A kind of graphene modification preparation method suitable for epoxy resin

A technology of graphene modification and epoxy resin, which is applied in the field of preparation of nanocomposite materials, can solve the problems of polymer matrix performance impact, reducing agent toxicity, stabilizers, protective agents and modifiers are expensive, etc., to achieve Good dispersion and compatibility, resource-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

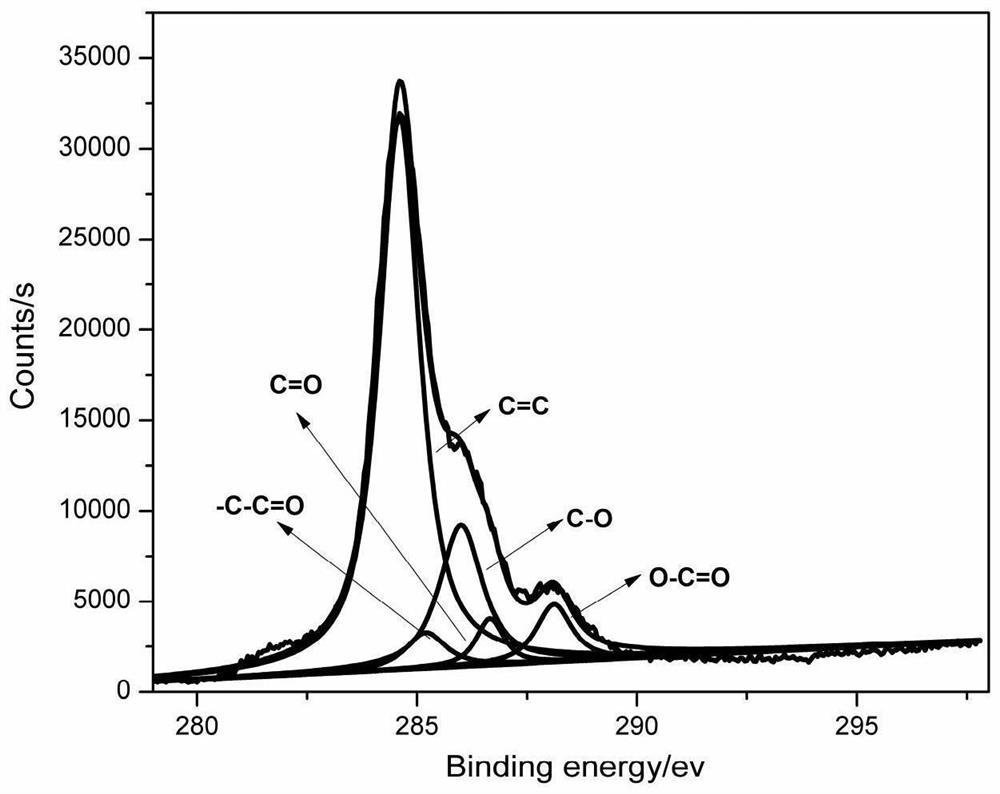

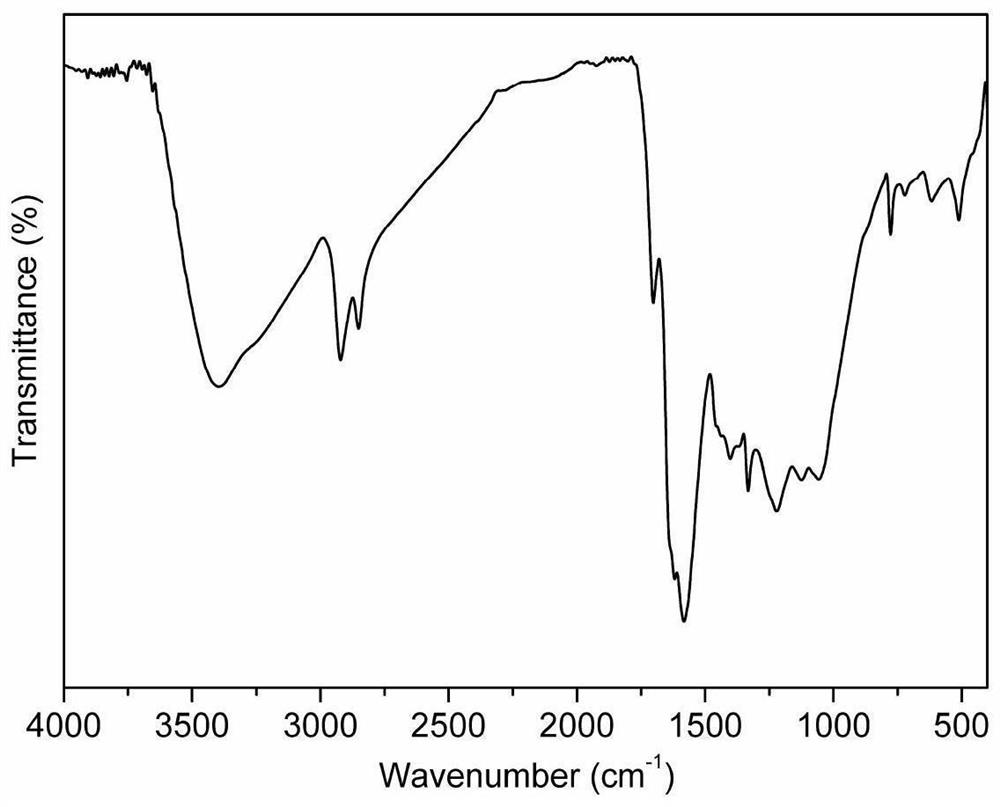

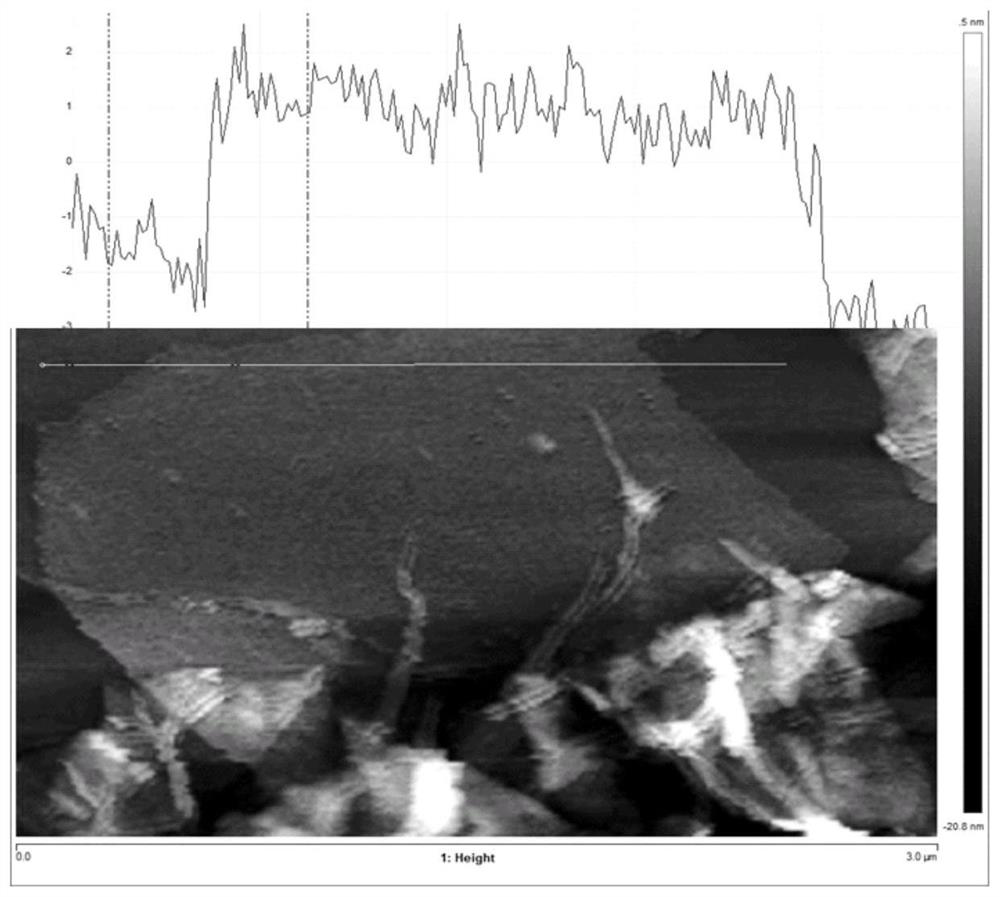

[0029] Dissolve 18.8 g urushiol, 40 g acetic acid, and 1 g concentrated sulfuric acid in 30 mL xylene, react at 30-50 ° C for 12 h, cool to room temperature, add 0.1 mol / L NaOH aqueous solution to wash until pH = 7, separate liquids, and remove water layer, take the organic phase and rotate to evaporate, remove excess acetic acid, and obtain the product epoxidized urushiol. The obtained epoxidized urushiol and the graphene oxide prepared by the Hummer method were respectively dissolved and dispersed in N,N-dimethylformamide (DMF) solvent to prepare epoxidized urushiol with a concentration of 50mg / mL and 10mg / mL graphene oxide dispersion. Equal masses of the two solutions were mixed, reacted at 100° C. for 8 hours under a nitrogen atmosphere, filtered and washed repeatedly to obtain graphene oxide reduced and modified by epoxidized urushiol. Disperse the above 0.3g of epoxidized urushiol-modified reduced graphene oxide in 100g of bisphenol A epoxy resin labeled 601-75, add 50g...

Embodiment 2

[0037]Put 18.8 g of cardanol, 40 g of formic acid and 30 mL of xylene at 30-50 ° C for 12 h, cool to room temperature, add 0.1 mol / L NaOH aqueous solution to wash until pH = 7, separate liquids, remove the water layer, take the organic phase and spin evaporate , to remove excess acetic acid to obtain the product epoxidized urushiol. The obtained epoxidized cardanol and graphene oxide prepared by the Hummer method were respectively dissolved and dispersed in N,N-dimethylformamide (DMF) solvent to prepare epoxidized cardanol with a concentration of 50mg / mL and 10mg / mL graphene oxide dispersion. Equal masses of the two solutions were mixed, reacted at 100° C. for 8 hours under a nitrogen atmosphere, filtered and repeatedly washed to obtain epoxidized cardanol-reduced and modified graphene oxide. Disperse the above 0.3g of epoxidized cardanol-modified reduced graphene oxide in 100g of bisphenol A epoxy resin labeled 601-75, add 50g of acetone and 100g of xylene, stir thoroughly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com