Preparation method for improving mechanical property of aluminum-based composite through synergistic reinforcement of carbon nanotube and graphene

A technology of carbon nanotubes and composite materials, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems that carbon nanotubes and graphene-reinforced aluminum-based composite materials have no effect, and achieve improvement Effects of load transfer efficiency, strength improvement, and mechanical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

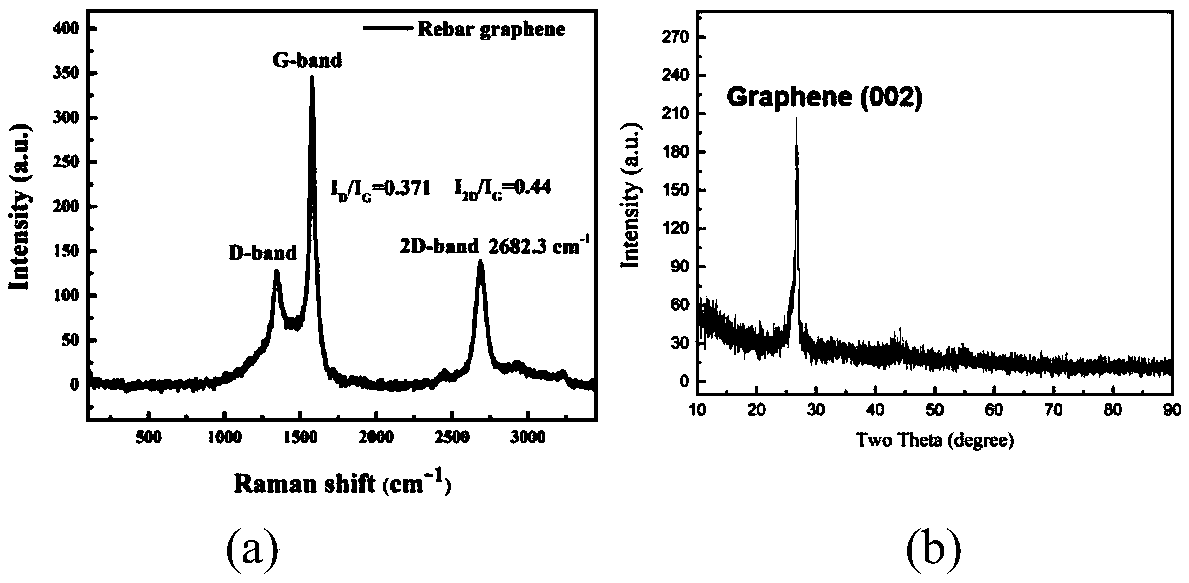

Method used

Image

Examples

Embodiment 1

[0020] (1) First, nickel powder, sucrose and dispersant are placed in 150ml deionized water, then the weighed carbon nanotubes are placed in 25ml water, put into a cell pulverizer for ultrasonic dispersion, and then the carbon nanotube solution is placed in Put it into the mixed solution of nickel powder, sucrose and dispersant, stir and heat in a stirrer, the heating temperature is 120°C, when the water evaporates, the mixed powder is obtained. Then the mixed powder was dried in a vacuum oven at a temperature of 70°C.

[0021] (2) Put the mixed powder obtained in step 1 into a tube furnace for chemical synthesis, the synthesis atmosphere is a mixed gas with a ratio of argon to hydrogen of 2:1 to 3:1, the synthesis temperature is 950°C, and the heating rate is 5°C / min~10°C / min. After the reaction, the sample is cooled rapidly to obtain a mixed powder. Put the powder obtained after the reaction into the ferric chloride corrosion solution to fully corrode, knowing that the nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com