Preparation and Mass Spectrometry Application of a Diheteroatom-doped Graphene/Porous Carbon Composite

A technology of graphene and composites, applied in the field of analytical chemistry, to achieve the effects of good conductivity, good ultraviolet absorption capacity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

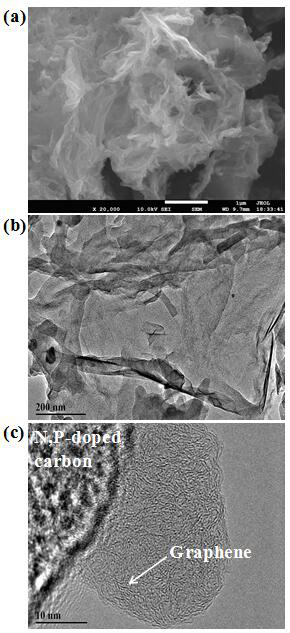

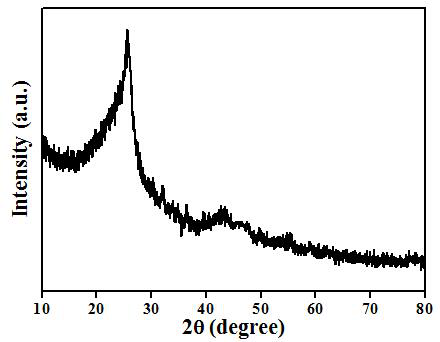

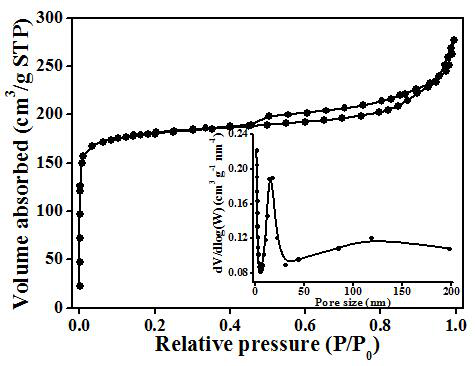

Embodiment 1

[0052] (1) Under stirring and ice bath conditions, 0.921 mL of 50% phytic acid solution was continuously added dropwise to 2 mL of graphene solution with a mass concentration of 6 mg / mL, and then 0.458 mL of aniline solution was added dropwise , and set aside after mixing evenly. (2) In the above mixed solution, quickly add 1.25 mmol of ammonium persulfate solution under stirring conditions, and continue to keep it under ice bath conditions for 12 hours. After the graphene / polyaniline gel is initially formed, further use The dialysis bag with MW~14,000 MW dialyzes the unreacted aniline and phytic acid solution to obtain a pure graphene / polyaniline gel, which is finally freeze-dried under liquid nitrogen to obtain a solid powder of graphene / polyaniline. (3) The obtained graphene / polyaniline composite was heated to 900 °C for 2 h at a heating rate of 5 °C / min in an argon atmosphere, and then lowered to room temperature to obtain a three-dimensional co-doped nitrogen and phosphor...

Embodiment 2

[0055] (1) Under the condition of stirring and ice bath, 0.460 mL of 50% phytic acid solution was continuously added dropwise to 2 mL of graphene solution with a mass concentration of 6 mg / mL, and then 0.458 mL of aniline solution was added dropwise , and set aside after mixing evenly. (2) In the above mixed solution, quickly add 1.25 mmol of ammonium persulfate solution under stirring conditions, and continue to keep it under ice bath conditions for 12 hours. After the graphene / polyaniline gel is initially formed, further use The dialysis bag with MW~14,000 MW dialyzes the unreacted aniline and phytic acid solution to obtain a pure graphene / polyaniline gel, which is finally freeze-dried under liquid nitrogen to obtain a solid powder of graphene / polyaniline. (3) The obtained graphene / polyaniline composite was heated to 900 °C for 2 h at a heating rate of 5 °C / min in an argon atmosphere, and then lowered to room temperature to obtain a three-dimensional co-doped nitrogen and ph...

Embodiment 3

[0057] (1) Under stirring and ice bath conditions, 0.460 mL of 50% phytic acid solution was continuously added dropwise to 2 mL of graphene solution with a mass concentration of 6 mg / mL, and then 0.916 mL of aniline solution was added dropwise , and set aside after mixing evenly. (2) In the above mixed solution, quickly add 1.25 mmol of ammonium persulfate solution under stirring conditions, and continue to keep it under ice bath conditions for 12 hours. After the graphene / polyaniline gel is initially formed, further use The dialysis bag with MW~14,000 MW dialyzes the unreacted aniline and phytic acid solution to obtain a pure graphene / polyaniline gel, which is finally freeze-dried under liquid nitrogen to obtain a solid powder of graphene / polyaniline. (3) The obtained graphene / polyaniline composite was heated to 900 °C for 2 h at a heating rate of 5 °C / min in an argon atmosphere, and then lowered to room temperature to obtain a three-dimensional co-doped nitrogen and phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com