Phosphorus-doped bronze ore phase titanium dioxide nanowire array and preparation and application thereof

A nanowire array, titanium dioxide technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve the problems of poor conductivity, limit practical application, hinder capacity and rate performance, etc., to improve capacity and rate performance, The effect of enhancing surface reactivity and electron transport ability and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

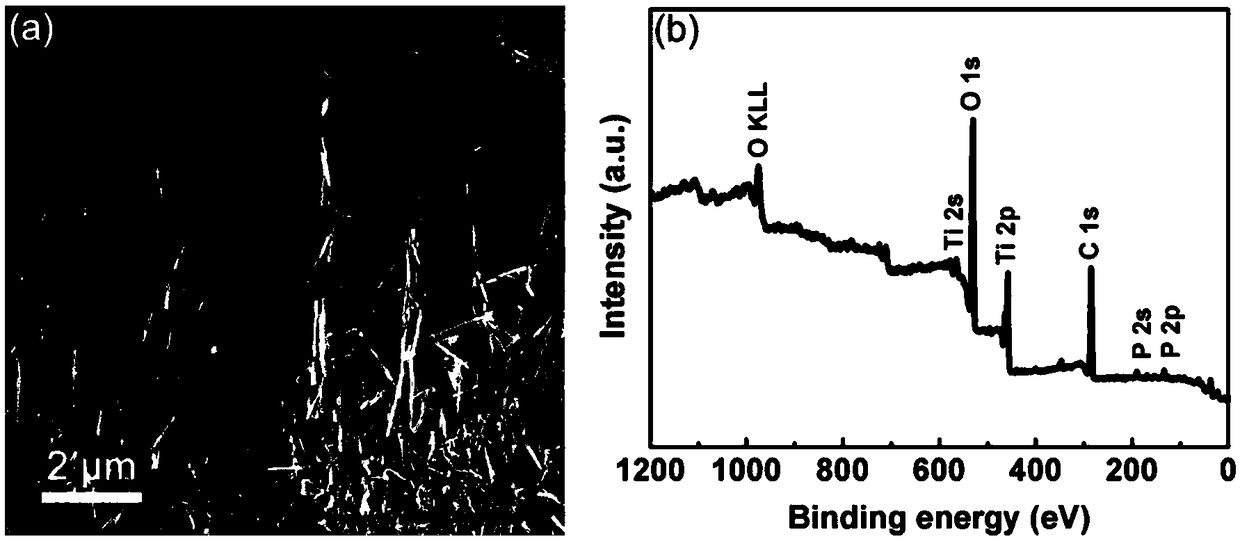

[0024] The preparation method of phosphor-doped bronze ore phase titanium dioxide nanowire array in the present invention is generally realized by a two-step method of hydrothermal growth and vapor phase doping, and may include the following specific steps:

[0025] (1) Put the clean titanium sheet into sodium hydroxide solution for a certain period of hydrothermal treatment, and grow the precursor sodium titanate nanowire array on the titanium sheet;

[0026] (2) Clean the hydrothermally treated titanium sheet and soak it in a hydrochloric acid solution so that the hydrogen ions in the solution completely replace the sodium ions in the sodium titanate, and then the titanium sheet is cleaned and dried;

[0027] (3) Put the dried titanium flakes and a certain amount of sodium hypophosphite into a ventilated tube furnace, the sodium hypophosphite is placed upstream of the air flow, and the titanium sheet is placed downstream of the air flow;

[0028] (4) In a protective atmosphere, heat ...

Embodiment 1

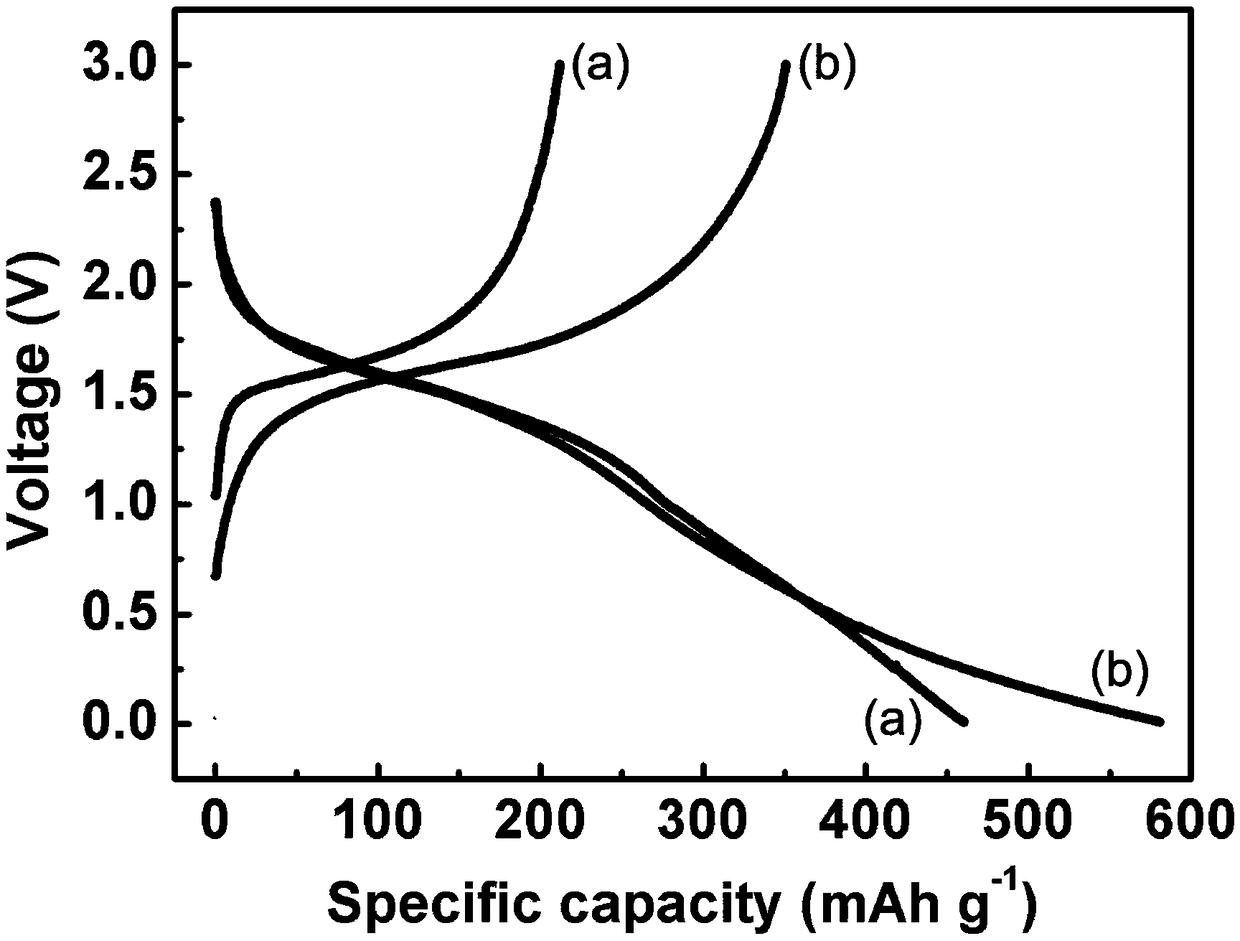

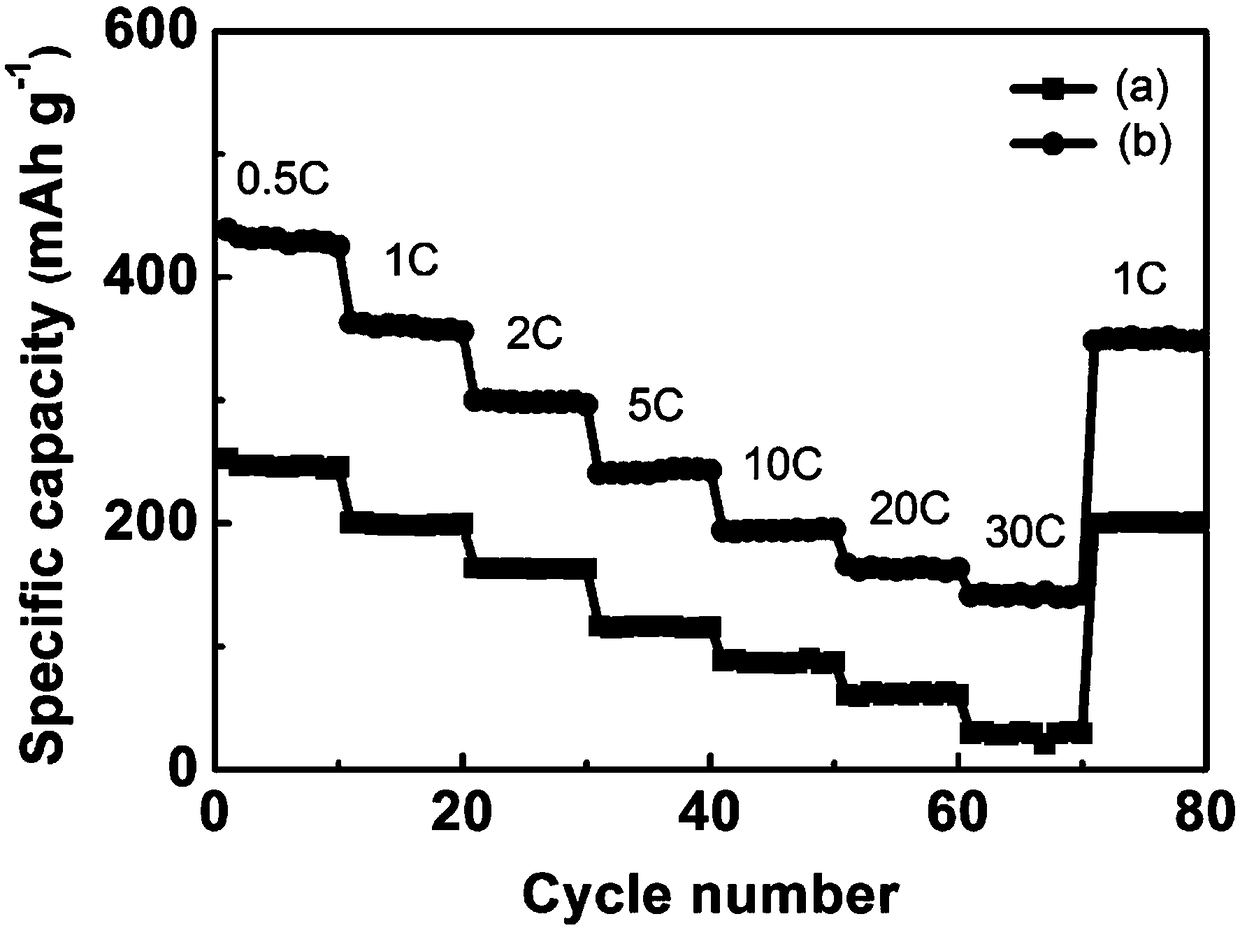

[0043] Put the clean titanium flakes into the inner lining of a hydrothermal kettle with a volume of 50 ml, then add 30 ml of sodium hydroxide solution with a concentration of 1 mole per liter to the inner lining, and then tighten the reaction kettle and place it at 220 Heat preservation for 3 hours in a high temperature electric furnace; after the reaction is completed, soak the washed titanium flakes in 1 mole per liter of hydrochloric acid solution for 30 minutes, then rinse and dry the titanium flakes; the dried titanium flakes and 0.5 g of sodium hypophosphite is placed in a tube furnace (sodium hypophosphite is upstream, titanium sheet is downstream), and under the protection of argon atmosphere, the temperature is raised to 300 degrees at 2 degrees per minute and kept for 4 hours. The preparation process is completed after reaching room temperature; a light blue film is formed on the titanium sheet, and the reversible capacity of the material is 230.5 mAh / g.

Embodiment 2

[0045] Put the clean titanium flakes into the inner lining of a hydrothermal kettle with a volume of 50 ml, then add 30 ml of sodium hydroxide solution with a concentration of 1 mole per liter to the inner lining, and then tighten the reaction kettle and place it at 220 Heat preservation for 12 hours in a high-temperature electronic furnace; after the reaction is complete, soak the washed titanium flakes in 1 mole per liter of hydrochloric acid solution for 30 minutes, then rinse and dry the titanium flakes; the dried titanium flakes and 0.5g of sodium hypophosphite is placed in a tube furnace (sodium hypophosphite is upstream and titanium sheet is downstream), under the protection of argon atmosphere, the temperature is increased to 400 degrees at 2 degrees per minute and kept for 3 hours. The preparation process is completed after reaching room temperature; a light blue film is formed on the titanium sheet, and the reversible capacity of the material reaches 278.3 mAh per gram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com