Energy-saving heat-preservation door/window auxiliary frame material and preparation method thereof

A frame, door and window technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of poor thermal insulation performance, high thermal conductivity, etc., and achieve excellent mechanical shock resistance, low thermal conductivity, durable good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

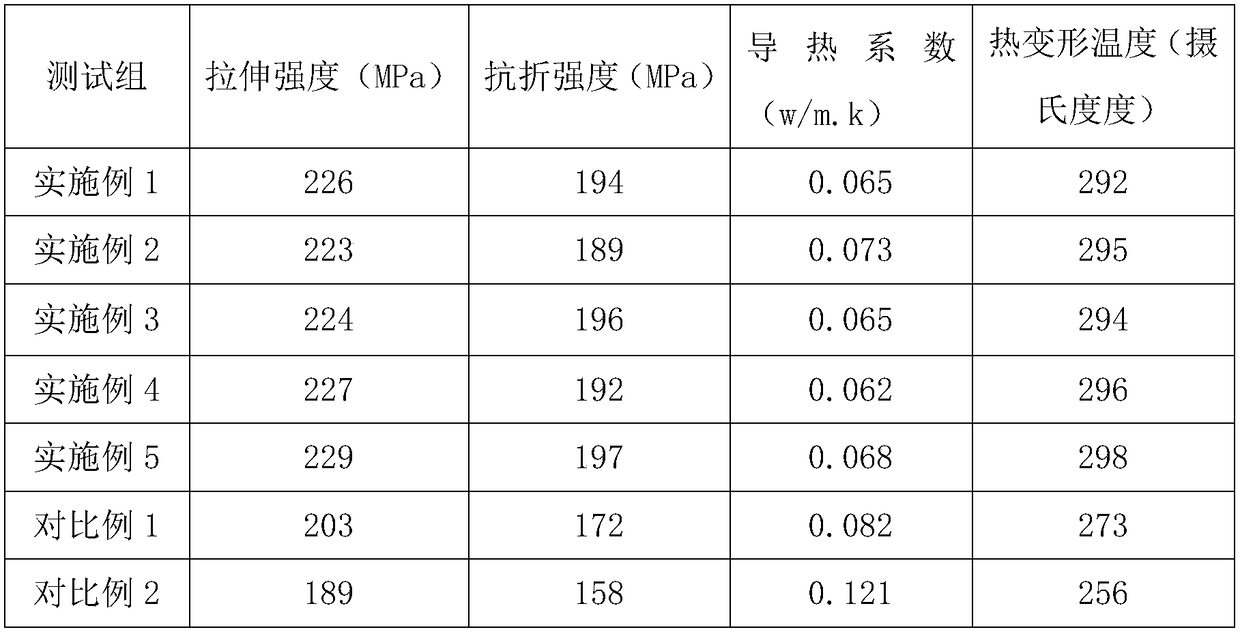

Examples

Embodiment 1

[0033] An energy-saving and thermal insulation door and window frame material, comprising the following raw materials in parts by weight;

[0034] 90 parts of polyvinyl chloride, 4 parts of tung oil, 3 parts of propylene oxide, 5 parts of nano-ceramic hollow particles, 12 parts of wood powder, 4 parts of nano-titanium dioxide, 8 parts of modified shell powder, 4 parts of rosin, 3 parts of phosphite, 15 parts of composite flame retardant, 0.8 parts of silane coupling agent KH-5500 and 3 parts of foaming agent;

[0035] The composite flame retardant is composed of tributyl phosphate, zinc borate, aluminum hydroxide and magnesium hydroxide in a mass ratio of 3:1:20:20.

[0036] The foaming agent is composed of azobisisobutyronitrile, nano-zinc oxide and sodium bicarbonate in a mass ratio of 2:1:1.5.

[0037] The preparation method of modified shell powder is as follows:

[0038] (1) Wash the shells and place them in a 5% hydrochloric acid solution by mass, stir and soak for 30 ...

Embodiment 2

[0051] An energy-saving and thermal insulation door and window frame material, comprising the following raw materials in parts by weight;

[0052] 100 parts of polyvinyl chloride, 9 parts of tung oil, 6 parts of propylene oxide, 12 parts of nano-ceramic hollow particles, 18 parts of wood powder, 9 parts of nano-titanium dioxide, 15 parts of modified shell powder, 10 parts of rosin, 7 parts of phosphite, 22 parts of composite flame retardant, 1.4 parts of silane coupling agent KH-5500 and 7 parts of foaming agent;

[0053] The composite flame retardant is composed of tributyl phosphate, zinc borate, aluminum hydroxide and magnesium hydroxide in a mass ratio of 3:1:20:20.

[0054] The foaming agent is composed of azobisisobutyronitrile, nano-zinc oxide and sodium bicarbonate in a mass ratio of 2:1:1.5.

[0055] The preparation method of modified shell powder is as follows:

[0056] (1) Wash the shells and place them in a 5% by mass hydrochloric acid solution, stir and soak for...

Embodiment 3

[0069] An energy-saving and thermal insulation door and window frame material, comprising the following raw materials in parts by weight;

[0070] 92 parts of polyvinyl chloride, 5 parts of tung oil, 4 parts of propylene oxide, 7 parts of nano-ceramic hollow particles, 14 parts of wood powder, 5 parts of nano-titanium dioxide, 10 parts of modified shell powder, 5 parts of rosin, 4 parts of phosphite, 17 parts of composite flame retardant, 1 part of silane coupling agent KH-5501 and 5 parts of foaming agent;

[0071] The composite flame retardant is composed of tributyl phosphate, zinc borate, aluminum hydroxide and magnesium hydroxide in a mass ratio of 3:1:20:20.

[0072] The foaming agent is composed of azobisisobutyronitrile, nano-zinc oxide and sodium bicarbonate in a mass ratio of 2:1:1.5.

[0073] The preparation method of modified shell powder is as follows:

[0074] (1) Wash the shells and place them in a 5% hydrochloric acid solution by mass, stir and soak for 35 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com