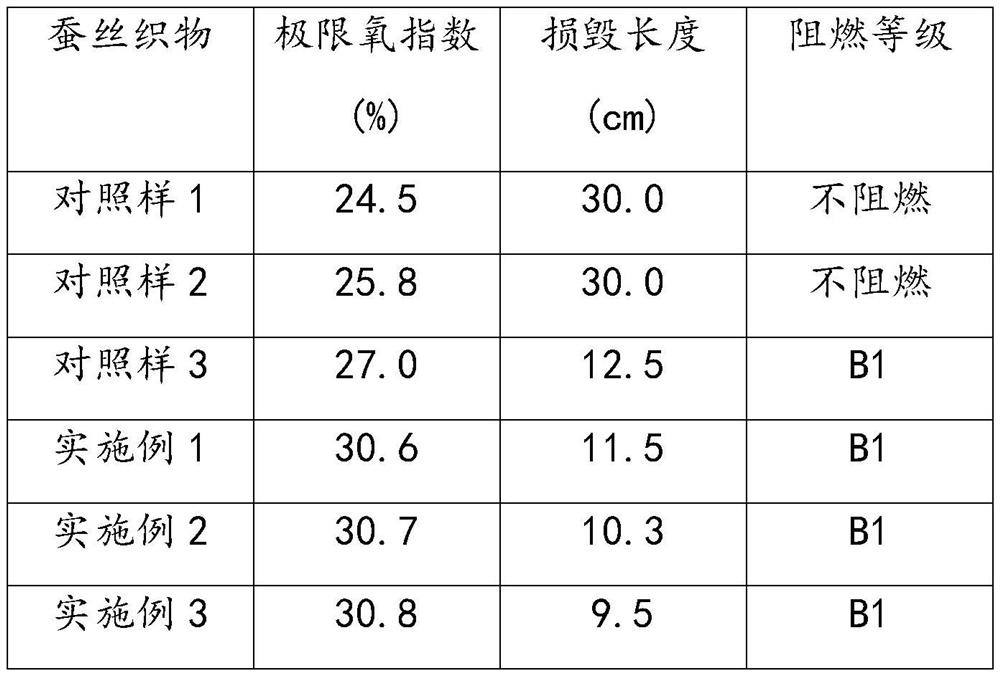

A technology of silk and yam, applied in flame-retardant fibers, textiles, papermaking, animal fibers, etc., can solve the problems of poor washing durability, limited increase in the limit oxygen index of flame-retardant silk fabrics, and inability to achieve. Guarantee the effect of washing durability, good durability and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] S1. Preparation of Ranunculus yam extract and modification of silk fabric with the extract of Ranunculus yam:

[0021] Wash the yam tubers, peel and chop them. Weigh 150g of chopped yam tubers, add 500mL of water, grind and beat mechanically, adjust the pH value of the slurry to 8 with soda ash, heat to 85°C, soak for 80min, then stand, cool, and filter; add water to dilute the filtrate, Stir evenly and set the volume to 1L to obtain the Ranunculus yam extract. Through the above steps, the tannin condensation in the potato can be extracted, and the tannin condensation is dissolved in water.

[0022] The amount of the above-mentioned Ranunculus yam extract and silk was configured according to the bath ratio of 1:50. The silk was immersed in the extract of Ranunculus yam, and the treatment started at 30°C, and the temperature was gradually raised to 90°C at a heating rate of 2°C / min, and the temperature was kept for 70 minutes. After the soaking treatment, the silk is ...

Embodiment 2

[0027] S1. Wash, peel and chop the tubers of Ranunculus yam. Weigh 75g of chopped yam tubers, add 500mL of water, mechanically pulverize and beat, adjust the pH value of the slurry to 8 with soda ash, heat to 95°C, soak for 50min, then stand, cool, and filter; add water to dilute the filtrate, Stir evenly and set the volume to 1L to obtain the Ranunculus yam extract. The amount of the above-mentioned Ranunculus yam extract and silk was configured according to the bath ratio of 1:50. The silk was immersed in the extract of Ranunculus yam, and the treatment started at 30°C, and the temperature was gradually raised to 75°C at a heating rate of 2°C / min, and the heat preservation treatment was carried out for 120 minutes. After the soaking treatment, the silk is taken out and washed with water to obtain the silk fabric modified by the yam extract.

[0028] S2. Prepare a solution of second-generation polypropyleneimine dendrimers (molecular weight: 777 g / mol) at a concentration of...

Embodiment 3

[0030] S1. Wash, peel and chop the tubers of Ranunculus yam. Weigh 125g of chopped yam tubers, add 500mL of water, mechanically pulverize and beat, adjust the pH value of the slurry to 8 with soda ash, heat to 90°C, soak for 65min, then stand, cool, and filter; add water to the filtrate to dilute , stir evenly, and set the volume to 1L to obtain the Ranunculus yam extract. Prepare the silk and polypropyleneimine dendrimers solution at a liquor ratio of 1:50. Immerse the silk in the extract of Ranunculus yam, start treatment at 30°C, gradually raise the temperature to 85°C at a heating rate of 2°C / min, and keep it warm for 90 minutes. After the soaking treatment, the silk is taken out and washed with water to obtain the silk fabric modified by the yam extract.

[0031] S2. Prepare a 15 g / L solution of second-generation polypropyleneimine dendrimers (molecular weight: 777 g / mol), and adjust the pH of the solution to 8.5 with acetic acid and soda ash to obtain a solution of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com