Nano-palladium/carbon nanotube-MXene composite and application thereof to nitro-aromatic-type explosive detection

A carbon nanotube and composite material technology, applied in the field of explosives detection, can solve the problems of easy oxidation, easy stacking, easy agglomeration, etc., and achieves the effects of good stability, good selectivity and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

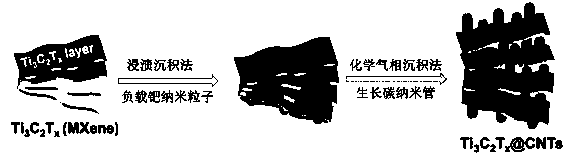

Method used

Image

Examples

Embodiment 1

[0037] 1. Add 3.0 g Ti 3 AlC 2 Added to 30 mL HF, stirred at a constant speed for 120 h under a constant temperature water bath at 35 ºC, washed the product with water until neutral and dried in vacuum to obtain multilayer Ti 3 C 2 T x MXene nanosheet material;

[0038] 2. Add 2.0 g of multi-layer MXene into 40 mL of DMSO, stir at a constant speed for 24 h at room temperature, centrifuge at 5000 rpm at high speed and disperse the lower sediment in 500 mL of ultrapure water, and ultrasonicate for 40 min in an ice bath in an ultrasonic cleaner. Low-speed centrifugation to take the upper layer and freeze-dry to obtain few-layer MXene nanosheets;

[0039] 3. Disperse 10 mg MXene in 30 mL ultrapure water, disperse evenly by ultrasonication for 30 min, and dissolve 2 mg K 2 PdCl 4 Added into the solution, stirred in ice bath for 3 h, centrifuged and freeze-dried to obtain Pd NPs / MXene composite material;

[0040] 4. Put the Pd NPs / MXene composite in a tube furnace, in an atm...

Embodiment 2

[0042] 1. Add 3.0 g Ti 3 AlC 2 Added to 30 mL HF, stirred at a constant speed for 120 h under a constant temperature water bath at 35 ºC, washed the product with water until neutral and dried in vacuum to obtain multilayer Ti 3 C 2 T x MXene nanosheet material;

[0043] 2. Add 2.0 g of multi-layer MXene into 40 mL of DMSO, stir at a constant speed for 24 h at room temperature, centrifuge at 5000 rpm at high speed and disperse the lower sediment in 500 mL of ultrapure water, and ultrasonicate for 40 min in an ice bath in an ultrasonic cleaner. Low-speed centrifugation to take the upper layer and freeze-dry to obtain few-layer MXene nanosheets;

[0044] 3. Disperse 10 mg MXene in 30 mL ultrapure water, disperse evenly by ultrasonication for 30 min, and dissolve 3 mg K 2 PdCl 4 Added into the solution, stirred in ice bath for 3 h, centrifuged and freeze-dried to obtain Pd NPs / MXene composite material;

[0045] 4. Put the Pd NPs / MXene composite in a tube furnace under Ar ...

Embodiment 3

[0047] 1. Add 3.0 g Ti 3 AlC 2 Added to 30 mL HF, stirred at a constant speed for 120 h under a constant temperature water bath at 35 ºC, washed the product with water until neutral and dried in vacuum to obtain multilayer Ti 3 C 2 T x MXene nanosheet material;

[0048] 2. Add 2.0 g of multi-layer MXene into 40 mL of DMSO, stir at a constant speed for 24 h at room temperature, centrifuge at 5000 rpm at high speed and disperse the lower sediment in 500 mL of ultrapure water, and ultrasonicate for 40 min in an ice bath in an ultrasonic cleaner. Low-speed centrifugation to take the upper layer and freeze-dry to obtain few-layer MXene nanosheets;

[0049] 3. Disperse 15 mg MXene in 30 mL ultrapure water, disperse evenly by ultrasonication for 30 min, and dissolve 2 mg K 2 PdCl 4 Added into the solution, stirred in ice bath for 3 h, centrifuged and freeze-dried to obtain Pd NPs / MXene composite material;

[0050] 4. Put the Pd NPs / MXene composite in a tube furnace under Ar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com