Preparation method and application of silicon carbide-based photocatalyst

A catalyst, silicon carbide technology, applied in the field of visible light photocatalyst preparation, can solve the problems of large-scale industrial application limitation, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

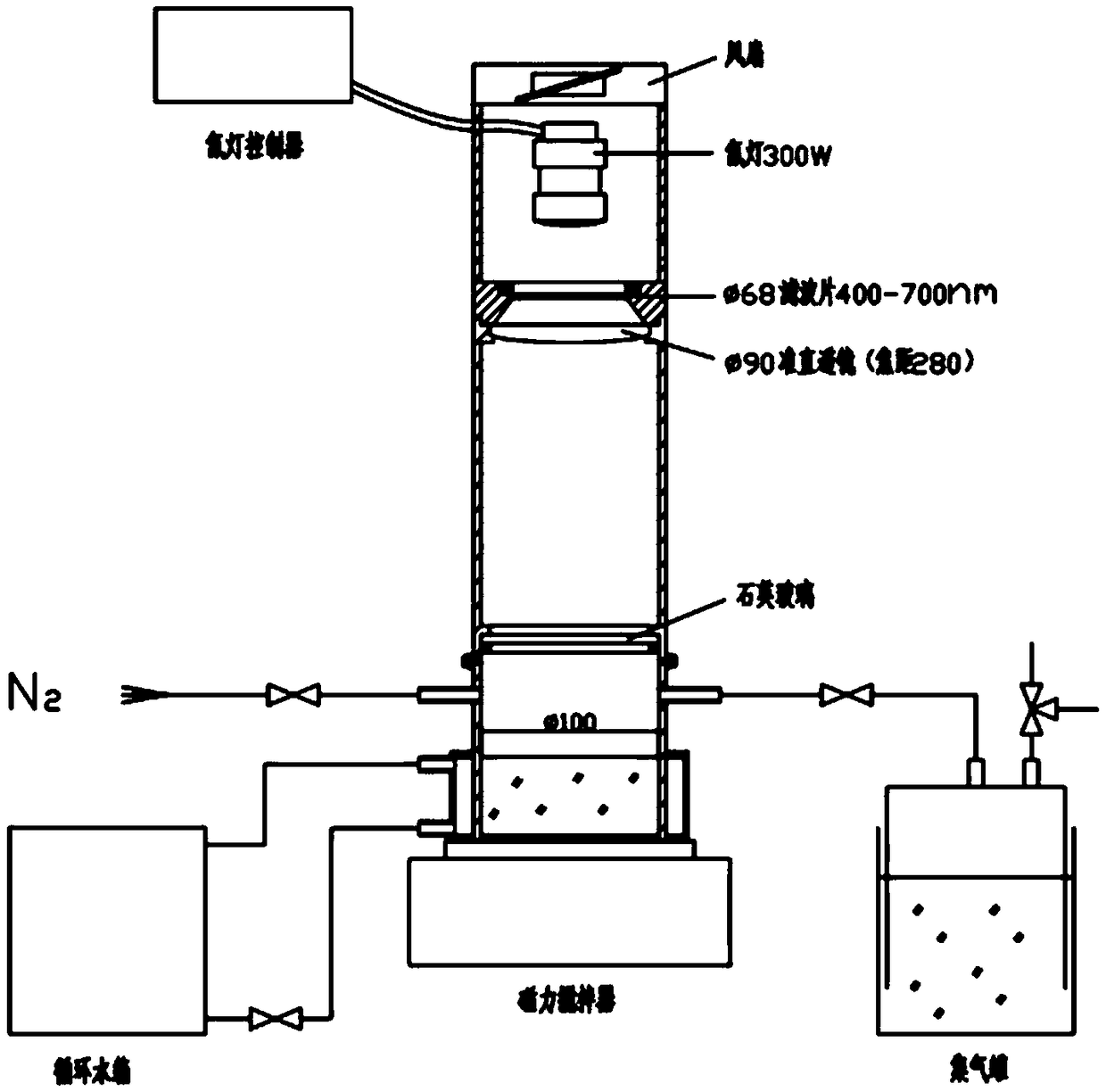

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of pure SiC: Put the SiC powder in a muffle furnace, bake it at 700°C for 5 hours, and let it cool down to room temperature naturally to remove impurity carbon; seal it in 2% HF solution and soak it overnight to remove SiO 2 and other oxides; repeated centrifugal washing with deionized water 11 times to pH = 7, placed in a vacuum oven, and vacuum-dried at 60°C;

[0026] (2) MoS 2 Suspension: at room temperature, 0.1741gMoS 2 Place in 100mL deionized water, mix well to get MoS 2 suspension;

[0027] (3) Mixing: at room temperature, to MoS 2 Add 5.0 g of pure SiC, 0.05 g of GO and 2 drops of 1-butyl-3-methylimidole hexafluorophosphate ionic liquid to the suspension in sequence, and stir it ultrasonically for 10 hours to make it evenly mixed;

[0028] (4) Preparation of silicon carbide-based double hydrogen production photocatalytic material by hydrothermal synthesis: put the above ultrasonic solution in a 300mL high-temperature reactor, react at 220°C ...

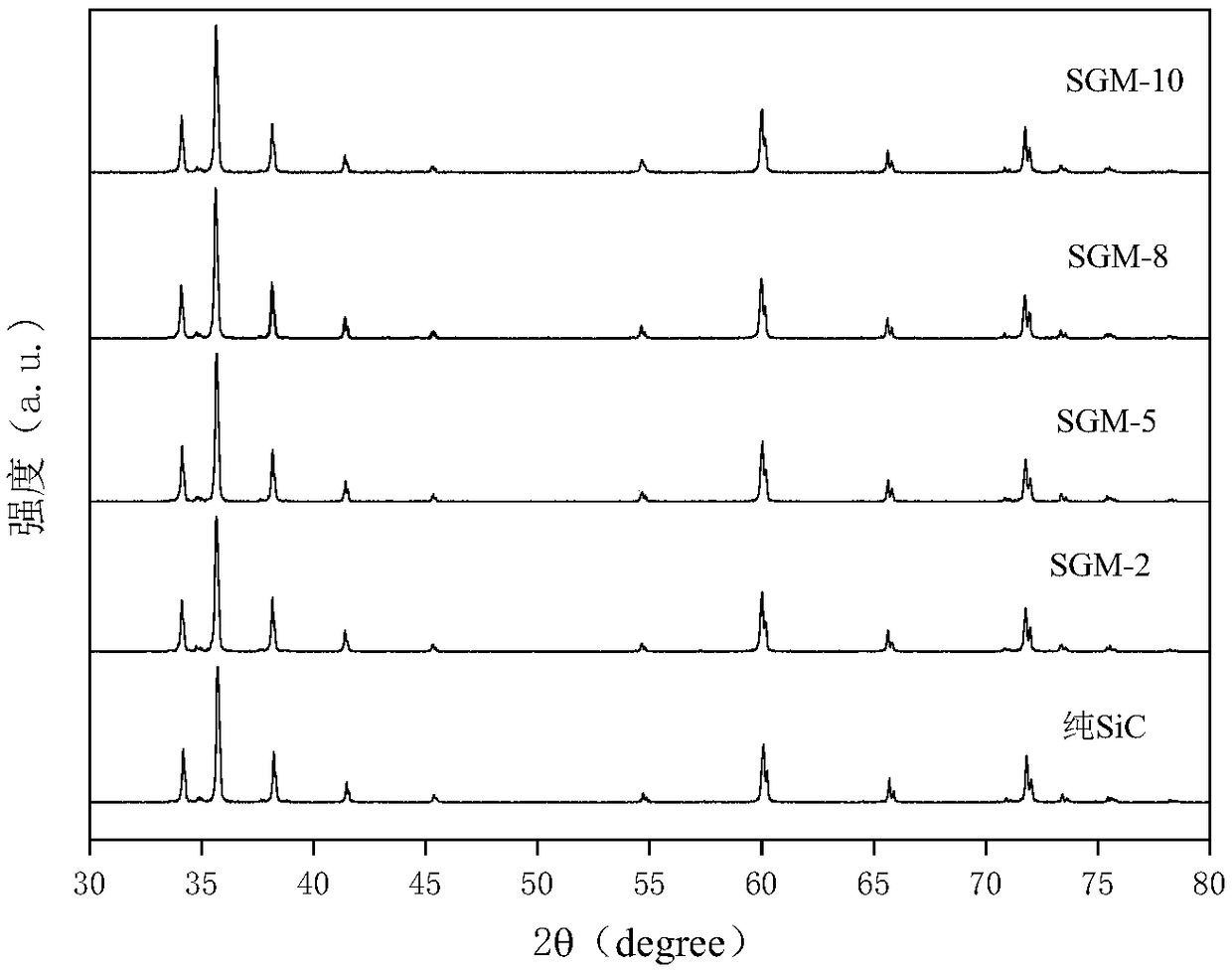

Embodiment 2

[0030] This embodiment except step (2) MoS 2 0.4590gMoS 2 , others are the same as in Example 1 to obtain SGM-5 photocatalytic material; MoS 2 The mass percentage in the hydrothermal reaction system is 5% (calculated as molybdenum element).

Embodiment 3

[0032] This embodiment except step (2) MoS 2 0.7769g MoS 2 , others are the same as in Example 1 to obtain SGM-8 photocatalytic material; MoS 2 The mass percentage in the hydrothermal reaction system is 8% (calculated as molybdenum element).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com