Catalyst for propane dehydrogenation and preparation method thereof, and method for preparing propylene from propane through dehydrogenation

A propane dehydrogenation and catalyst technology, applied in catalyst activation/preparation, catalyst, molecular sieve catalyst, etc., can solve the problems of low selectivity of propane dehydrogenation active propylene, small pore size and pore volume, unstable mesoporous structure, etc. Achieve the effect of low preparation cost, simple preparation process and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] The present invention has no particular limitation on the conditions of the mixing and contacting, for example, the conditions of the mixing and contacting may include: a temperature of 25-60° C., a time of 10-72 hours, and a pH value of 1-7. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0044] In the present invention, the crystallization conditions are not particularly limited. For example, the crystallization conditions may include: a temperature of 30-150°C, preferably 90-150°C; a time of 10-72h, preferably 10 -40h. According to a preferred embodiment, the crystallization is carried out by hydrothermal crystallization.

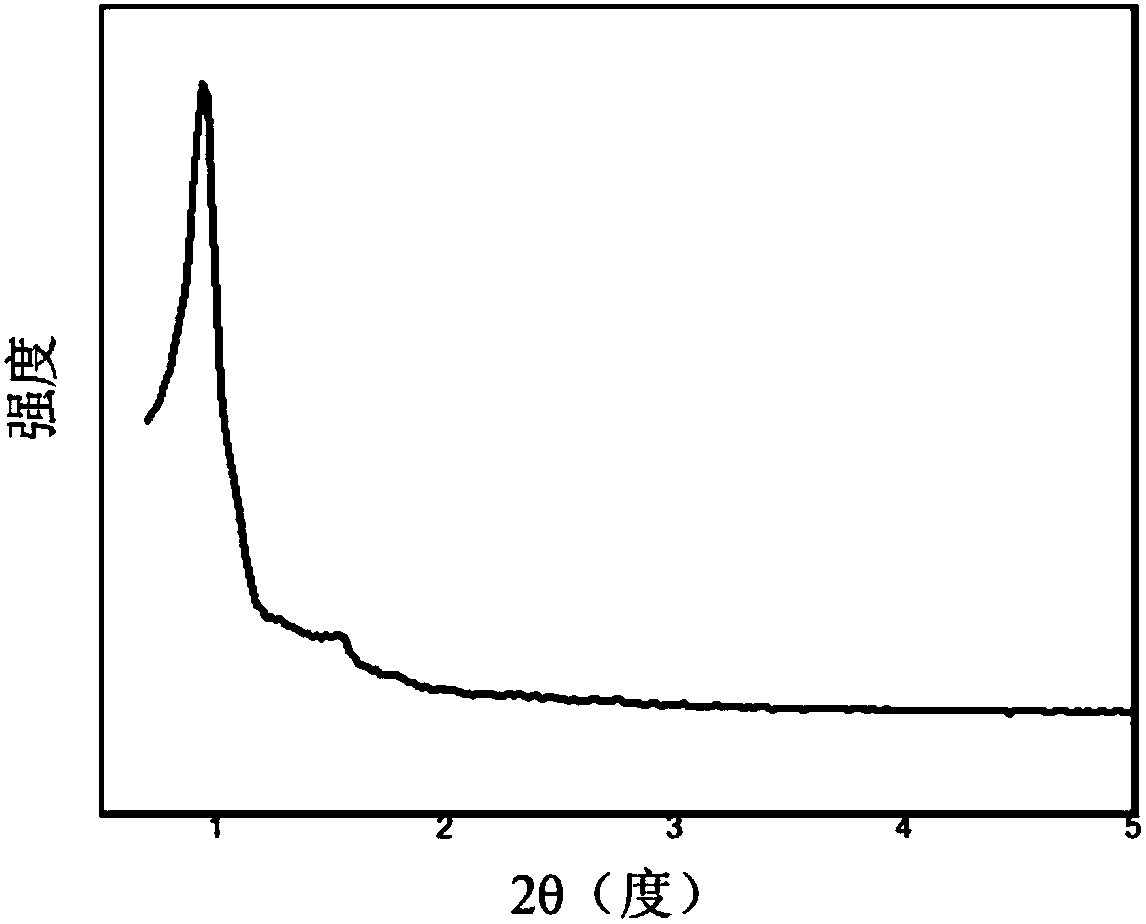

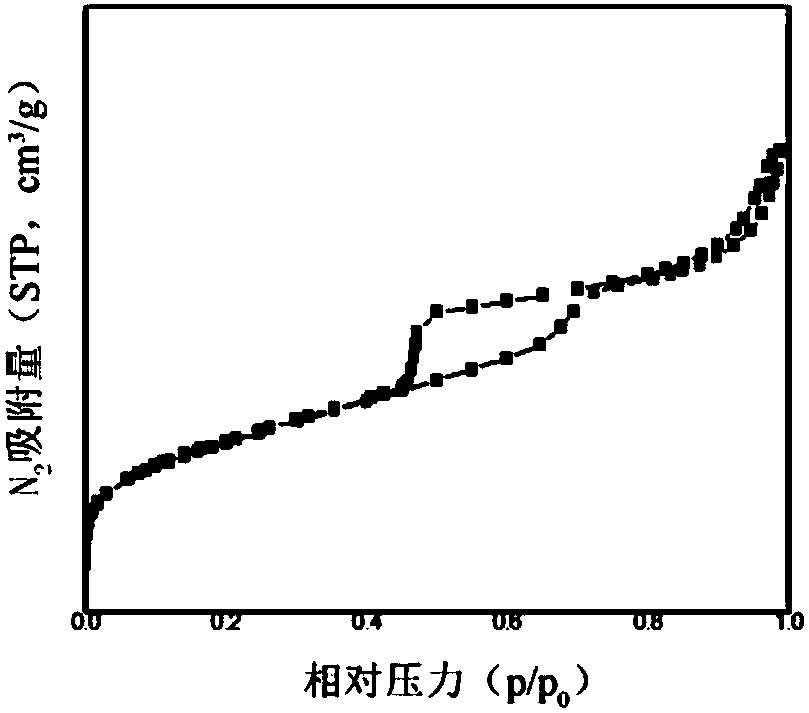

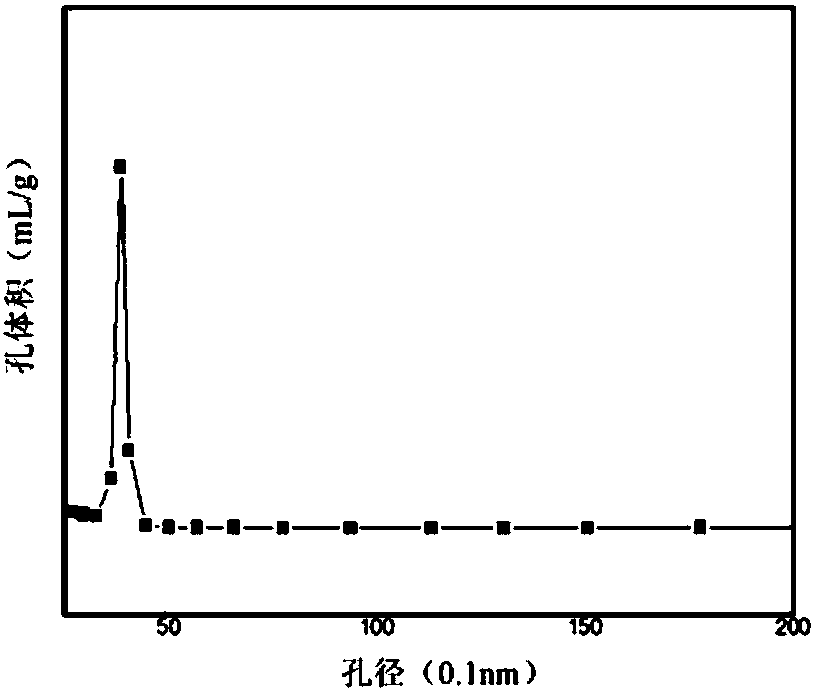

[0045] In the present invention, in the above-mentioned process of preparing the hexagonal mesoporous material, the process of obtaining the raw powder of the hexagonal mesoporous material ...

Embodiment 1

[0057] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0058] (1) Preparation of carrier

[0059] 2g (1.4×10 -4mol) template agent F108, 5.24g (0.03mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0060] Add 4.2g (0.02mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, and stand at 38°C for 24h;

[0061] Then it was transferred to an agate-lined reactor, crystallized at 100°C for 24 hours, then filtered and washed 4 times with deionized water, and then suction filtered to obtain the raw powder cake of hexagonal mesoporous materials;

[0062] The 30g hexagonal mesoporous material raw powder filter cake obtained by the above-mentioned suction filtration is put into a 100ml ball mill jar, wherein, the material of the ball mill jar is polytetrafluoroethylene, the material of the ball mill is agate, the diameter o...

Embodiment 2

[0091] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

[0092] (1) Preparation of carrier

[0093] 1.46g (1×10 -4 mol) template agent F108, 6.96g (0.04mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0094] Add 3.1g (0.015mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, and stand at 38°C for 24h;

[0095] Then transfer it to an agate-lined reaction kettle, crystallize at 120°C for 30h, then filter and wash 4 times with deionized water, and then suction filter to obtain the original powder cake of hexagonal mesoporous material;

[0096] The 30g hexagonal mesoporous material raw powder filter cake obtained by the above-mentioned suction filtration is put into a 100ml ball mill jar, wherein, the material of the ball mill jar is polytetrafluoroethylene, the material of the ball mill is agate, the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com