A preparation method for producing high-purity copper powder and recovering crystalline aluminum chloride by using copper chloride-containing waste etching solution

A technology for crystallizing aluminum chloride and waste etching solution, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of complex process, high energy consumption, low efficiency, etc., and achieves simple production process, no increase in liquid volume, economical good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

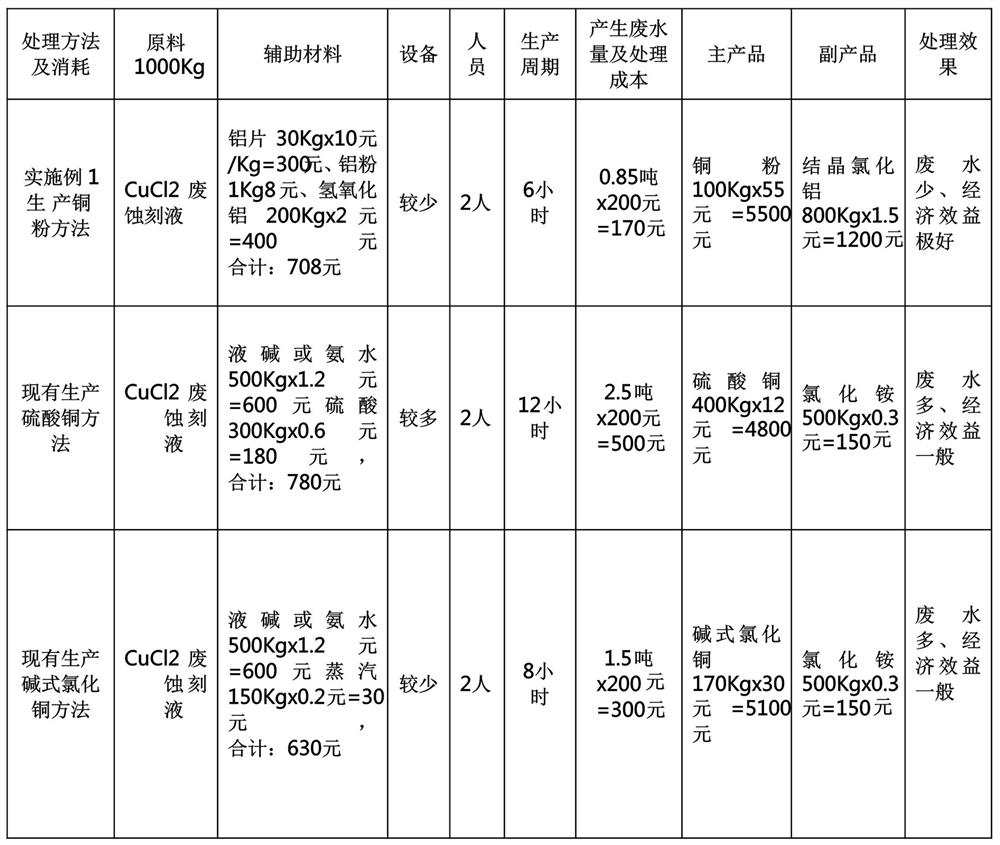

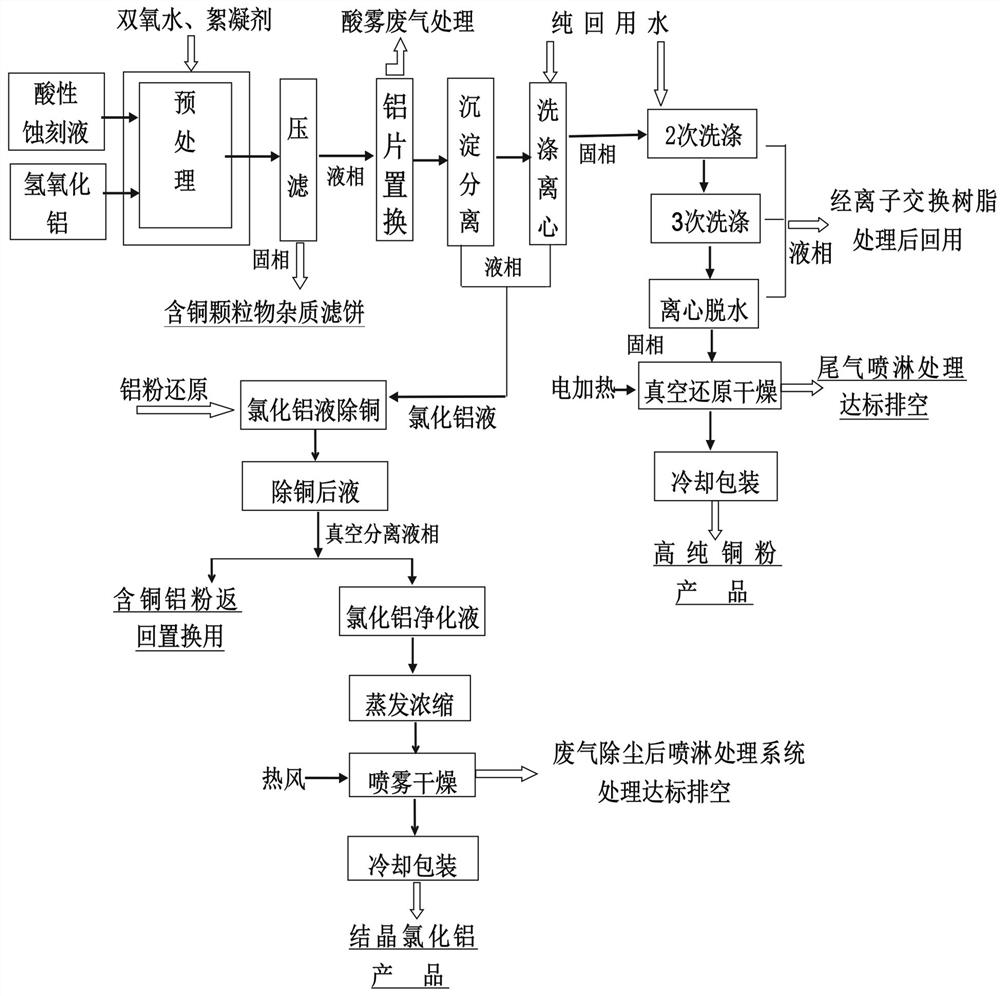

[0023] Example 1, such as figure 1 Shown, a kind of preparation method that produces high-purity copper powder and reclaims crystalline aluminum chloride with copper chloride waste etchant, it comprises the following steps successively.

[0024] S101, pretreatment: the collected acidic copper chloride-containing waste etching solution is input into the reaction tank, and then in each liter of acidic copper chloride-containing waste etching solution, 1.6 g of hydrogen peroxide with a mass fraction of 27.5% and the purity of aluminum oxide of 63 120g of aluminum hydroxide was stirred for neutralization reaction, and then PAM was added until the pH of the solution was controlled at 3.5 to obtain an acidic neutralization solution.

[0025] S102. Flocculation and impurity removal: Add anionic polyacrylamide flocculant to the acidic neutralization solution. The anionic polyacrylamide flocculant is a commercially available 12 million anionic polyacrylamide, stirred and dissolved with...

Embodiment 2

[0035] Embodiment 2: a kind of preparation method that produces high-purity copper powder and reclaims crystalline aluminum chloride with copper chloride waste etchant, it comprises the following steps successively.

[0036] S101, pretreatment: input the collected acidic copper chloride-containing waste etching solution into the reaction tank, and then add 2 g of hydrogen peroxide with a mass fraction of 20% to each liter of acidic copper chloride-containing waste etching solution, and the purity of aluminum oxide is 85% 150g of aluminum hydroxide was stirred for neutralization reaction, and then PAM was added until the pH of the solution was controlled at 3 to obtain an acidic neutralization solution.

[0037] S102. Flocculation and impurity removal: add anionic polyacrylamide flocculant to the acidic neutralization solution, the anionic polyacrylamide flocculant is commercially available 8 million anionic polyacrylamide, stirred and dissolved with water to form a 0.5g / L solut...

Embodiment 3

[0044] Embodiment 3: a kind of preparation method that produces high-purity copper powder and reclaims crystalline aluminum chloride with copper chloride waste etchant, it comprises the following steps successively.

[0045] S101, pretreatment: input the collected acidic copper chloride-containing waste etching solution into the reaction tank, then add 1 g of hydrogen peroxide and 150 g of aluminum oxide with a mass fraction of 30% to each liter of acidic copper chloride-containing waste etching solution and stir for neutralization reaction, and then add PAM until the pH of the solution is controlled at 3.8 to obtain an acidic neutralizing solution.

[0046] S102. Flocculation and impurity removal: add anionic polyacrylamide flocculant to the acidic neutralization solution, the anionic polyacrylamide flocculant is commercially available 9.5 million anionic polyacrylamide and stir it with water to form a 0.35g / L solution; anionic polyacrylamide The amount of flocculant added is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com