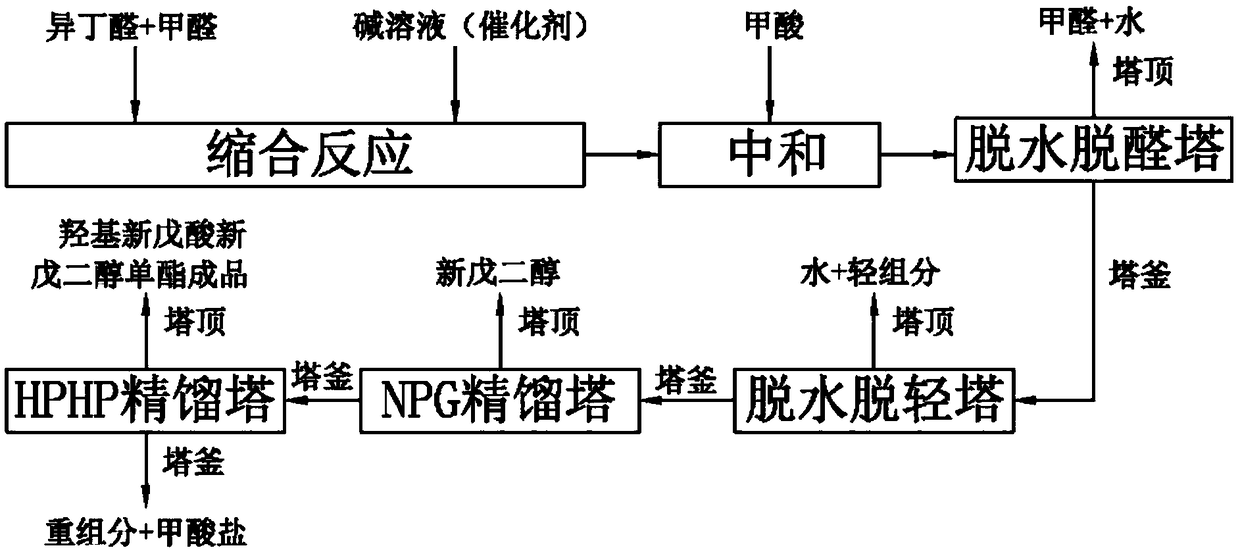

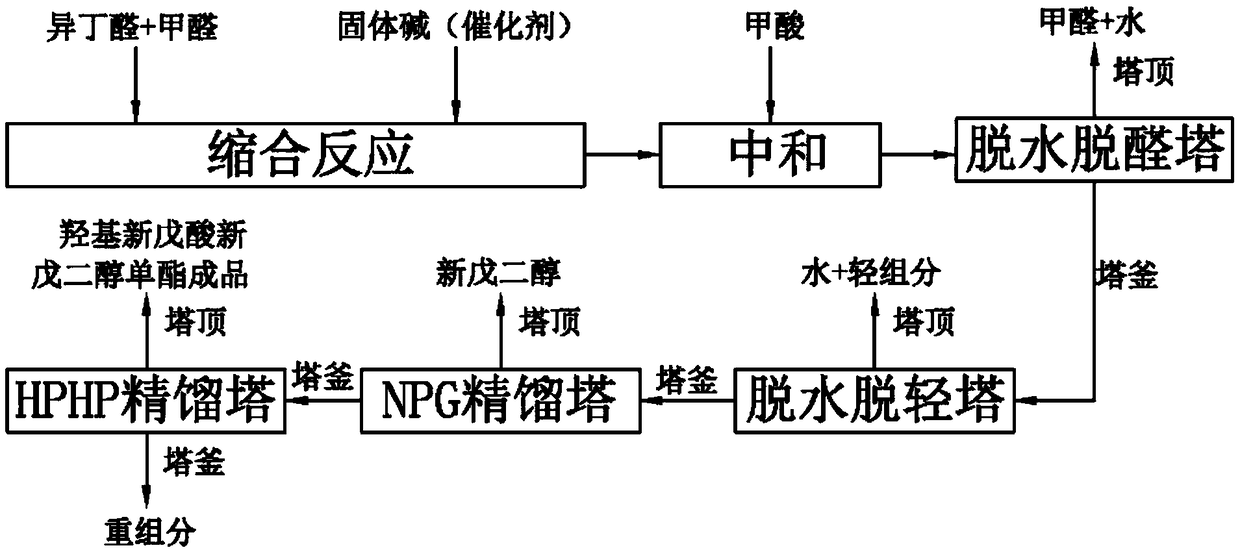

Preparation method of combined production of hydroxyl neopentanoic acid neopentyl glycol monoester and neopentyl glycol

A technology of hydroxypivalic acid neopentyl glycol monoester and neopentyl glycol is applied in the field of preparation of hydroxypivalic acid neopentyl glycol monoester and neopentyl glycol co-production, and can solve the problem that there is no hydroxy neopentyl glycol yet. Acid neopentyl glycol monoester and neopentyl glycol and other problems, to achieve the effect of less equipment investment, high product purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

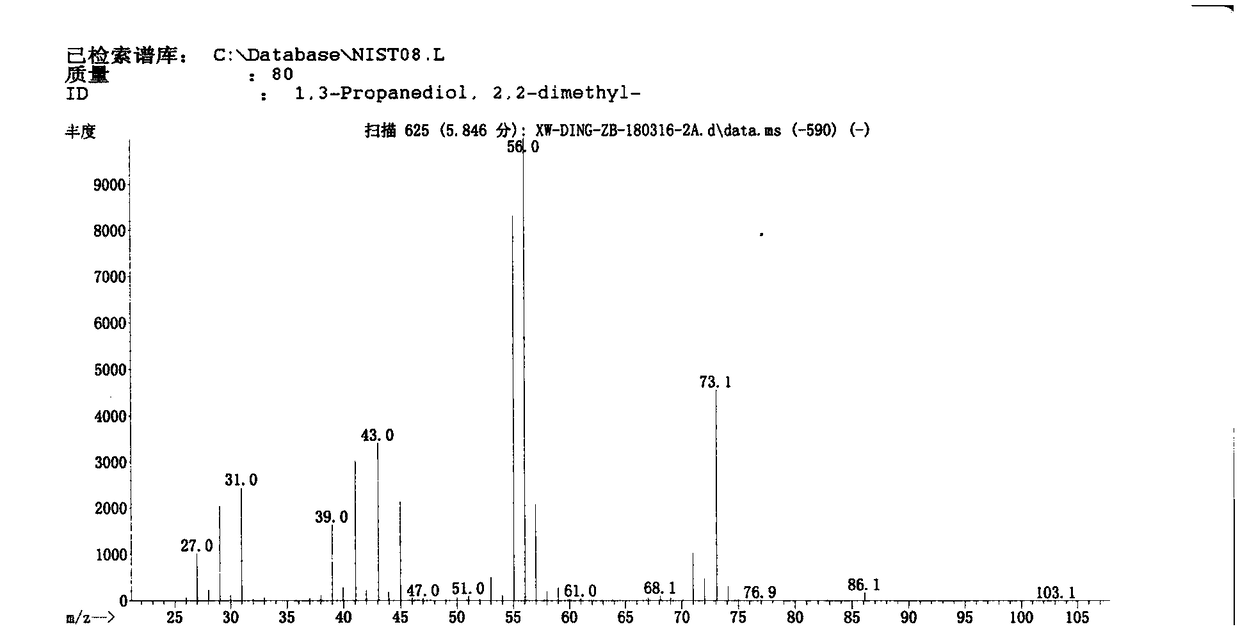

[0040] According to isobutyraldehyde: formaldehyde molar ratio = 1:1.75, put in isobutyraldehyde with a concentration of about 99% and formaldehyde with a concentration of about 37%, add deionized water 15 times the weight of isobutyraldehyde, keep the temperature of the material at 30°C, and add mass The concentration is 15% sodium hydroxide solution to control the pH value = 10.5; start the reactor to stir, and react at a constant temperature for 5 hours; stop adding the sodium hydroxide solution, raise the temperature to 60°C and keep the temperature constant for 1 hour, and neutralize with formic acid to pH = 6.8- 6.9; the condensation liquid passes through the dehydration and dehydration tower (positive pressure operation, gauge pressure 0.2MPa) to remove water and formaldehyde; Components: Dehydration and delightening tower still material obtains neopentyl glycol product (mass spectrogram such as image 3Shown); NPG rectifying tower tower bottom material obtains hydroxy ...

Embodiment 2

[0042] According to the molar ratio of isobutyraldehyde: formaldehyde = 1:1.85, put in isobutyraldehyde with a concentration of about 99% and formaldehyde with a concentration of about 37%, add deionized water 10 times the weight of isobutyraldehyde, keep the temperature of the material at 30°C, and add mass The concentration is 15% sodium hydroxide solution to control the pH value = 9.5; start the reactor to stir, and react at a constant temperature for 5 hours; stop adding the sodium hydroxide solution, raise the temperature to 60°C and keep the temperature for 1 hour, and neutralize with formic acid to pH = 6.8- 6.9; the condensation liquid passes through the dehydration and dehydration tower (positive pressure operation, gauge pressure 0.1MPa) to remove water and formaldehyde; Components; dehydration and lightening tower bottom material obtains neopentyl glycol product (mass spectrogram is consistent with embodiment 1, does not repeat to provide) through NPG rectification t...

Embodiment 3

[0044] Fill the fixed-bed reactor according to the ratio of isobutyraldehyde:basic group in the solid base=1:1.0, and the solid base adopts a quaternary ammonium group [N—(CH 3 ) 2 C 2 h 4 OH] anion exchange resin; according to isobutyraldehyde: formaldehyde molar ratio=1:1.85 drops into the isobutyraldehyde of concentration about 99% and the formaldehyde of concentration about 37%, add the deionized water of 10 times of isobutyraldehyde weight; Constant temperature to 35°C, turn on the circulation pump of the fixed bed reactor to circulate for 6 hours; take 1 hour to raise the temperature to 50°C at a constant speed and keep the temperature at 50°C for 1 hour; filter the condensation liquid so that it does not contain solid alkali catalyst; the condensation liquid is dehydrated and dealdehyded The column (positive pressure operation, gauge pressure 0.3MPa) removes water and formaldehyde; the material in the dehydration and light removal tower (negative pressure operation, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap