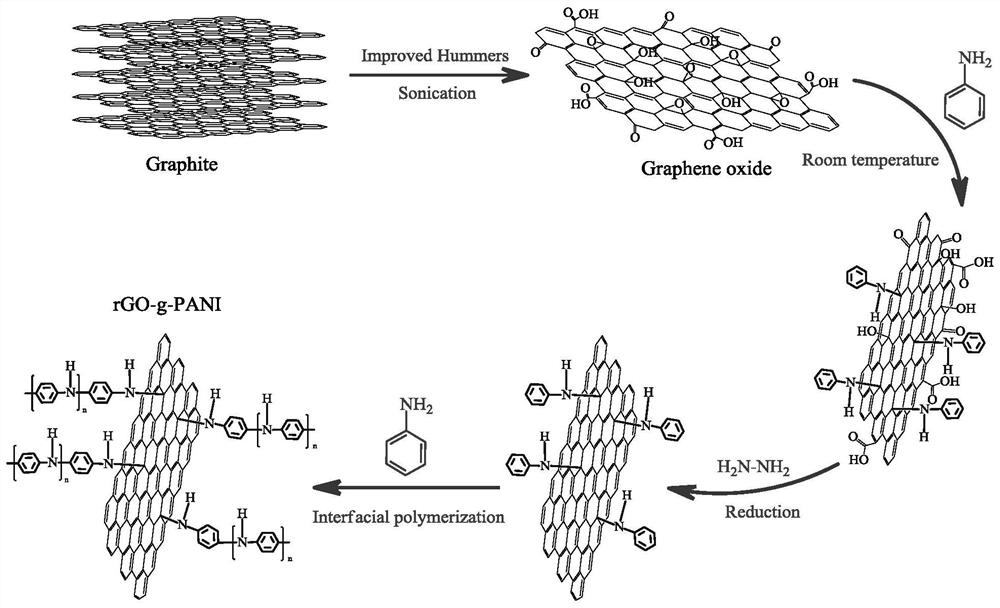

A kind of preparation method of graphene/polyaniline binary absorbing material

A wave absorbing material and graphene technology are applied in the field of preparation of graphene wave absorbing materials, which can solve the problems of low wave absorbing performance, easy phase separation of graphene and polyaniline, etc. The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 3g of graphite powder in a 1000mL three-necked flask, mix 360mL of concentrated sulfuric acid and 40mL of phosphoric acid, pour it into the flask, and keep it warm at 0°C for 30min; then weigh 18g of potassium permanganate, divide Add it to the above mixed solution in batches, then raise the temperature to 50°C for 10 hours, add it into 400mL deionized water after the reaction is completed, then add hydrogen peroxide drop by drop until the solution turns golden yellow, finally centrifuge, wash, and freeze-dry for later use;

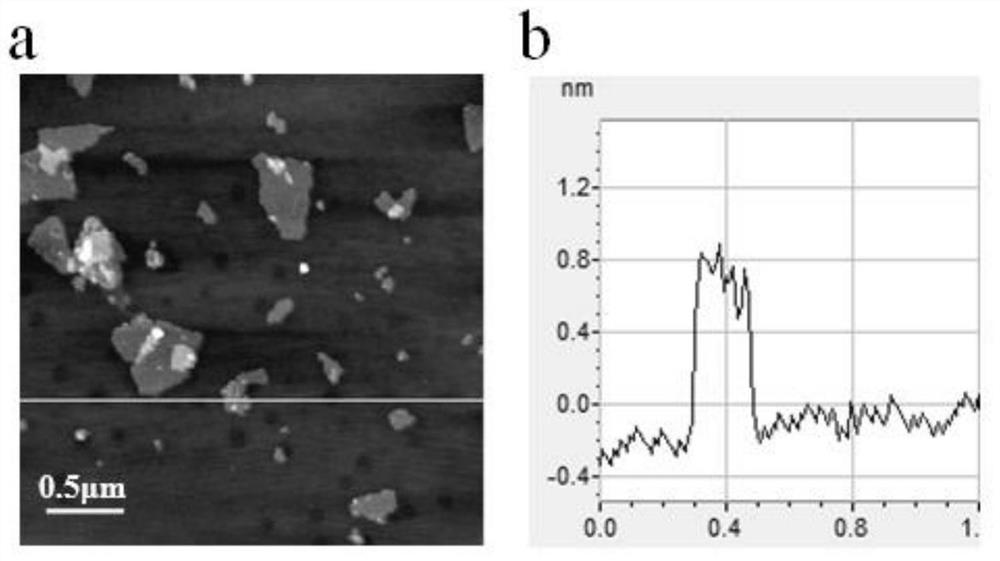

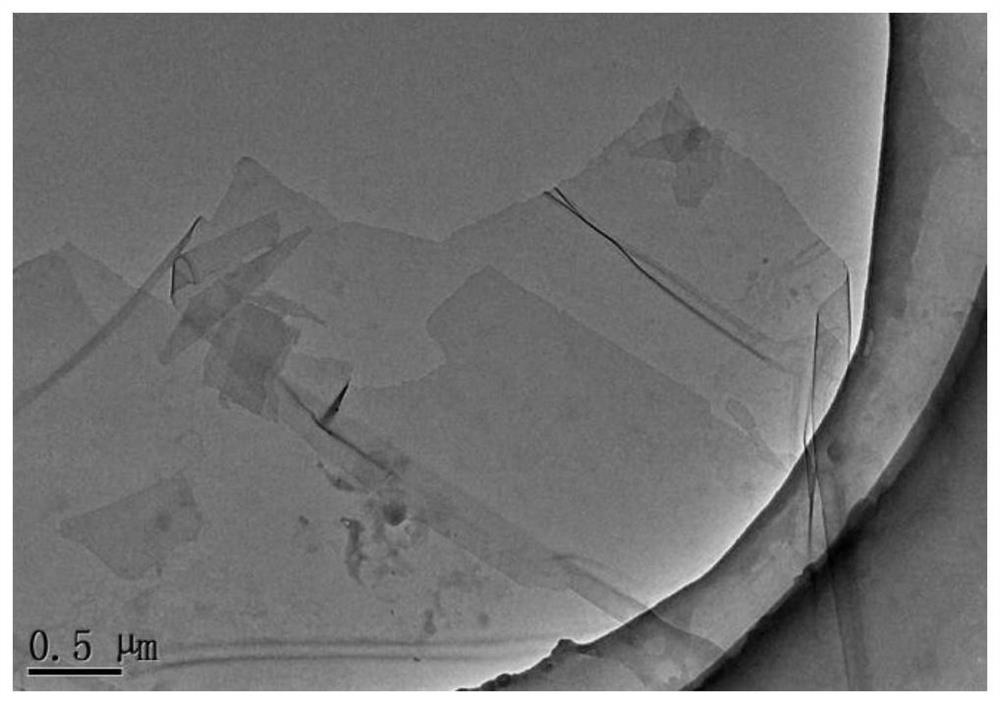

[0045] (2) Accurately weigh 200mg of graphite oxide in a 500ml beaker, then measure 100ml of deionized water and add it to the beaker, ultrasonically disperse it evenly for 0.5h, and crush it with an ultrasonic cell disruptor for 2h (power 595W) , to obtain a single-layer graphene oxide solution, and then dropwise add 1mol / L sodium hydroxide solution to the graphene oxide solution to adjust its pH value to 10, to obtain an alkaline graphen...

Embodiment 2

[0051] In step (3) of Example 1, "raise the temperature to 80°C and react for 3h" was changed to "raise the temperature to 90°C and react for 3h", and the rest were the same as in Example 1 to obtain a graphene / polyaniline binary absorbing material.

[0052] Figure 4 It shows that after aniline functional modification and hydrazine hydrate reduction, a large number of oxygen-containing functional groups on the surface of graphene oxide disappear, and at 1090cm -1 and 1649cm -1 Two peaks appeared at , corresponding to C-N bond and N-H bond, which proved that graphene oxide was successfully grafted with aniline and reduced.

Embodiment 3

[0054] "200mg of graphite oxide" in the step (2) of Example 1 to obtain a concentration of alkaline graphene oxide solution of 2mg / ml is changed to "400mg of graphite oxide" to obtain a concentration of alkaline graphene oxide solution of 4mg / ml; Change "the aniline monomer that adds 2g in the basic graphene oxide solution that obtains" into "the aniline monomer that adds 4g in the basic graphene oxide solution that obtains"; In step (3), "add 0.4mL Hydrazine hydrate (85%), warming up to 80°C, reacting for 3h" was changed to "add 0.76mL hydrazine hydrate (98%), warming up to 90°C, reacting for 3h"; ) in the hydrochloric acid solution of 50ml (concentration is 1mol / L)" is changed to "the functionalized graphene in 23.25mg step (3) is dissolved in the hydrochloric acid solution of 50ml (concentration is 1mol / L )"; the rest are the same as in Example 1 to obtain the graphene / polyaniline binary absorbing material.

[0055] Figure 5 It shows that the weight loss of graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com