Copper oxide-tin oxide core-shell nanowire structure-based gas sensitive nano material, preparation process and application thereof

A core-shell nanotechnology and preparation technology, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of weakened sensor sensitivity and lifespan, incompatibility with biocompatibility, high preparation cost, etc., to achieve improved gas-sensing performance, excellent gas-sensing performance, preparation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

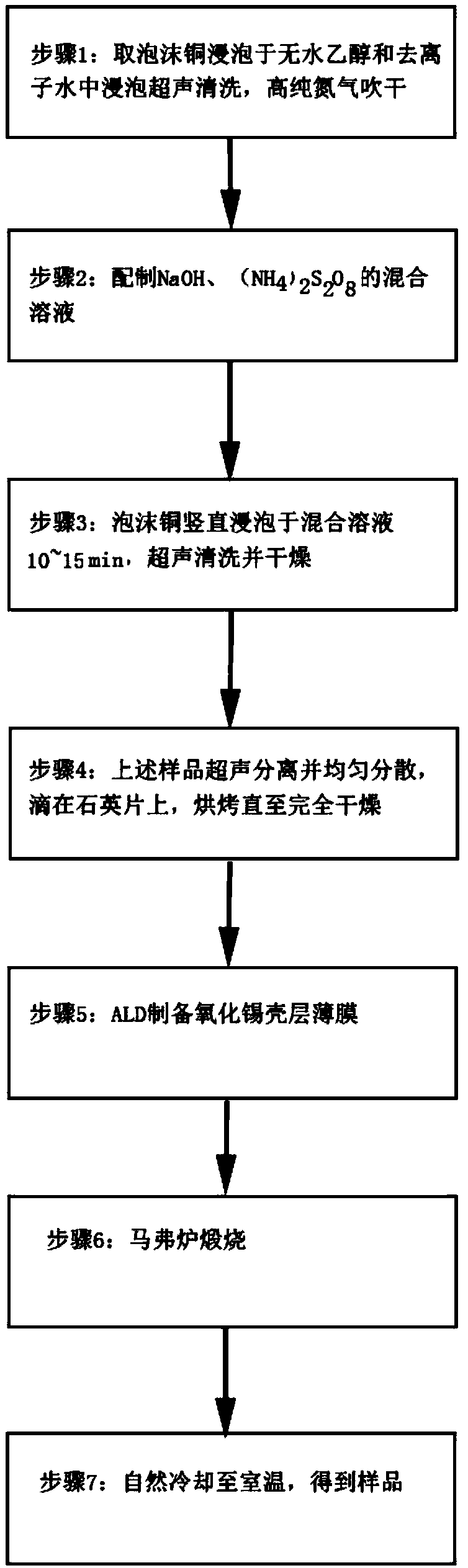

[0035] a based on p - n The preparation process of the gas-sensitive nanomaterial with copper oxide-tin oxide core-shell nanowire structure comprises the following steps:

[0036] (1) Take a piece of orange-red foam copper with a size of 1.5 cm × 3.5 cm as the substrate and source material, soak it in absolute ethanol and deionized water for 10 min, and then blow it dry with high-purity nitrogen at room temperature.

[0037] (2) Prepare NaOH concentration to be 1.25 mol / L, (NH 4 ) 2 S 2 o 8 The mixed solution with a concentration of 0.0625 mol / L was used as the reaction solution.

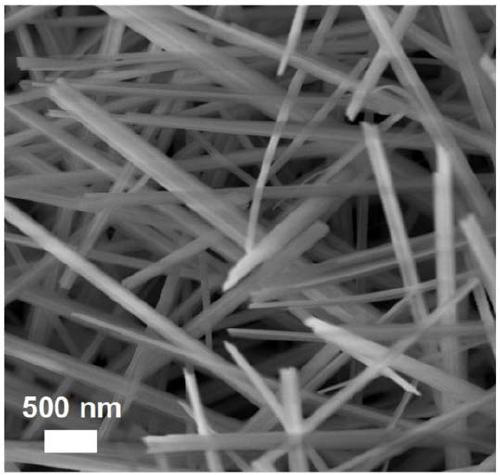

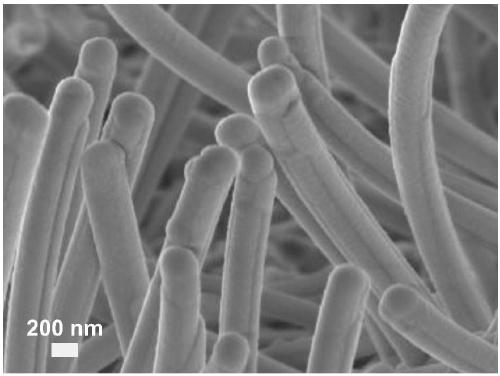

[0038] (3) Soak the cleaned and dried copper foam vertically in the above reaction solution for 10 min, take it out, and then ultrasonically clean it with absolute ethanol and deionized water for 3 times, each time for 3 min. After drying with high-purity nitrogen, light blue Cu(OH) with an average length of 8 μm and an average diameter of 132 nm grew on the surface of the foamed copper. 2 na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com