A kind of soft foundation material prepared by solidification of silt and its preparation method

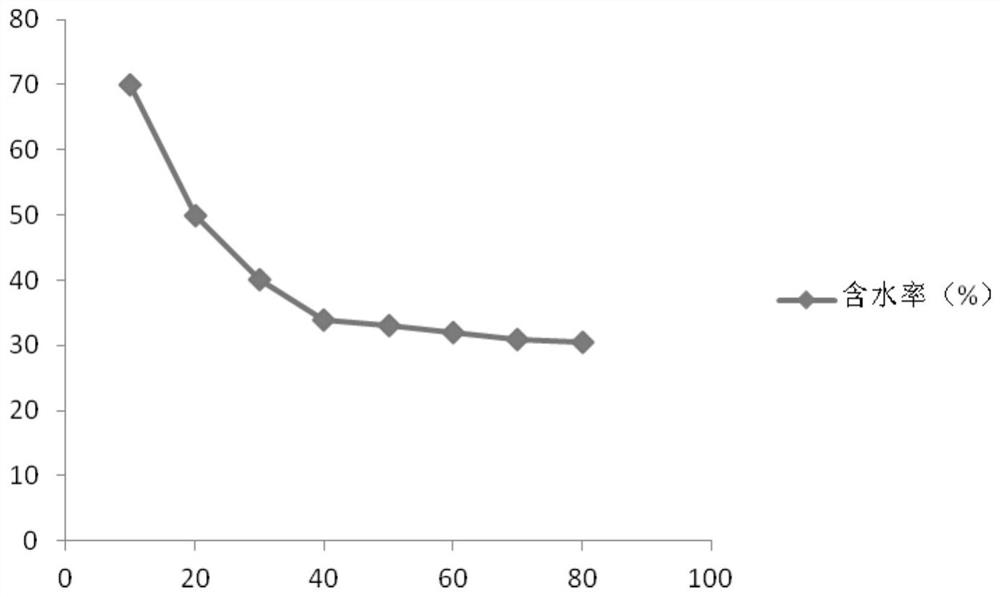

A soft foundation and silt technology, applied in the field of soft foundation materials and its preparation, can solve the problems of low strength, long curing time, poor permeability, etc., achieve strong water absorption, improve silt characteristics, and unique dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

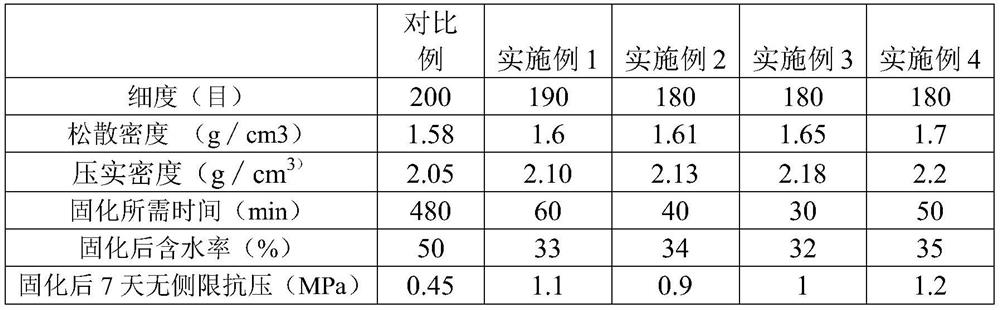

Examples

Embodiment 1

[0032] A method for preparing soft foundation materials by solidifying silt, the specific steps are as follows:

[0033] (1) Choose Bayer method or sintering method red mud, adjust its water content to 22%, and grind or crush it to a powder with a particle size of 200-300 mesh;

[0034] (2) aging phosphogypsum for 5 days to obtain material A; calcining material A at 250° C. for 1 hour to obtain material B, and then cooling the material B naturally; mixing the material A and material B according to 90%:10 % by weight ratio and mixed evenly, and the particle size is 200-300 mesh powder, that is, modified phosphogypsum;

[0035](3) according to the material preparation sludge curing agent of following percentage by weight: modified diatomite 26%, attapulgite 38%, magnesium oxide 14%, calcium chloride 3%, potassium permanganate 1%, sodium peroxide 7% %, cationic chelate 1%, sodium hypochlorite 2%, sodium lauryl sulfate 0.5%, polyoxyethylene-polyoxypropylene copolymer 2%, chitosan...

Embodiment 2

[0038] A method for preparing soft foundation materials by solidifying silt, the specific steps are as follows:

[0039] (1) Choose Bayer method or sintering method red mud, adjust its water content to 24%, and grind or pulverize it to a powder with a particle size of 200-300 mesh;

[0040] (2) Aging phosphogypsum for more than 7 days to obtain material A; calcining material A at 230° C. for 2.5 hours to obtain material B, and then naturally cooling the material B; the material A and material B according to 92%: 8% by weight ratio is uniformly mixed, and the particle size is 200-300 mesh powder, that is, modified phosphogypsum;

[0041] (3) according to the material preparation sludge curing agent of following percentage by weight: modified diatomite 30%, attapulgite 30%, magnesium oxide 10%, calcium chloride 4%, potassium permanganate 3%, calcium peroxide 10% %, strontium peroxide 2%, cationic chelate 2%, sodium hypochlorite 1%, isothiazolinone 0.5%, sodium lauryl sulfate 0....

Embodiment 3

[0044] A method for preparing soft foundation materials by solidifying silt, the specific steps are as follows:

[0045] (1) Choose Bayer method or sintering method red mud, adjust its water content to 25%, and grind or crush it to a powder with a particle size of 200-300 mesh;

[0046] (2) Aging phosphogypsum for more than 8 days to obtain material A; calcining material A at 210° C. for 2 hours to obtain material B, and then naturally cooling the material B; 7% by weight ratio is obtained by mixing evenly, and the particle size is 200-300 mesh powder, that is, modified phosphogypsum;

[0047] (3) according to the material preparation sludge curing agent of following percentage by weight: modified diatomite 35%, attapulgite 25%, magnesium oxide 15%, calcium chloride 4%, potassium permanganate 1%, magnesium peroxide 6 %, zinc peroxide 6%, cationic chelate 1%, sodium hypochlorite 1%, isothiazolinone 0.2%, sodium lauryl sulfate 0.1%, polyoxyethylene-polyoxypropylene copolymer 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com