A method for continuously synthesizing 2,3,3,3-tetrafluoropropene in gas phase

A tetrafluoropropene, continuous process technology, applied in 2 fields, can solve the problems of low tetrafluoropropene yield, difficult catalyst preparation, etc., and achieve the effects of low equipment investment cost, wide industrial application prospects, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

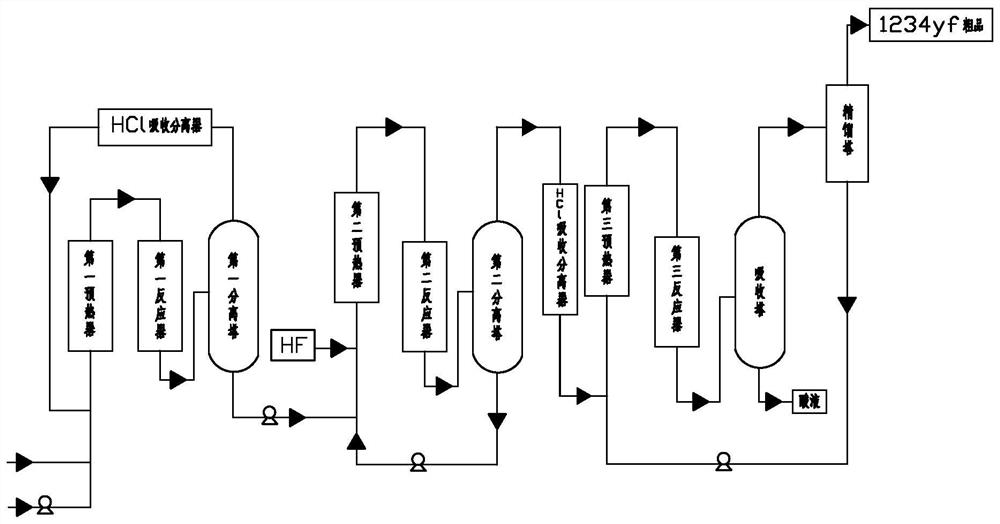

Image

Examples

Embodiment 1

[0027] Chloromethane and tetrachlorethylene are mixed and preheated to 140°C by the first preheater, and then enter the first reactor of a stainless steel alloy tube with a length of 1.5m and an inner diameter of 80mm. The catalyst CuCl-MgCl 2 / Al 2 o 3 In the presence of the reaction, the reaction temperature is 220°C, the reaction pressure is 0.2MPa, and the space velocity is 500h -1 , the feed molar ratio of monochloromethane and tetrachloroethylene is 2:1, and the product mixture is obtained; the product mixture enters the first separation tower for separation, and the by-product HCl and a small amount of unreacted monochloromethane and tetrachloroethylene are separated from the top of the tower The mixture of the tower top product is recycled to the first reactor after being absorbed and separated by HCl, and the tower bottom liquid containing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene is obtained ;

[0028]Pump the 1,1,1,2,2-pentachloropropane and 2,3...

Embodiment 2

[0033] Chloromethane and tetrachlorethylene are mixed and preheated to 140°C by the first preheater, and then enter the first reactor of a stainless steel alloy tube with a length of 1.5m and an inner diameter of 80mm. The catalyst CuCl-MgCl 2 / Al 2 o 3 In the presence of the reaction, the reaction temperature is 240°C, the reaction pressure is 0.3MPa, and the space velocity is 600h -1 , the feeding molar ratio of monochloromethane and tetrachloroethylene is 4:1, obtains the product mixture; The product mixture enters the first separation tower for separation, and the by-product HCl and a small amount of unreacted monochloromethane and tetrachloroethylene are separated from the top of the tower The mixture of the tower top product is recycled to the first reactor after being absorbed and separated by HCl, and the tower bottom liquid containing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene is obtained ;

[0034] Pump the 1,1,1,2,2-pentachloropropane and 2,3,3,3...

Embodiment 3

[0039] Chloromethane and tetrachlorethylene are mixed and preheated to 140°C by the first preheater, and then enter the first reactor of a stainless steel alloy tube with a length of 1.5m and an inner diameter of 80mm. The catalyst CuCl-MgCl 2 / Al 2 o 3 In the presence of the reaction, the reaction temperature is 220°C, the reaction pressure is 0.4MPa, and the space velocity is 500h -1 , the feed molar ratio of monochloromethane and tetrachloroethylene is 10:1, and the product mixture is obtained; the product mixture enters the first separation tower for separation, and the by-product HCl and a small amount of unreacted monochloromethane and tetrachloroethylene are separated from the top of the tower The mixture of the tower top product is recycled to the first reactor after being absorbed and separated by HCl, and the tower bottom liquid containing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene is obtained ;

[0040] Pump the 1,1,1,2,2-pentachloropropane and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com