Heavy metal passivating and nitrogen-preserving method in livestock manure aerobic composting process

A technology of livestock and poultry manure and aerobic composting, which is applied in the field of resource utilization of livestock and poultry manure, can solve the problems of reducing effectiveness and achieve the effects of improving holding capacity, reducing odorous gas emissions, and reducing the bioavailability of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of conditioner: crush corn stalks with a moisture content of less than 15% into small sections of 2-5 cm in length, and use them as compost conditioners to prepare biochar, specifically, heat them in a muffle furnace at 600°C under anaerobic conditions. After 2 hours of solution, the heating rate from room temperature to 600°C was 15°C / min, and the obtained biochar was crushed into powders smaller than 1mm.

[0031] The heavy metal passivation material is modified, biochar and phosphate rock powder are placed in hydrochloric acid solution for modification, the volume ratio of passivation material precursor to hydrochloric acid solution is 1:2, and the concentration of hydrochloric acid is 1mol / L, so that Completely soak, vibrate at 180rpm for 1 hour, then let it stand and soak for 1 day, take out the biochar and phosphate rock powder and filter it, then place it in the organic solvent acetone, and add the heavy metal passivation material in a volume ratio of ...

Embodiment 2

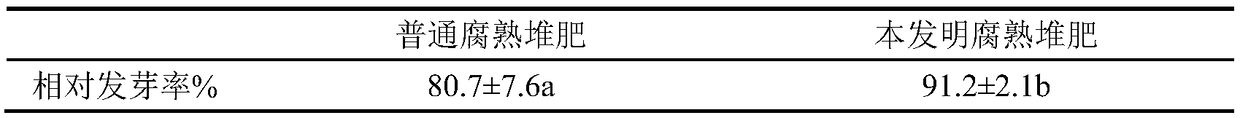

[0034] The compost after the aerobic compost of the present invention is decomposed according to the embodiment 1 is subjected to a seed germination test. Ordinary compost is: 100 parts by weight of pig manure and 30 parts by weight of corn stalks as conditioners, crushed corn stalks into 2-5cm long pieces, adjusted the carbon-nitrogen ratio to 28, and the weight moisture content to 60%, fully mixed for aerobic composting Compost, turn the pile with natural ventilation, turn the pile once every 4 days, carry out ventilation and turn the pile, and add water to keep the moisture content of the manure pile at 60%, turn the pile 9 times in total, when the temperature gradually decreases to slightly higher than the ambient temperature by 5°C When the manure pile is compacted, an anaerobic environment inside the pile is formed, and the compost will be decomposed after 35 days. Utilize decomposed compost of the present invention and common decomposed compost to carry out germination ...

Embodiment 3

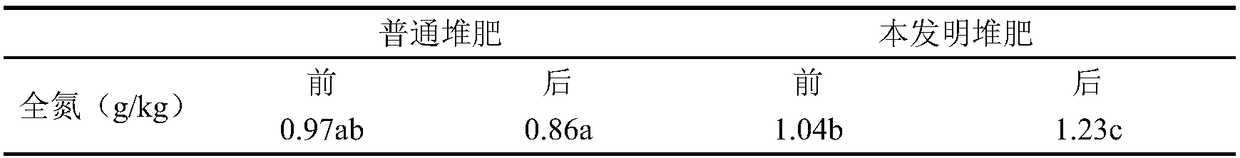

[0040] According to the aerobic compost of the present invention in Examples 1 and 2, the decomposed product and the common decomposed compost were subjected to the determination of the total nitrogen content. The measurement index is sampling and measuring the total nitrogen content before and after composting, and Table 2 shows the total nitrogen content of common compost and compost of the present invention before and after decomposing.

[0041] Table 2 Comparison table of changes in total nitrogen content before and after composting of the present invention and common composting

[0042]

[0043] Note: Different lowercase letters indicate significant differences at the 0.05 level, n=3

[0044] The change of total nitrogen content before and after common decomposing composting shows that the nitrogen content of organic manure formed by common composting is less than that before composting, which is mainly caused by the large loss of nitrogen during composting (Table 2). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com