A kind of production line of albite powder

A feldspar powder and production line technology, applied in the direction of silicate, alkali metal silicate, etc., can solve the problem of unclean removal of iron-containing substances, and achieve the effect of improving purity, good wear resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

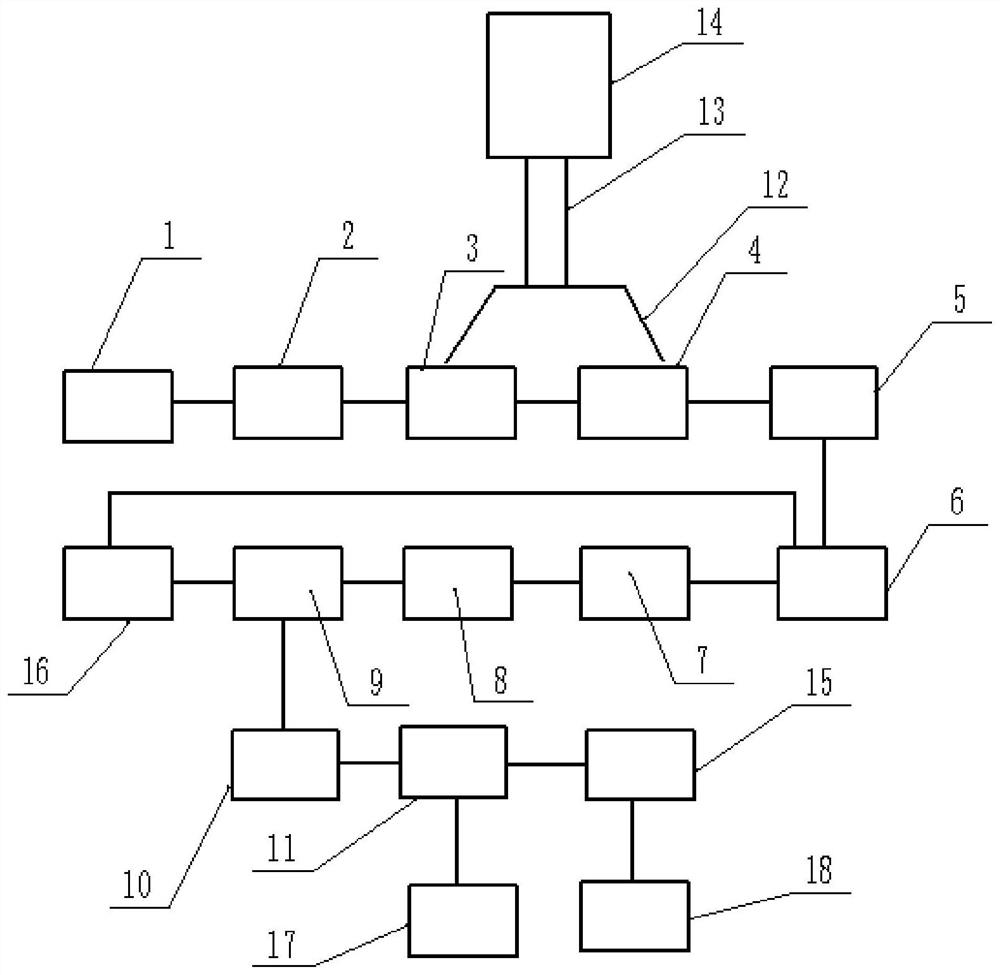

[0028] See figure 1 , a production line for albite powder, including a crushing part, a powder grinding part, a screening and impurity removal part, a flotation part, a finished product output part and a gas collection and dust removal part, the crushing part, the powder grinding part, the screening and impurity removal part , the flotation part, and the finished product output part are sequentially connected by a conveyor belt, and the gas-collecting and dust-removing part is arranged above the powder-milling part.

[0029] The crushing part includes a jaw crusher 1 and a cone crusher 2 connected by a conveyor belt.

[0030] The milling part includes a Raymond mill 3 and a ball mill 4 connected by a conveyor belt, the Raymond mill 3 is connected with the cone crusher 2 by a conveyor belt, and the ball-to-material ratio of the ball mill 4 is 2-3: 1. In this example, it is preferably 3:1, so that the albite feldspar can be fully ball-milled and the fineness of the albite felds...

Embodiment 2

[0044] In this embodiment, except that the components of the raw materials for making the wear-resistant layer are different, everything else is the same as that in Embodiment 1.

[0045] In this embodiment, the wear-resistant layer is made of raw materials including the following parts by weight: 36 parts of nitrile rubber, 30 parts of epoxy resin, 18 parts of polyvinyl chloride resin, 18 parts of aluminate, 10 parts of aluminum oxide, 8 parts of boron nitride, 8 parts of sodium sulfate, 8 parts of aluminum hydroxide, 6 parts of tungsten carbide and 5 parts of glass fiber.

Embodiment 3

[0047] In this embodiment, except that the components of the raw materials for making the wear-resistant layer are different, everything else is the same as that in Embodiment 1.

[0048] In this embodiment, the wear-resistant layer is made of raw materials including the following parts by weight: 30 parts of nitrile rubber, 25 parts of epoxy resin, 15 parts of polyvinyl chloride resin, 14 parts of aluminate, 8 parts of aluminum oxide, 6 parts of boron nitride, 6 parts of sodium sulfate, 6 parts of aluminum hydroxide, 5 parts of tungsten carbide and 3 parts of glass fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com