Semi-coke high-concentration organic wastewater resource treatment system and method

An organic waste water and treatment method technology, applied in the field of water treatment, can solve the problems of harshness, high operating costs, harsh reaction conditions, etc., and achieve the effects of high-efficiency and low-consumption recovery, reducing operating costs, and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will now be further described in conjunction with the drawings and embodiments, but the present invention is not limited to the following implementation situations.

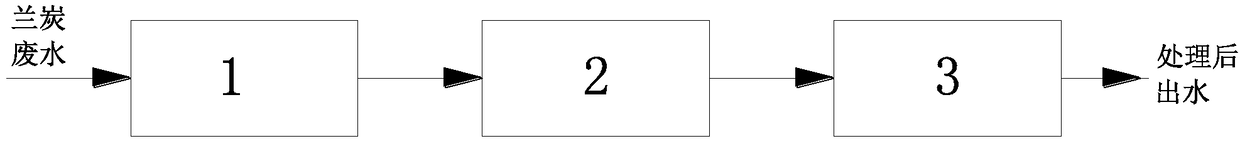

[0045] see figure 1 , the semi-coke high-concentration organic wastewater resource treatment system of this embodiment includes a pretreatment unit 1, a distilled amino-extraction treatment unit 2 and a fine filtration adsorption treatment unit 3 connected in sequence;

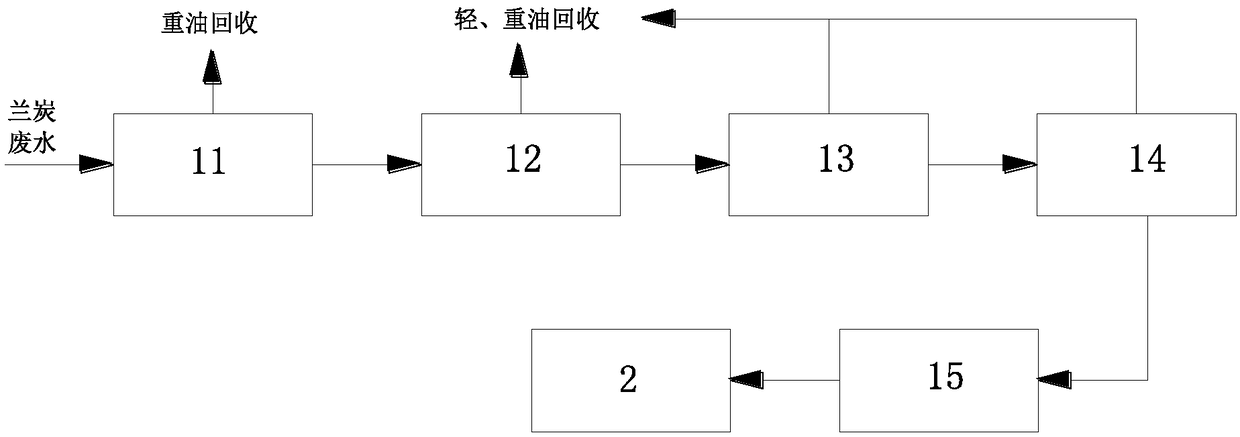

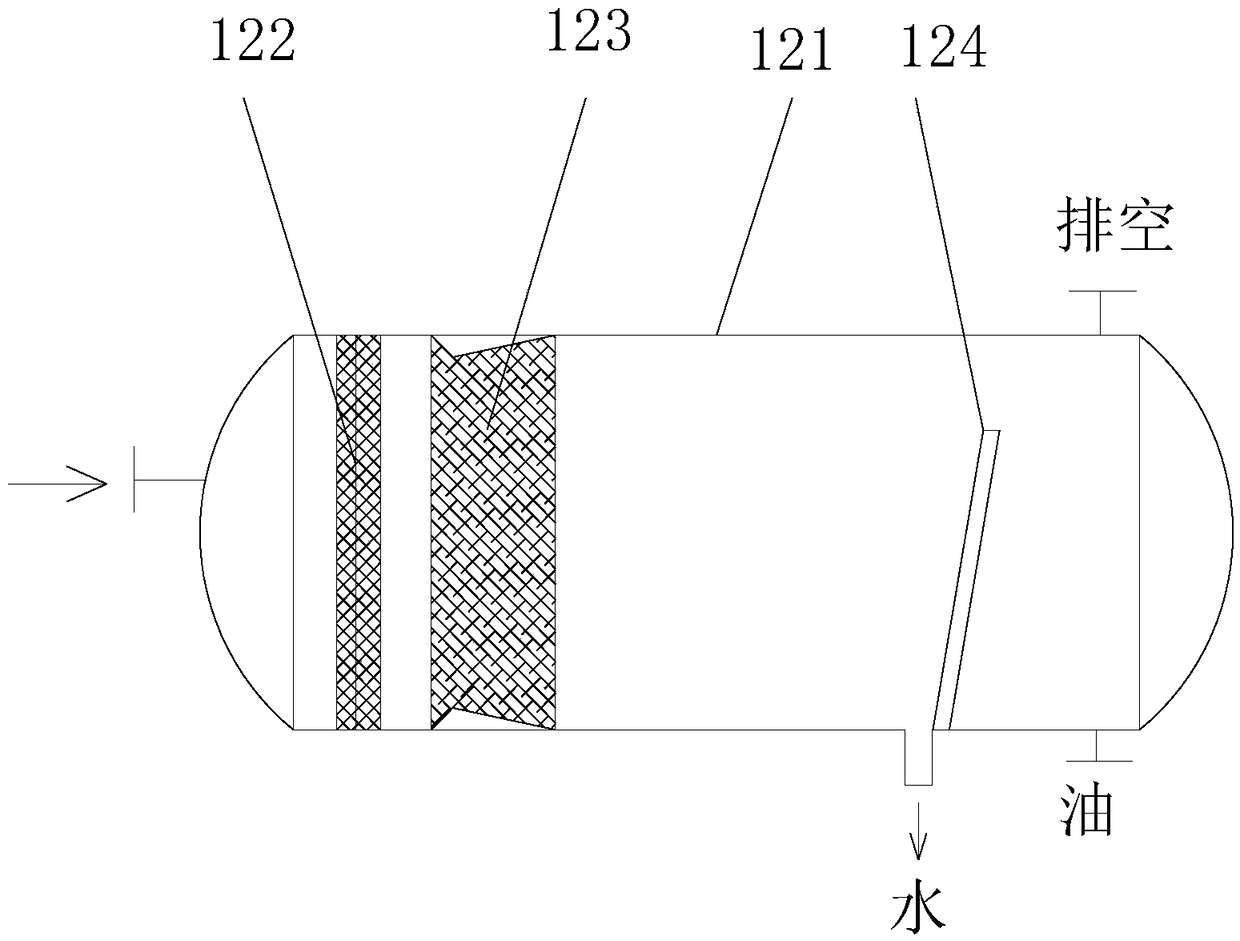

[0046] Preprocessing unit 1, see figure 2 , including a sequentially connected pretreatment device 11, a multiphase flow separator 12, a coagulation device 13, a dual-media filter 14, and a primary fine filter 15, wherein the pretreatment device 11 mainly removes oil residue and a small amount of heavy coal in waste water Tar oil is pre-separated. The pretreated oil-water mixture enters the high-efficiency multiphase flow separator 12 . see image 3 , the multiphase flow separator 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com