Zero-carbon emission three-cycle integral coal gasification fuel cell electricity generation system and method

An integrated coal gasification and fuel cell technology, applied in fuel cells, electrochemical generators, combustible gas purification, etc., can solve the problems of ultra-supercritical coal-fired power generation units and IGCCs that are difficult to achieve carbon emission targets, and achieve the avoidance of calorific value Significantly reduce and simplify the power generation system process and improve the effect of net power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

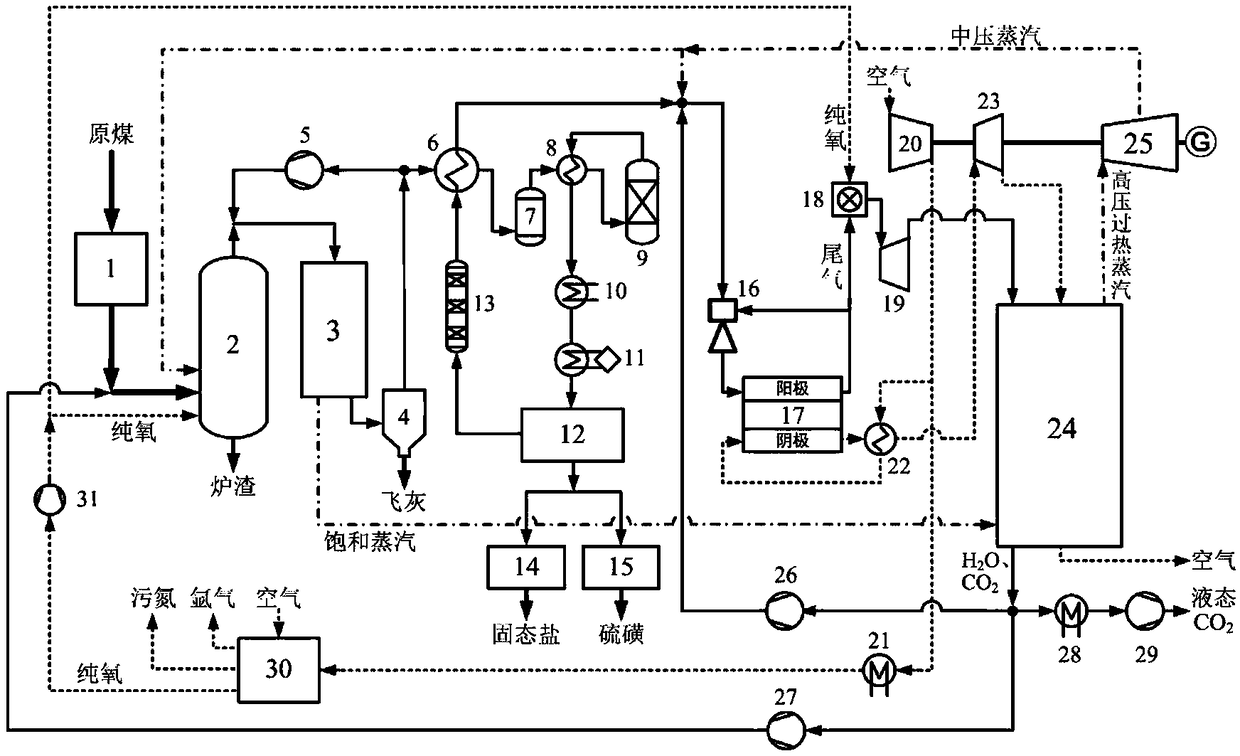

[0037] Such as figure 1 As shown, a three-cycle integral coal gasification fuel cell power generation system with zero carbon emission provided by the present invention includes a coal preparation unit 1, a gasification furnace 2, a waste heat boiler 3, a dust removal unit 4, a circulating gas compressor 5, a first Gas heater 6, water washing tower 7, second gas heater 8, carbonyl sulfide hydrolysis reactor 9, waste heat recovery unit 10, syngas cooler 11, desulfurization unit 12, humidifier 13, water treatment unit 14, Sulfur recovery unit 15, ejector 16, fuel cell 17, pure oxygen burner 18, gas turbine 19, air compressor 20, first heat recovery heat exchanger 21, cathode regenerator 22, air turbine 23, waste heat boiler 24, steam turbine 25, first carbon dioxide compressor 26, second carbon dioxide compressor 27, second waste heat recovery heat exchanger 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com