Positive electrode composite material of lithium ion battery and all-solid-state battery containing the same

A lithium-ion battery, all-solid-state battery technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of poor interface compatibility, low ionic conductivity, and high battery preparation costs, reducing direct contact, improving Interface problems, the effect of enhancing ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

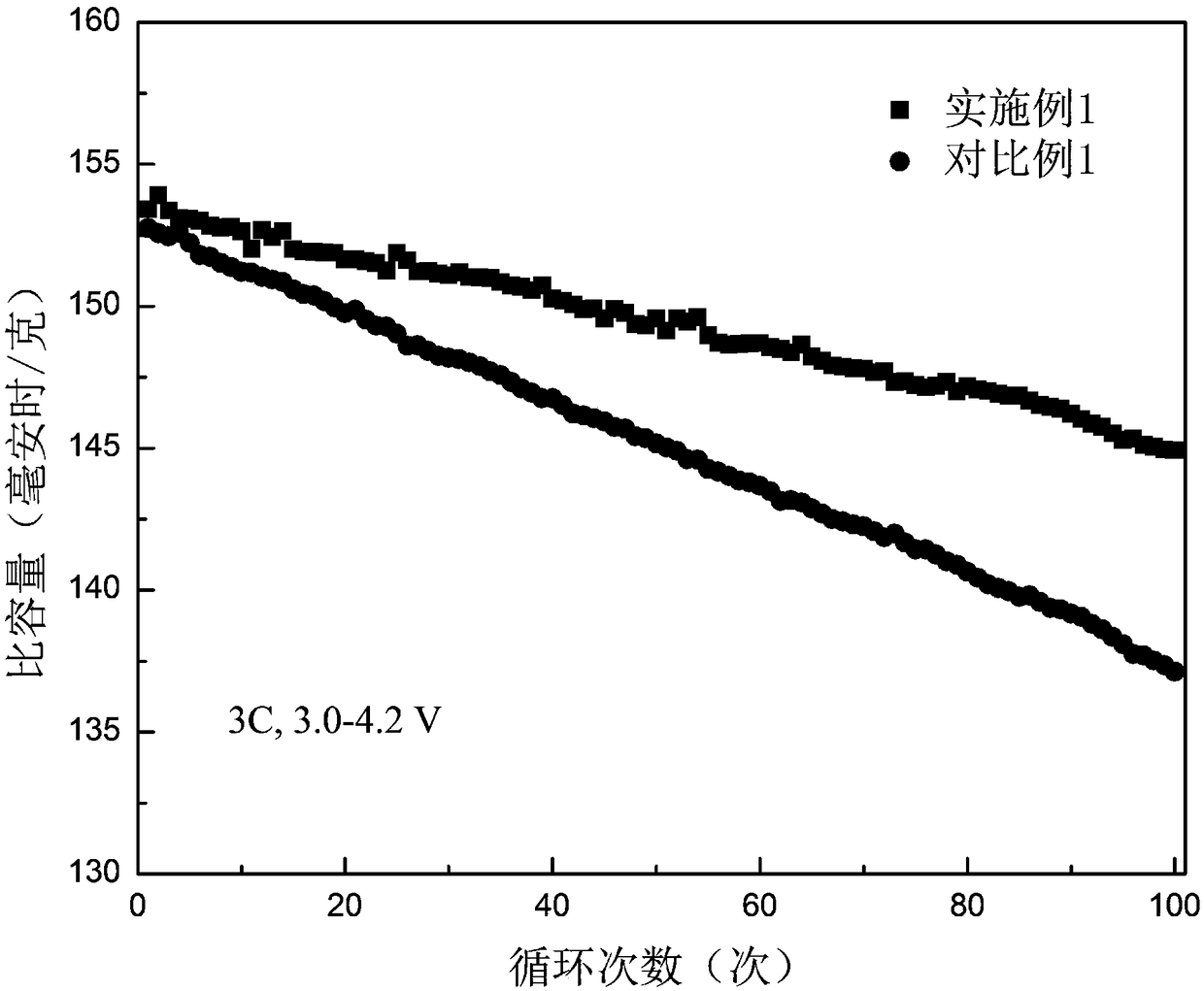

Embodiment 1

[0036] The preparation process of the all-solid-state battery is as follows:

[0037] The first step, the preparation of the cathode composite material: according to 3LiBH 4 -LiI and lithium nickel cobalt manganese oxide 523 mass ratio is 5:100 and weighed, the 3LiBH 4 -LiI is dissolved in N-methylpyrrolidone. After it is completely dissolved, add nickel-cobalt lithium manganese oxide 523, stir evenly in a high-speed disperser, and then put it in a vacuum drying oven to dry until the solvent is completely evaporated. Under the atmosphere at 500°C, calcined for 6 hours, and cooled with the furnace to obtain a positive electrode composite material with a core-shell structure.

[0038] The second step, the preparation of the positive electrode sheet: weigh the positive electrode composite material obtained in the first step, acetylene black, and polyvinylidene fluoride in a mass ratio of 94:3:3, and then add polyvinylidene fluoride to the N-methyl Disperse in pyrrolidone. After...

Embodiment 2

[0043] The first step, the preparation of the cathode composite material: according to 3LiBH 4 -LiI and LiCoO 2 The mass ratio is 8:100, and the 3LiBH 4 -LiI is dissolved in THF, after complete dissolution, add LiCoO 2 , stirred evenly in a high-speed disperser, put it into a vacuum drying oven to dry until the solvent is completely evaporated, and calcined the obtained solid powder at 500°C for 12 hours in an argon atmosphere, and cooled with the furnace to obtain a positive electrode composite material with a core-shell structure;

[0044] The second step, the preparation of the positive electrode sheet: the positive electrode composite material obtained in the first step, Ketjen black, and polytetrafluoroethylene are weighed in a mass ratio of 92:5:3, and then the polytetrafluoroethylene is added to the N-formaldehyde After the dispersion is complete, add Ketjen black and positive electrode composite material in turn, stir evenly, adjust the slurry viscosity to 8000cps, c...

Embodiment 3

[0049] The first step, the preparation of the cathode composite material: according to 3LiBH 4 -LiI and LiFePO 4 The mass ratio is 15:100, and the 3LiBH 4 -LiI is dissolved in THF, after complete dissolution, add LiFePO 4 , stirred evenly in a high-speed disperser, then put it into a vacuum drying oven to dry until the solvent evaporates completely, calcined the obtained solid powder at 800 ° C for 1 hour in a nitrogen atmosphere, and cooled with the furnace to obtain a positive electrode composite material with a core-shell structure;

[0050] The second step, the preparation of the positive electrode sheet: the positive electrode composite material prepared in the first step, Ketjen black, and polytetrafluoroethylene are weighed in a mass ratio of 92:5:3, and then the polytetrafluoroethylene is added to the N-formaldehyde After the dispersion is complete, add Ketjen black and positive electrode composite material in turn, stir evenly, adjust the slurry viscosity to 8500cps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com