High-strength CFB boiler high-aluminum refractory plastic material

A plasticable and high-strength technology, which is applied in the field of high-strength CFB boiler high-alumina refractory plastics, can solve the problems of further improvement in wear resistance, increased wear, and high sintering temperature, achieving high density, increased strength, The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

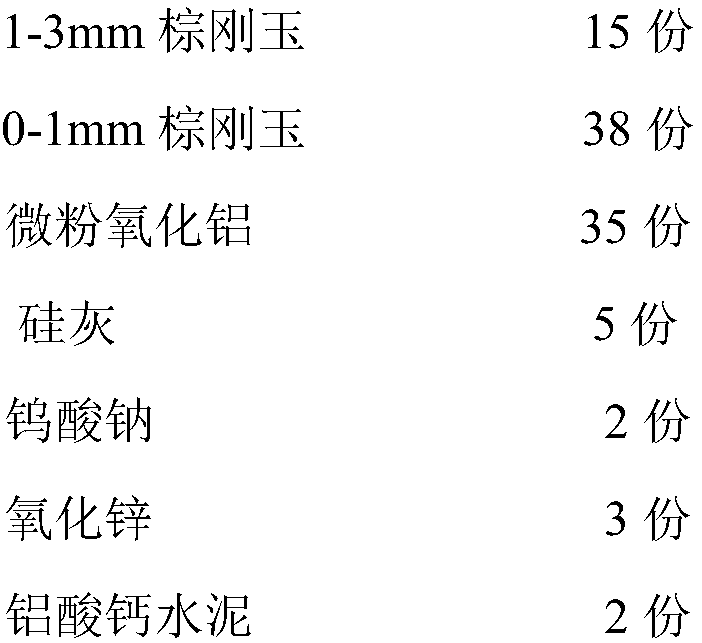

[0034] A high-strength CFB boiler refractory plastic, including a filler (B material) and a rubber material (A material) with a weight ratio of 100:16.3; wherein the rubber material (A material) is aluminum dihydrogen phosphate with a density of 1.65g / ml Solution; filler (B material) comprises the component of following weight fraction:

[0035]

[0036] The preparation method comprises the following steps:

[0037] Weigh each substance in the filler according to the mass ratio, mix evenly and add sizing material accounting for 16.3% of the mass of material B and continue mixing to make them stick together to form a soft refractory plastic with construction property. The prepared refractory plastic is compacted and solidified in a mold of 40×40×160 mm. After demoulding, it is calcined at 900° C. for 3 hours, and the compressive strength reaches 185 MPa, and the flexural strength reaches 33 MPa.

Embodiment 2

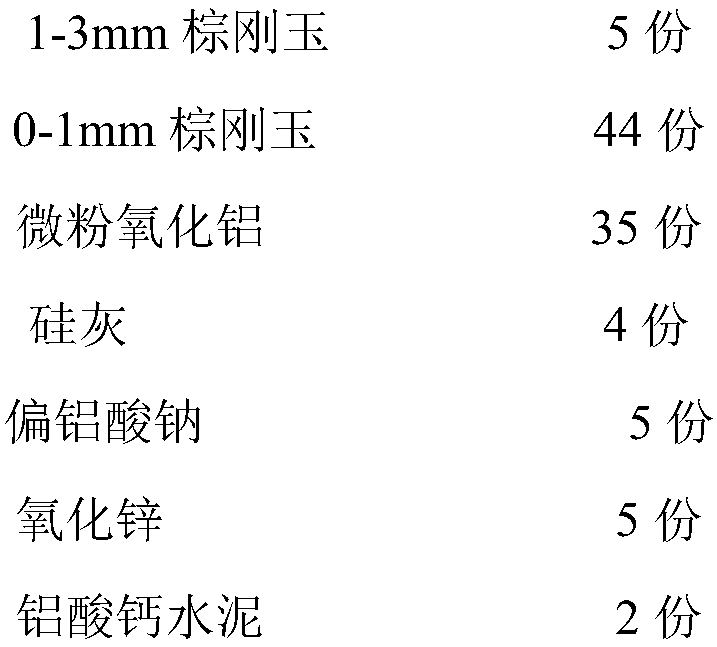

[0039] A high-strength CFB boiler refractory plastic, including a filler (B material) and a rubber material (A material) with a weight ratio of 100:22; wherein the rubber material (A material) is aluminum dihydrogen phosphate with a density of 1.45g / ml Solution; filler (B material) comprises the component of following weight fraction:

[0040]

[0041] The refractory plastic of this embodiment mainly uses aluminum dihydrogen phosphate as a binder, and does not need to add other components in the liquid-phase rubber made; the concentration of material A and the mixing ratio with material B can effectively Improve the strength of refractory plastic; through the reaction of divalent metal oxide and aluminum oxide, the strength of the repair material is improved; the corundum aggregate also effectively increases the density and hardness of the repair material; adding silica fume improves the construction performance of the repair material (fluidity and plasticity), and improve ...

Embodiment 3

[0045]A high-strength CFB boiler refractory plastic, including a filler (B material) and a rubber material (A material) with a weight ratio of 100:16; wherein the rubber material (A material) is aluminum dihydrogen phosphate with a density of 1.7g / ml Solution; filler (B material) comprises the component of following weight fraction:

[0046]

[0047]

[0048] The preparation method comprises the following steps:

[0049] Weigh each substance in the filler according to the mass ratio, mix evenly and add sizing material accounting for 16% of the mass of material B and continue mixing to make them stick together to form a soft refractory plastic with construction property. The prepared refractory plastic is compacted and solidified in a mold of 40×40×160 mm. After demoulding, it is calcined at 900° C. for 3 hours, and the compressive strength reaches 195 MPa, and the flexural strength reaches 35 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com