Bone tissue repair ink, composition and bracket, and preparation methods thereof as well as kit

A technology of bone tissue and composition, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of easy loss of cell characteristic protein expression, affecting cell growth, etc., and achieve easy loss, good growth environment, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

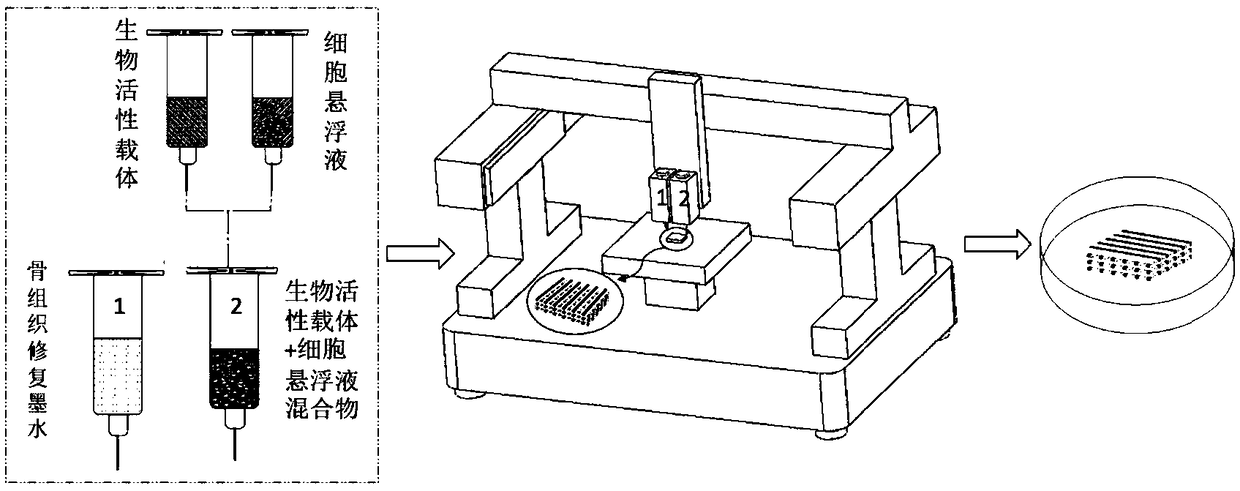

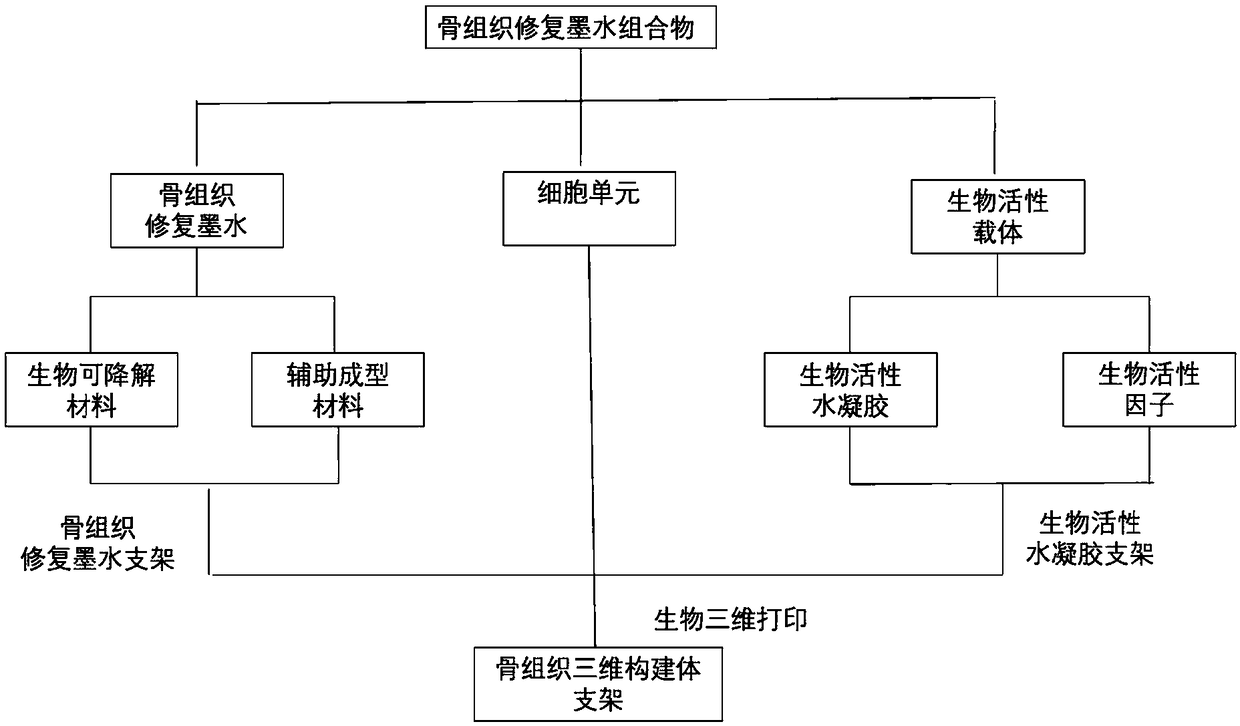

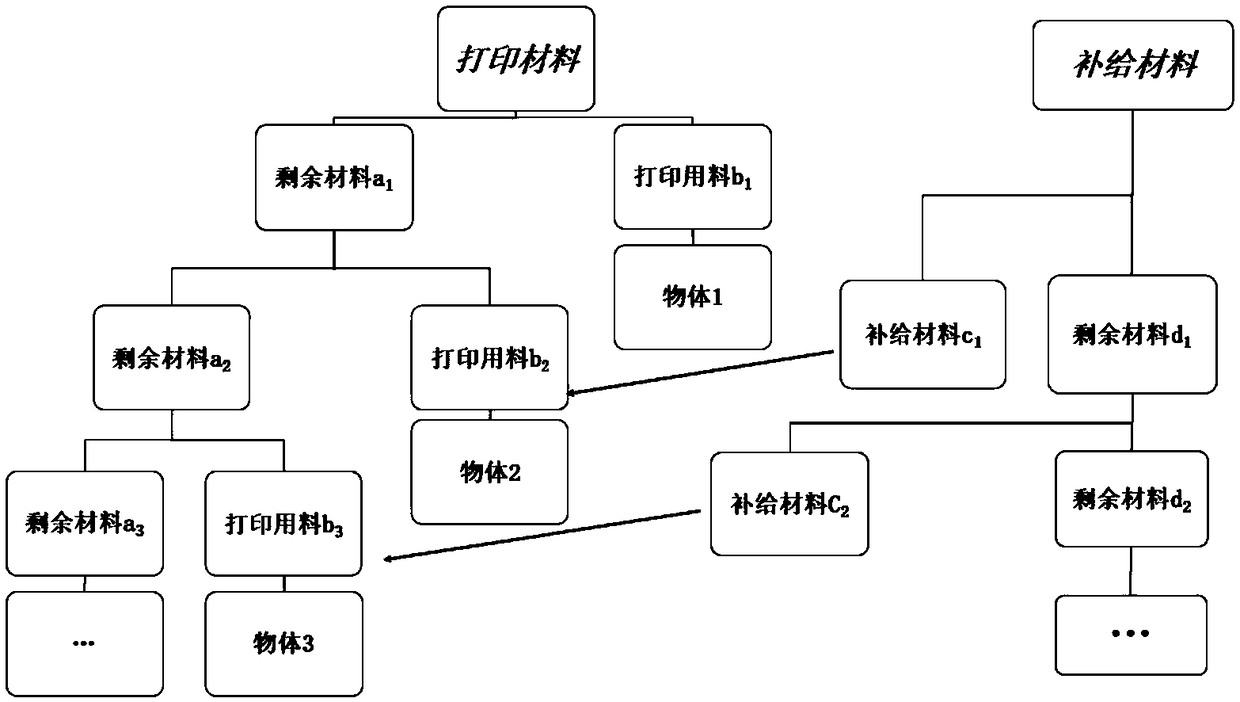

Method used

Image

Examples

preparation example Construction

[0048] Some embodiments of the present invention provide a method for preparing bone tissue repair ink, the steps of which are as follows:

[0049] (1) A mixture of one or more biodegradable materials is provided.

[0050] (2) A mixture of one or more auxiliary molding materials is provided.

[0051] (3) Select a material formula 1 from one or more biodegradable materials in step (1), select a formula 2 from one or more auxiliary molding materials in step (2), and combine formulas 1 and 2 Slurry to form bone tissue repair ink.

[0052] Further, the biodegradable material in the bone tissue repair ink is hydroxyapatite or tricalcium phosphate, and the mass ratio of hydroxyapatite and tricalcium phosphate in the bone tissue repair ink is about 0:10-10:0 , such as 0:10, 1:9, 2:8, 3:7, 4:6, 5:5, 6:4, 7:3, 8:2, 9:1, 10:0. The mass percentage of the mixture of hydroxyapatite and tricalcium phosphate in the bone tissue repairing ink is 50%-80%. In some preferred embodiments, the ...

Embodiment 1

[0132] This embodiment provides a scaffold for bone tissue repair, which is prepared according to the following steps:

[0133] (1) The mixed powder of β-tricalcium phosphate (β-TCP) and hydroxyapatite (HAP) with a mass ratio of 7:3 is used as a raw material, and a mixture of deionized water and glycerol (a volume ratio of 6: 4) is used as a solvent, sodium polyacrylate is used as a dispersant, and a vacuum defoaming machine is used for gradient centrifugal stirring for 1 h (the maximum speed is set at 3000 rpm) to prepare a slurry with a solid phase content of 38 vol%. Add collagen to the slurry as a bio-adhesive, the addition is 1wt% of the mixed powder, use a vacuum defoamer to mix for 2 hours, and use ultrasonic vibration (frequency 100Hz, time 30min, temperature 30°C), low temperature defoaming ( time 12h, temperature 4°C), to obtain bioactive ceramic slurry, the viscosity of the slurry is lower than 100Pa·S, and the solidification time in air is less than 1min.

[0134]...

Embodiment 2

[0137] This embodiment provides a scaffold for bone tissue repair, which is prepared according to the following steps:

[0138] (1) The mixed powder of β-tricalcium phosphate (β-TCP) and hydroxyapatite (HAP) with a mass ratio of 7:3 is used as a raw material, and a mixture of deionized water and glycerol (a volume ratio of 6: 4) is used as a solvent, sodium polyacrylate is used as a dispersant, and a vacuum defoaming machine is used for gradient centrifugal stirring for 1 h (the maximum speed is set at 3000 rpm) to prepare a slurry with a solid phase content of 38 vol%. Sodium alginate was added to the slurry as a bio-binder in an amount of 0.8wt% of the mixed powder, mixed for 2 hours using a vacuum defoamer, and degassed by ultrasonic vibration (frequency 100Hz, time 30min, temperature 30°C) and low temperature. Bubble (time 12h, temperature 4°C) to obtain bioactive ceramic slurry, the viscosity of the slurry is lower than 100Pa·S, and the solidification time in air is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Solidification time | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com